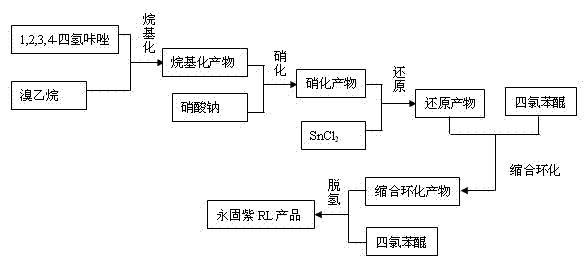

Permanent violet product synthesis and production process

A production process, permanent violet technology, applied in the direction of organic dyes, etc., can solve the problems of reduced actual purity, many by-products, large consumption, etc., to improve yield and purity, increase yield and purity, and reduce reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

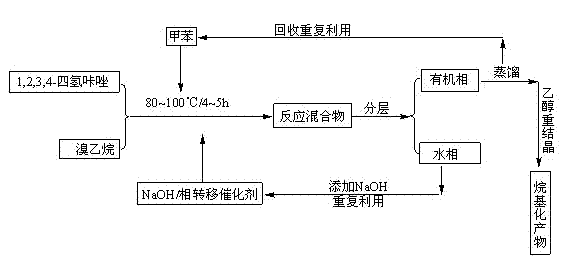

[0042] (1) Alkylation: by figure 2 The synthesis of a kind of permanent violet product of the present invention shown and the process flow sheet of the alkylation step of the production process find out that in the three-necked flask of 1000mL equipped with agitator and condenser tube, add successively 68.4g (400mmol) of 1 , 2,3,4-tetrahydrocarbazole, 160mL of toluene, 400mL of 45% NaOH aqueous solution, 60mL of polyethylene glycol-600, 48g (440mmol) of bromoethane, heated to 100°C for 4h, after the reaction , the reaction solution was layered, and the toluene in the organic phase was evaporated for recycling to obtain the crude product of 9-ethyl-1,2,3,4-tetrahydrocarbazole, which was recrystallized with ethanol to obtain 78.88g (yield=99.1% ) high-purity 9-ethyl-1,2,3,4-tetrahydrocarbazole.

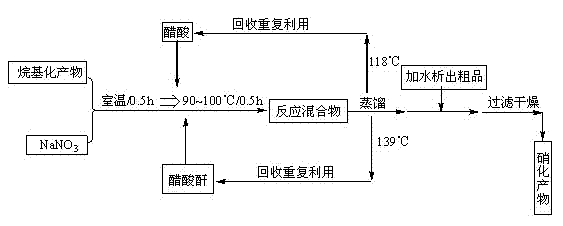

[0043] (2) Nitrification: by image 3 The synthesis of a kind of permanent violet product of the present invention shown and the process flow diagram of the nitration steps of the pr...

Embodiment 2

[0048] The reaction steps of embodiment 2 are the same as embodiment 1.

[0049] (1) Alkylation: Add 68.4g (400mmol) of 1,2,3,4-tetrahydrocarbazole, 160mL of toluene, and 400mL of 50% NaOH to a 1000mL three-necked flask equipped with a stirrer and a condenser Aqueous solution, 60mL of polyethylene glycol-600, 48g (440mmol) of ethyl bromide, heated to 80°C and reacted for 5h. After the reaction, the reaction solution was separated, and the toluene in the organic phase was evaporated for recycling to obtain 9-ethane The crude product of 1,2,3,4-tetrahydrocarbazole was recrystallized from ethanol to obtain 78.56g (yield=98.7%) of high-purity 9-ethyl-1,2,3,4-tetrahydrocarbazole azole.

[0050] (2) Nitration: In a 2000mL three-necked flask equipped with a stirrer and a condenser tube, 34g (400mmol) NaNO 3 Dissolve the solid in 960mL of a mixed solution of acetic acid and acetic anhydride (volume ratio = 1:1), then add 83.58g (420mmol) 9-ethyl-1,2,3,4-tetrahydrocarbazole very slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com