Ink composition, inkjet recording method, and colored material

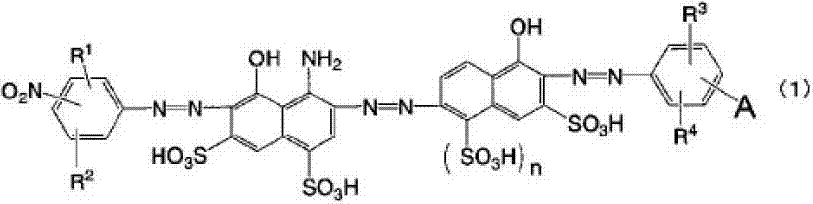

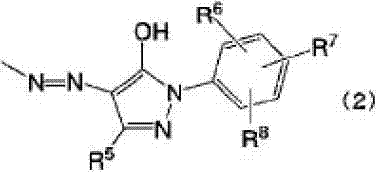

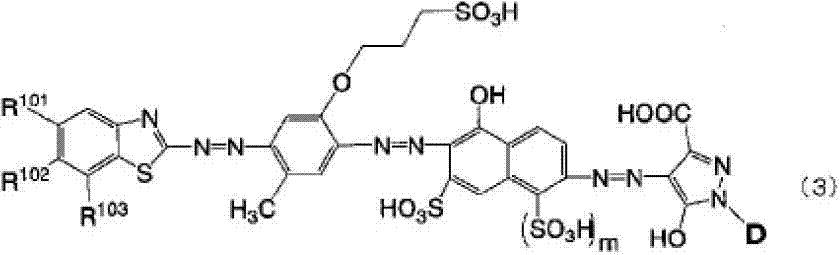

一种油墨组合物、化合物的技术,应用在复制/标记方法、油墨、化学仪器和方法等方向,能够解决不是中性黑色印刷品、无法充分满足图像牢固度的市场要求、未公开高牢固度和发色性油墨组合物等问题,达到优良耐臭氧性、印字浓度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0319] Hereinafter, the present invention will be described more specifically by way of examples, but the present invention is not limited by the following examples.

[0320] In the examples, unless otherwise specified, the places where "parts" and "%" are written are quality standards. In addition, various operations such as synthesis reaction and crystallization are carried out under stirring. In one synthesis reaction, when the desired amount of the target compound is not obtained, the reaction is repeated until the desired amount is obtained.

[0321] In addition, in the following formulas, functional groups such as sulfonic acid group and carboxyl group are represented in the form of free acids for convenience.

[0322] In addition, any of the pH value and the reaction temperature described in the examples represents the measured value in the reaction system.

[0323] In addition, the maximum absorption wavelength (λmax) of the synthesized compound was measured in an aq...

Synthetic example 1

[0328] (Process 1)

[0329] Slowly add 5.0 parts of 2-amino-6-methoxybenzothiazole to 16 parts of 15% oleum at 15-25°C. After addition, it stirred at this temperature for 2 hours, and then dripped into 60 parts of ice water over about 10 minutes. The precipitated crystals were filtered and extracted, and dried to obtain 6.4 parts of a compound represented by the following formula (27).

[0330] 【Chemical 27】

[0331]

[0332] (Process 2)

[0333] Make 3.2 parts of the compound represented by the formula (27) obtained by the above-mentioned procedure (1) suspended in 20 parts of 50% sulfuric acid, and drop 4.7 parts of 40% sulfuric acid in about 10 minutes under stirring at 5-10°C. Nitrosyl sulfuric acid to obtain a diazonium suspension.

[0334] On the other hand, 2.9 parts of the compound represented by the above formula (28), 0.4 parts of sulfamic acid were added to 30 parts of water, and sodium hydroxide was added to adjust the pH to 5.0 to 5.5 to obtain an aqueous sol...

Synthetic example 2

[0366] In the synthesis of the above formula (32), as a raw material, 12.7 parts of 3,5-disulfonic acid aniline can be replaced by using 19.2 parts of 2-aminonaphthalene-4,6,8 trisulfonic acid to obtain the following formula (34 ) was used as a raw material to carry out the above Synthesis Example 1 (Step 5) to obtain a compound (λmax: 607.0 nm) represented by the following formula (35). In addition, this compound is a mixture of the compound represented by No. 32 described in Table 5 and the compound represented by No. 33 described in Table 6.

[0367] 【Chemical 34】

[0368]

[0369] 【Chemical 35】

[0370]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com