Abrasion-resisting cement brick

A technology for cement bricks and cement, applied in the field of cement bricks, can solve the problems of large difference in drying shrinkage rate and easy cracks in finished products, and achieve the effects of low cost, low probability of cracks, and good water and acid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] A wear-resistant cement brick is composed of the following ingredients in parts by weight: 25 cement, 60 fly ash, 12 aluminum oxide, 11 magnesium sulfate, 15 chitosan, 22 clay, 11 metal fiber and 18 gypsum.

Embodiment 2

[0012] A wear-resistant cement brick is composed of the following ingredients in parts by weight: 20 parts by weight of cement, 70 parts of fly ash, 10 parts of aluminum oxide, 14 parts of magnesium sulfate, 10 parts of chitosan, 24 parts of clay, 10 parts of metal fiber and 20 parts of gypsum.

Embodiment 3

[0014] A wear-resistant cement brick is composed of the following components in parts by weight: 30 parts by weight of cement, 50 parts of fly ash, 14 parts of aluminum oxide, 8 parts of magnesium sulfate, 20 parts of chitosan, 20 parts of clay, 12 parts of metal fiber and 15 parts of gypsum.

[0015] The production method of the above product is as follows: stirring and mixing each component according to the proportion, adding an appropriate amount of water to make a slurry, injecting into a mold to vibrate, condensing and curing for 3 days, demoulding, and drying.

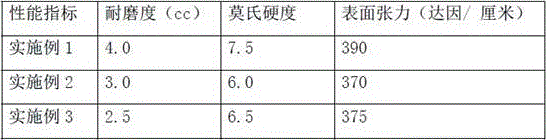

[0016]

[0017] The cement brick prepared by the invention has the functions of high wear resistance and high anti-skid, which reduces the risk of easily slipping and falling when the floor brick is wet. After testing, the product's technical standards meet the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com