Wave spring with nanometer erosion resistant coating

A wave spring and anti-corrosion layer technology, applied in the field of wave springs, can solve the problems of poor dispersion and easy sedimentation of nano-silica, and achieve the effects of high-efficiency peeling, low cost, and excellent coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

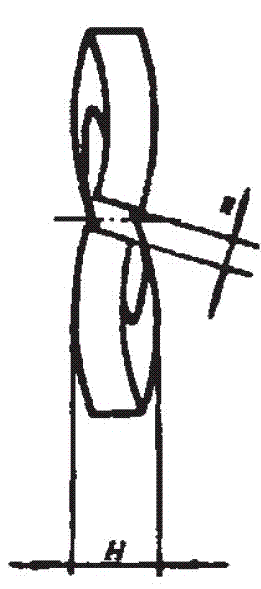

[0030] First of all, through mechanical processing, such as figure 1 The body shown is a wave spring with several sinusoidally formed washer-type springs in the circumferential direction;

[0031] Then, cover a nano anti-corrosion layer on the main structure, and this nano anti-corrosion layer is made by the following steps:

[0032] (1) Add polyether diol with a molecular weight of 3000, castor oil, and organoclay into the reaction kettle for mixing, and stir to raise the temperature. When the temperature rises to 60 °C, add toluene diisocyanate dropwise and finish adding in 40 minutes;

[0033] (2) Then heat and stir at 60 ℃ for 30 minutes, then raise the temperature to 80 ℃ and heat and stir, and take samples to measure the NCO value of the end group;

[0034] (3) When the NCO reaches 3.0%, cool down to 40°C, add styrene to the reaction system, stir for 30 minutes, and vacuum degas at 40°C for 30 minutes to obtain component A—polyurethane prepolymer; the polyether The mas...

Embodiment 2

[0041] First of all, through mechanical processing, such as figure 1 The body shown is a wave spring with several sinusoidally formed washer-type springs in the circumferential direction;

[0042] Then, cover a nano anti-corrosion layer on the main structure, and this nano anti-corrosion layer is made by the following steps:

[0043] (1) Add polyether diol with a molecular weight of 3000, castor oil, and organoclay into the reaction kettle for mixing, and stir to raise the temperature. When the temperature rises to 60 °C, add toluene diisocyanate dropwise and finish adding in 45 minutes;

[0044] (2) Then heat and stir at 60 ℃ for 40 minutes, then raise the temperature to 80 ℃ and heat and stir, and take samples to measure the NCO value of the terminal group;

[0045] (3) When the NCO reaches 3.0%, lower the temperature to 40°C, add styrene to the reaction system, stir for 40 minutes, and vacuum degas at 40°C for 35 minutes to obtain component A—polyurethane prepolymer; the p...

Embodiment 3

[0052] First of all, through mechanical processing, such as figure 1 The body shown is a wave spring with several sinusoidally formed washer-type springs in the circumferential direction;

[0053] Then, cover a nano anti-corrosion layer on the main structure, and this nano anti-corrosion layer is made by the following steps:

[0054] (1) Add polyether diol with a molecular weight of 3000, castor oil, and organoclay into the reaction kettle for mixing, and stir to raise the temperature. When the temperature rises to 60°C, add toluene diisocyanate dropwise and finish adding in 50 minutes;

[0055] (2) Then heat and stir at 60 ℃ for 50 minutes, then raise the temperature to 80 ℃ and heat and stir, and take samples to measure the NCO value of the terminal group;

[0056] (3) When the NCO reaches 3.0%, cool down to 40°C, add styrene to the reaction system, stir for 50 minutes, and vacuum degas at 40°C for 40 minutes to obtain component A—polyurethane prepolymer; the polyether The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com