Preparation method of environment-friendly water-resisting composite boards

A composite board and composite board technology, applied in the direction of chemical instruments and methods, manufacturing tools, inorganic adhesives, etc., can solve the problems of low heat resistance temperature, unsuitable plane bonding, unusable bonding, etc., to achieve water absorption expansion The coefficient is small, the modification effect is remarkable, and the effect of easy operation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

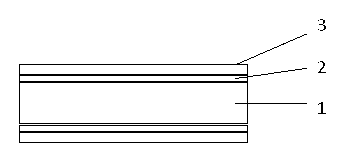

Image

Examples

Embodiment 1

[0026] 1) Environmentally friendly and water-resistant adhesives used in the preparation of composite panels:

[0027] 1) Grind quartz sand and silicon carbide into powder, pass through a 200-mesh sieve for later use;

[0028] 2) Weigh 20 parts by weight of acetone, then add 16 parts by weight of cellulose acetate into it, stir thoroughly for 15 minutes to make a cellulose acetate solution, and seal it for later use;

[0029] 3) Add 1 part by weight of dimethylolpropionic acid, 1 part by weight of dihydroxyphenylpropionic acid and 5 parts by weight of N,N-dimethylformamide into a 250ml round bottom flask protected by dry nitrogen, fully Stir for 10 minutes, add 3 parts by weight of toluene diisocyanate, 1 part by weight of hexamethylene-1,6 diisocyanate and 0.06 parts by weight of dibutyltin dilaurate, stir and react at 75-100°C for 60 minutes, reduce The solvent is removed by pressure distillation to obtain a polyurethane prepolymer;

[0030] 4) Add the polyurethane prepoly...

Embodiment 2

[0037] 1) Environmentally friendly and water-resistant adhesives used in the preparation of composite panels:

[0038] 1) Grind quartz sand and silicon carbide into powder, pass through a 200-mesh sieve for later use;

[0039] 2) Weigh 25 parts by weight of acetone, then add 20 parts by weight of cellulose acetate, stir thoroughly for 30 minutes to make a cellulose acetate solution, and seal it for later use;

[0040] 3) Add 1 part by weight of dimethylolpropionic acid, 2 parts by weight of dihydroxyphenylpropionic acid and 6 parts by weight of N,N-dimethylformamide into a 250ml round bottom flask protected by dry nitrogen, fully Stir for 15 minutes, add 5 parts by weight of toluene diisocyanate, 2 parts by weight of hexamethylene-1,6 diisocyanate and 0.08 parts by weight of dibutyltin dilaurate, stir and react at 80°C for 100 minutes, and distill under reduced pressure Remove the solvent to obtain a polyurethane prepolymer;

[0041] 4) Add the polyurethane prepolymer prepar...

Embodiment 3

[0048] 1) Grind quartz sand and silicon carbide into powder, pass through a 200-mesh sieve for later use;

[0049] 2) Weigh 30 parts by weight of acetone, then add 24 parts by weight of cellulose acetate into it, stir thoroughly for 45 minutes to make a cellulose acetate solution, and seal it for later use;

[0050] 3) Add 2 parts by weight of dimethylolpropionic acid, 3 parts by weight of dihydroxyphenylpropionic acid and 8 parts by weight of N,N-dimethylformamide into a 250ml round bottom flask protected by dry nitrogen, fully Stir for 20 minutes, add 6 parts by weight of toluene diisocyanate, 3 parts by weight of hexamethylene-1,6 diisocyanate and 0.09 parts by weight of dibutyltin dilaurate, stir and react at 100°C for 180 minutes, and distill under reduced pressure Remove the solvent to obtain a polyurethane prepolymer;

[0051] 4) Add the polyurethane prepolymer prepared in step 3) to an organic amine solution prepared by 5 parts by weight of dipropylamine and 48 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com