Lintel screen fixed installation complete set of components

A complete set and component technology, applied in the direction of casing/cabinet/drawer parts, supporting machines, mechanical equipment, etc., can solve the problem of unsuitable batch delivery installation, difficult on-site work, and unsuitable for batch production and delivery Installation and other issues, to achieve the effect of simplifying the installation work steps, having safety and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Further illustrate the present invention below in conjunction with accompanying drawing.

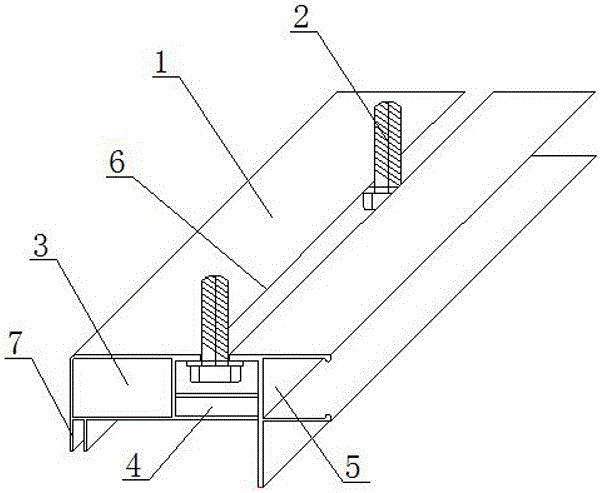

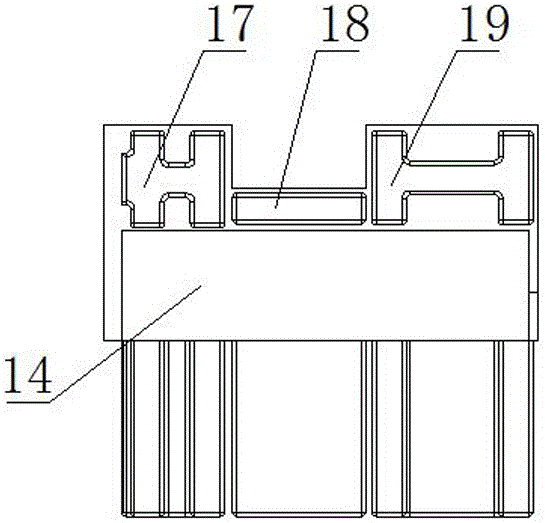

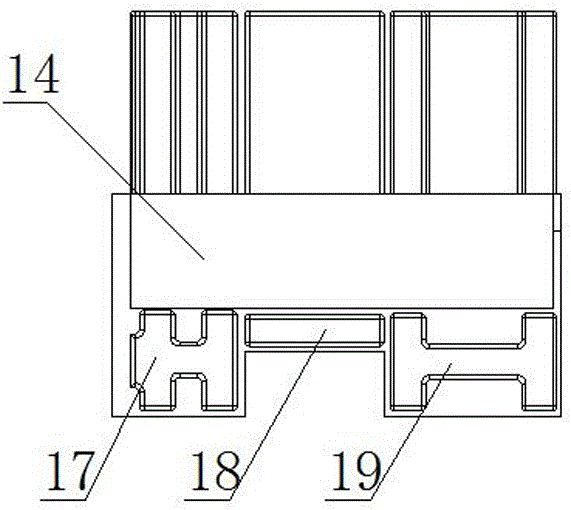

[0040] Such as figure 1As shown, the complete set of components for the fixed installation of the lintel screen is characterized in that it includes a frame body 1 and bolts 2, the frame body 1 is a chute-type hanging point structure, and the frame body 1 is an integrated structure formed by extrusion of a mold , the frame body from left to right is a left part 3, a middle part 4 and a right part 5, the left part 3 is a hollow cuboid structure, and the bottom of the left side of the left part 3 is provided with a card slot 7 ; The middle part 4 is an internal hollow cuboid structure, and a long strip groove 6 is provided along the central axis of the upper frame, and the lower frame is a thickened bottom edge; the right part 5 is a horizontal plate and a vertical plate The connected "F" structure with the opening facing the right; the bolt 2 is installed upside down in the long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com