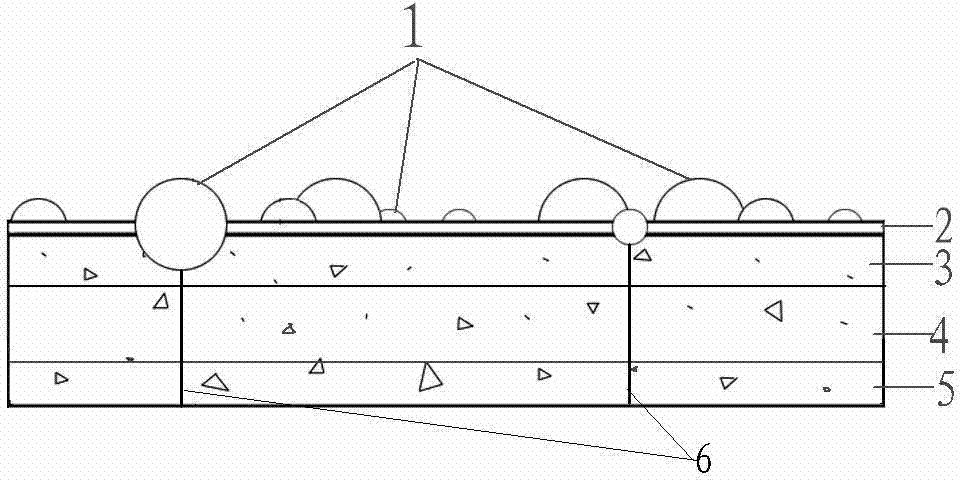

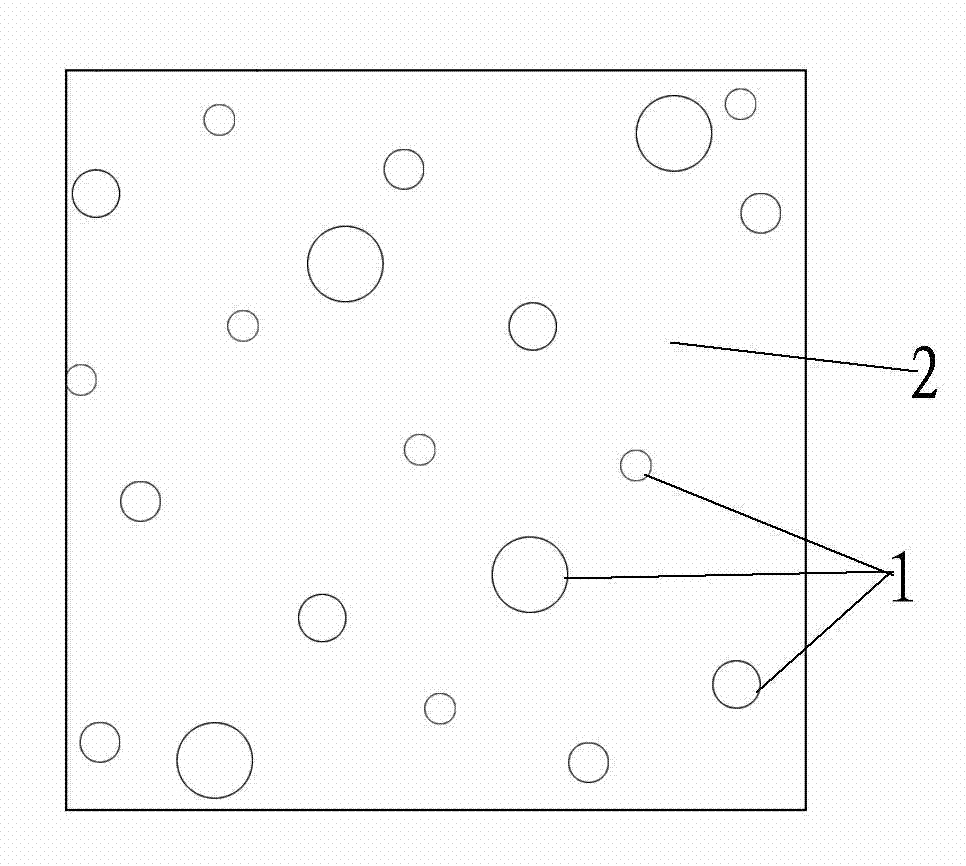

Cement brick with embedded metal balls and manufacture method thereof

A technology of metal beads and cement bricks, applied in the direction of metal layered products, chemical instruments and methods, hydraulic material layered products, etc., can solve problems such as easy cracks, and achieve good water resistance, acid and alkali resistance, and cracks The effect of low probability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of slurry

[0035] Weigh the raw materials needed to prepare the bottom layer 5 according to the following weight ratio, stir evenly, and make slurry A: 25 parts of sulphoaluminate cement, 15 parts of sand, 35 parts of ceramic particles, 15 parts of fly ash, 25 parts Water, 2 parts of glass fiber, 1.0 part of EVA tackifier, 0.4 part of polycarboxylate superplasticizer, 0.03 part of coagulation regulator;

[0036] Weigh the raw materials needed to prepare the transition layer according to the following weight ratio, stir evenly, and make slurry B: 15 parts of aluminophosphate cement, 30 parts of water-soluble epoxy resin, 1.5 parts of glass fiber, 30 parts of sand, 20 parts of water, 0.8 part of EVA tackifier, 0.3 part of polycarboxylate superplasticizer, 0.06 part of coagulation regulator;

[0037] Weigh the raw materials needed to prepare the surface layer 2 according to the following weight ratio, stir evenly, and make slurry C: 45 parts of wa...

Embodiment 2

[0041] (1) Preparation of slurry

[0042] Weigh the raw materials needed to prepare the bottom layer 5 according to the following weight ratio, stir evenly, and make slurry A: 40 parts of sulphoaluminate cement, 15 parts of sand, 35 parts of ceramic particles, 15 parts of fly ash, 25 parts Water, 2 parts of glass fiber, 0.5 part of EVA tackifier, 0.7 part of polycarboxylate superplasticizer, 0.03 part of coagulation regulator;

[0043] Weigh the raw materials needed to prepare the transition layer according to the following weight ratio, stir evenly, and make slurry B: 40 parts of aluminophosphate cement, 10 parts of polyvinyl alcohol, 2.0 parts of glass fiber, 15 parts of sand, 30 parts Water, 0.4 part of EVA tackifier, 0.7 part of polycarboxylate superplasticizer, 0.04 part of coagulation regulator;

[0044] Weigh the raw materials required for the preparation of surface layer 2 according to the following weight ratio, stir evenly, and make slurry C: 55 parts of water-solub...

Embodiment 3

[0048] (1) Preparation of slurry

[0049] Weigh the raw materials needed to prepare the bottom layer 5 according to the following weight ratio, stir them evenly, and make slurry A: 40 parts of sulphoaluminate cement, 10 parts of sand, 20 parts of ceramic particles, 10 parts of fly ash, 15 parts Water, 1.5 parts of glass fiber, 0.4 part of EVA tackifier, 0.6 part of polycarboxylate superplasticizer, 0.02 part of coagulation regulator;

[0050] Weigh the raw materials needed to prepare b-layer 4 according to the following weight ratio, stir evenly, and make slurry B-b: 40 parts of aluminophosphate cement, 10 parts of water-soluble acrylic resin, 2 parts of glass fiber, 30 parts of sand, 30 parts of water, 0.9-.1.8 parts of admixture. 0.3 part of EVA tackifier, 0.6 part of polycarboxylate superplasticizer, 0.04 part of coagulation regulator;

[0051] Weigh the raw materials needed to prepare layer a 3 according to the following weight ratio, stir them evenly, and make slurry B-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com