Tea-making rubbing machine

A technology for tea essence and tea leaves, which is applied in the field of tea refining and kneading machines, can solve the problems that the tea leaves cannot be swept to the central part of the kneading plate, the palm hair falls off, and the rigidity is poor. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

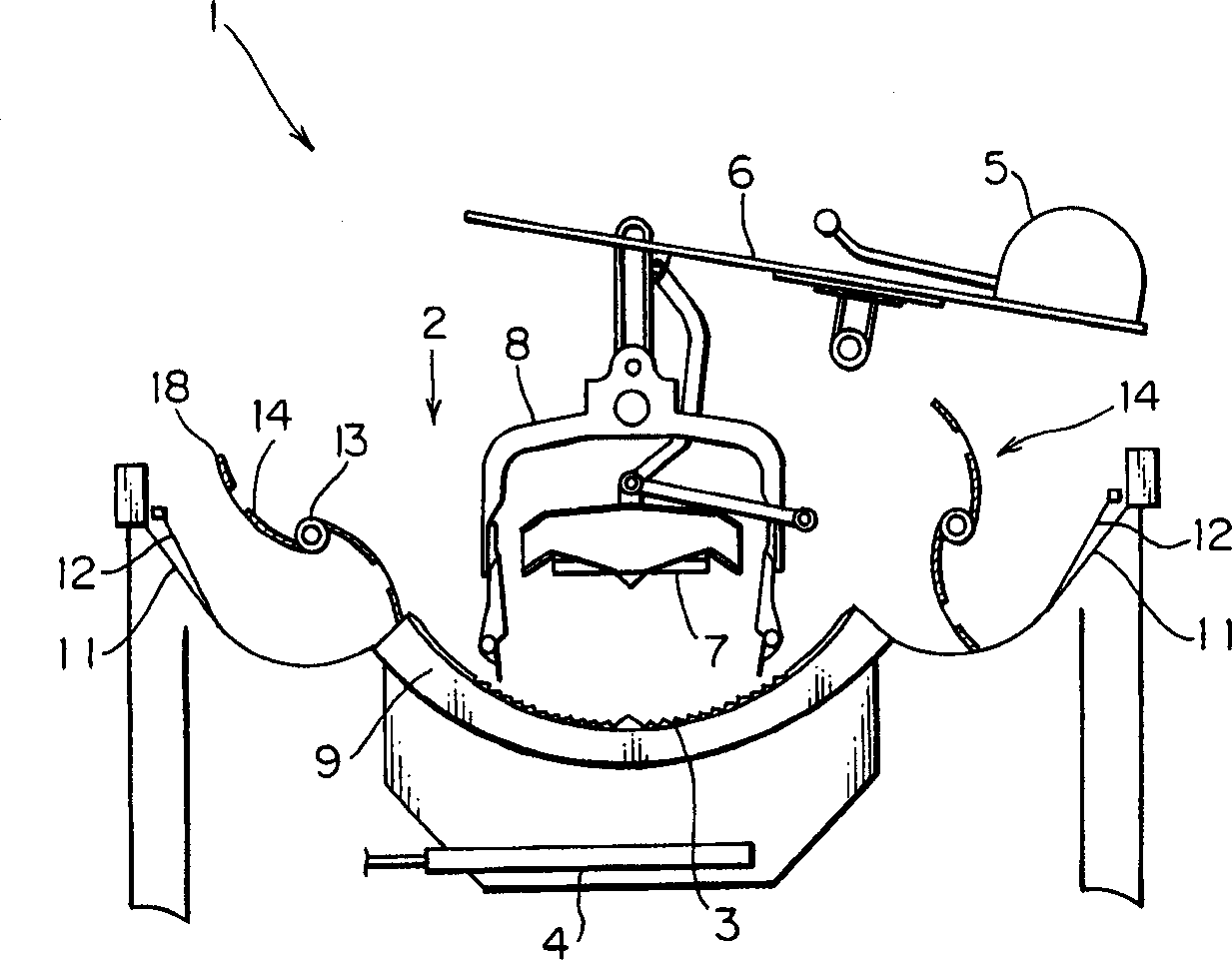

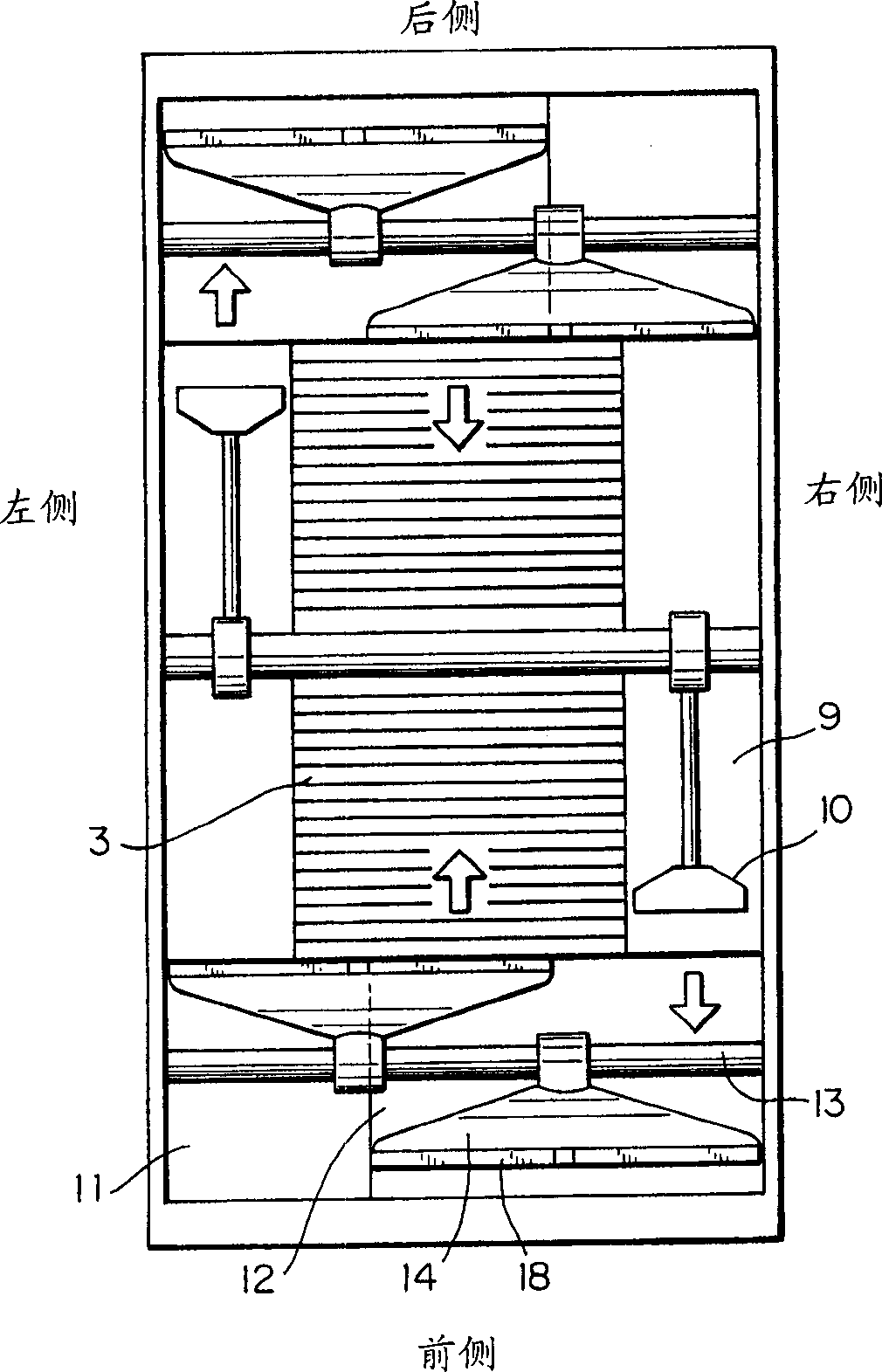

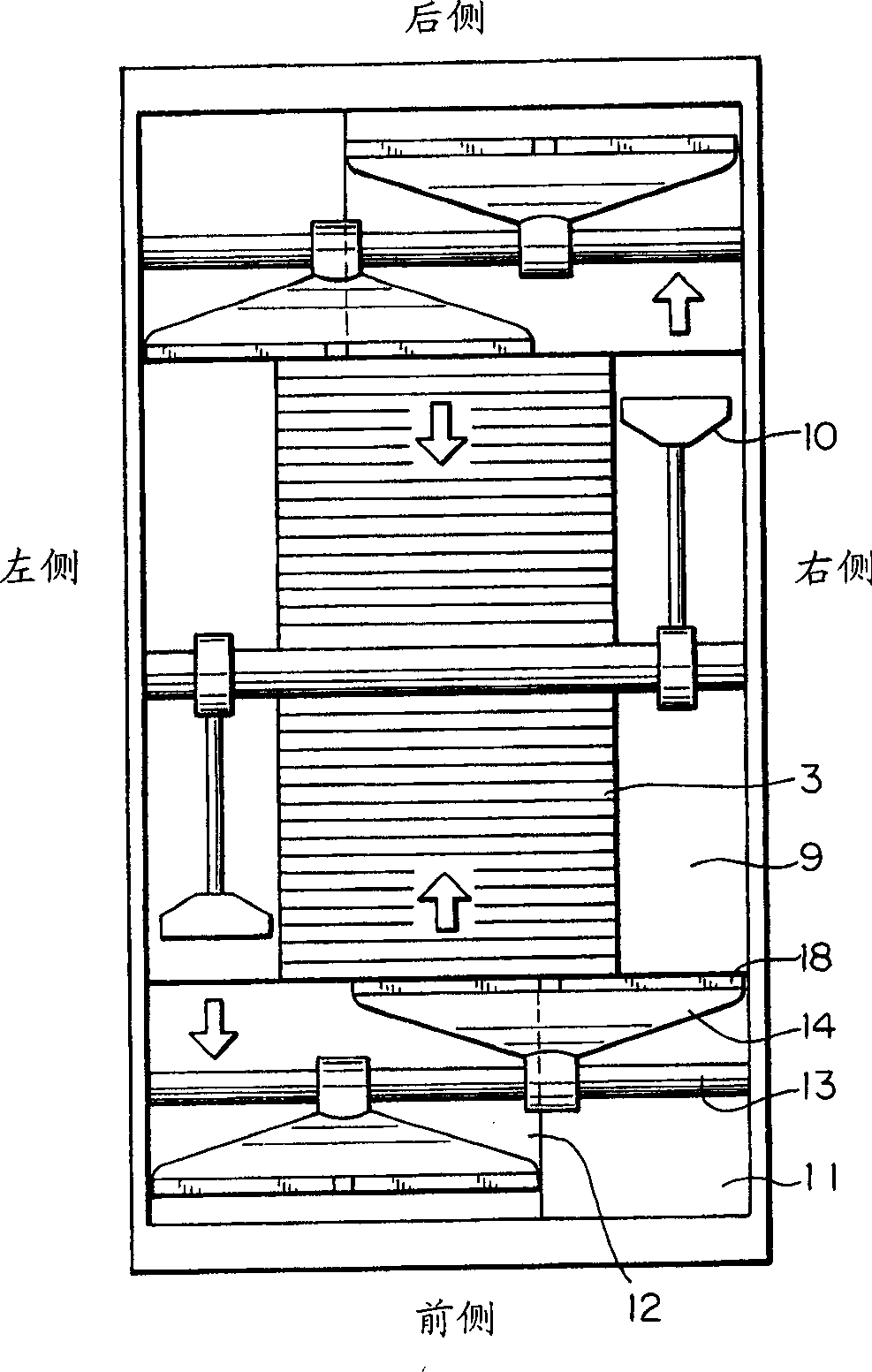

[0020] Hereinafter, embodiments embodying the present invention will be described in detail with reference to the drawings. figure 1 It is a side sectional view of the tea essence kneading machine of the present invention. Tea essence kneading machine 1 such as figure 1 As shown, there is a kneading pan 3 for kneading tea leaves in the kneading kettle 2, and a heating device 4 for heating the kneading pan 3 is provided at the bottom thereof, and a device for kneading and pressing the tea leaves on the kneading pan 3 has a weight 5 and a weight 5. Move the weight guide rail 6 to make the weight 5 move along the weight guide rail 6 to adjust the pressure applied on the kneading plate 7 to provide the pressure required for the tea leaves, so that the kneading hand frame 8 can be shaken back and forth. Knead tea leaves between 7 and kneading plate 3. At this time, a part of the tea leaves that have been kneaded and shaped between the kneading plate 3 and the kneading plate 7 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com