Method for preparing nickel-cobalt lithium aluminate as anode material of lithium ion battery

A nickel-cobalt-aluminate lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as difficult co-precipitation of aluminum ions, and achieve the effect of improving the electrical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

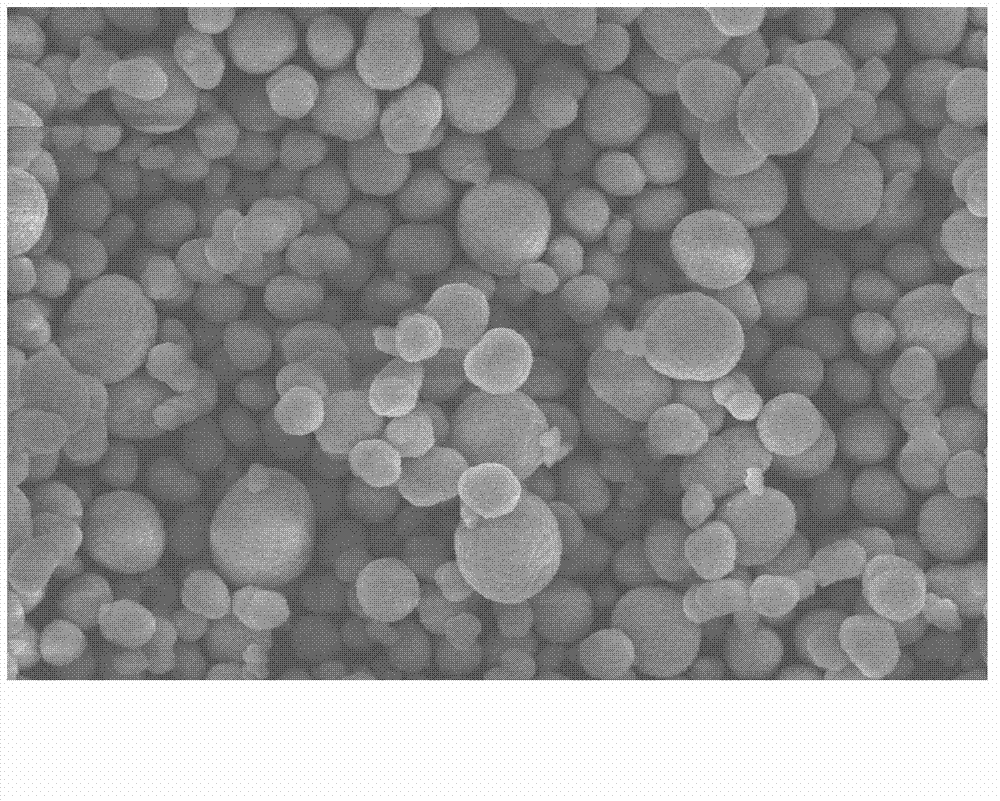

Image

Examples

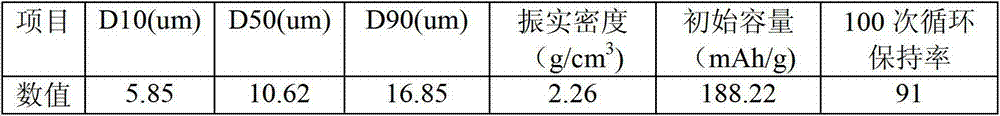

Embodiment 1

[0021] A method for preparing lithium-ion battery cathode material nickel-cobalt-aluminate lithium, comprising the following steps:

[0022] (1) Use nickel sulfate and cobalt sulfate to prepare 200 liters of a solution with a nickel-cobalt molar ratio of 8:1.5 and a total nickel-cobalt molar concentration of 2.0 mol / L;

[0023] (2) Prepare 100 liters of 0.2 mol / L sodium metaaluminate solution with 4.0 mol / L sodium hydroxide solution;

[0024] (3) Put the above-mentioned prepared metal salt solution and sodium metaaluminate solution into the reaction kettle through a certain flow rate, and at the same time add sodium hydroxide as a precipitant and ammonia as a complexing agent, and control the reaction temperature in the reaction kettle to 55 ℃, the concentration of ammonia water is 10.0g / L, and the reaction pH value is 11.50. After 40 hours of reaction, filter the precipitate, wash the precipitate with pure hot water at 80°C, and put the precipitate in a 110°C drying oven to d...

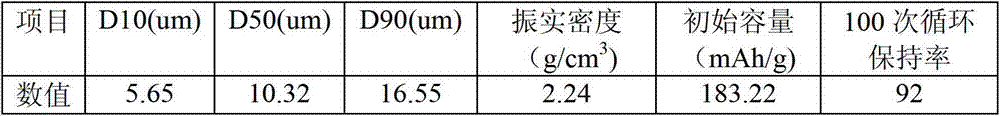

Embodiment 2

[0034] A method for preparing lithium-ion battery cathode material nickel-cobalt-aluminate lithium, comprising the following steps:

[0035] (1) Use nickel sulfate and cobalt sulfate to prepare 200 liters of a solution with a nickel-cobalt molar ratio of 7:2.5 and a total molar concentration of nickel-cobalt-manganese of 2.0 mol / L;

[0036] (2) Prepare 100 liters of 0.2 mol / L sodium metaaluminate solution with 4.0 mol / L sodium hydroxide solution;

[0037] (3) Put the above-mentioned prepared metal salt solution and sodium metaaluminate solution into the reaction kettle through a certain flow rate, and at the same time add sodium hydroxide as a precipitant and ammonia as a complexing agent, and control the reaction temperature in the reaction kettle to 30 ℃, the concentration of ammonia water is 10.0g / L, and the reaction pH value is 9.0. After 200 hours of reaction, filter the precipitate, wash the precipitate with pure hot water at 50°C, and dry the precipitate in a 110°C dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com