Large propeller mesopore loam core and casting fastening tool thereof

A propeller and mud core technology, applied in the field of mesopore mud core, can solve the problems affecting processing efficiency, shrinkage cavity defects, shedding, etc., and achieve the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. These examples are only for illustrating the present invention and are not intended to limit the scope of the present invention.

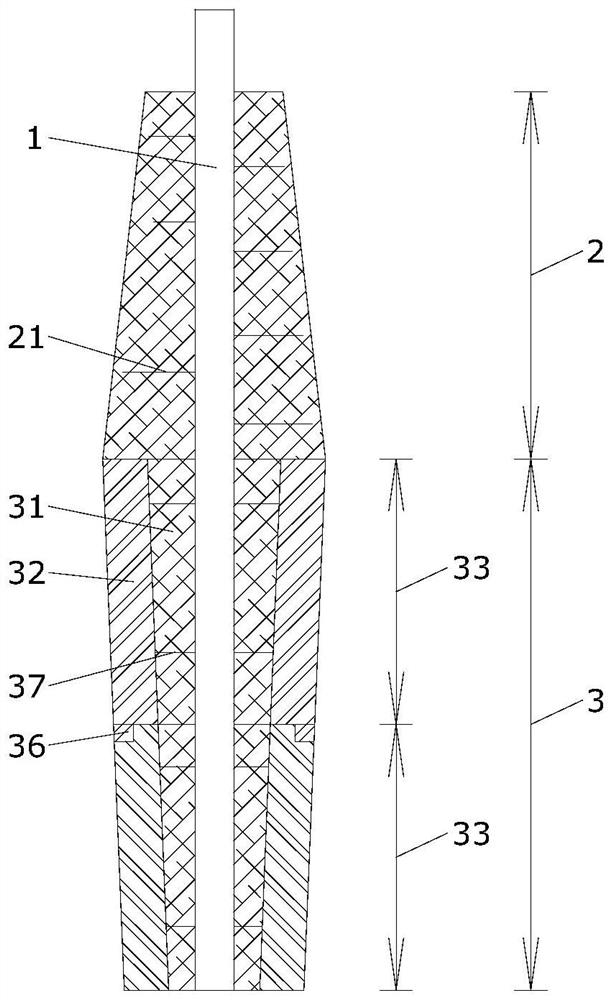

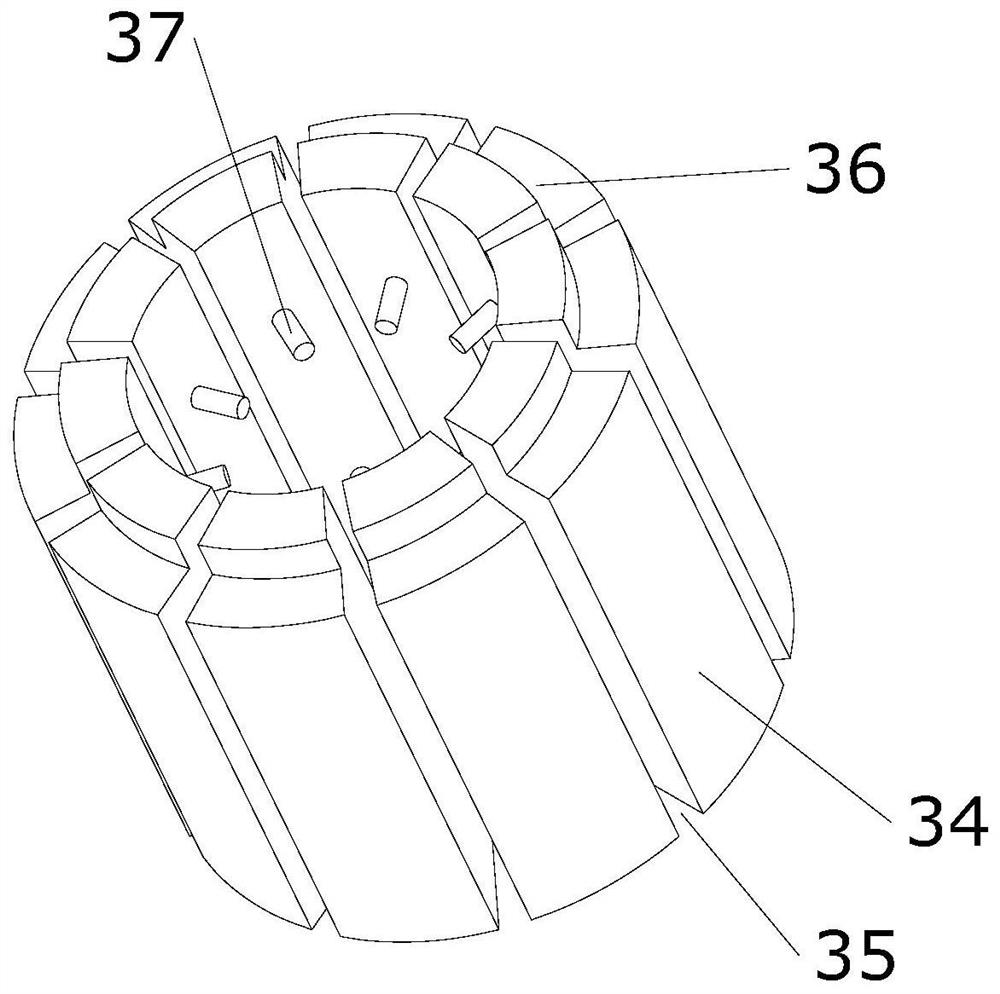

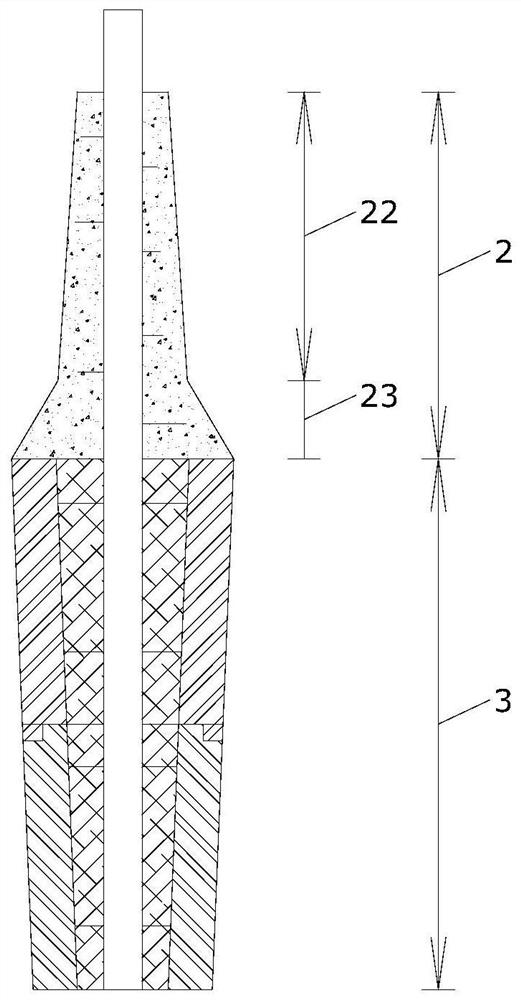

[0030] A large propeller hollow core, as attached figure 1 As shown, it includes a central steel pipe 1 , and a riser section 2 and a body section 3 arranged adjacently up and down on the outer peripheral surface of the central steel pipe 1 . The central steel pipe 1 is a hollow seamless steel pipe. The riser section 2 and the body section 3 are both frustum-shaped structures, and the diameters of the lower bottom surfaces of the two are equal. are adjacent to the bottom surface.

[0031] The central steel pipe 1 in the riser section 2 is provided with a protruding first round steel 21 on its outer wall. The riser section is filled with the first material sand. When filling, the first round steel can be used to st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com