Device and method for preparing composite perfluorinated ion exchange membrane for vanadium battery

A technology of perfluorinated ions and manufacturing equipment, which is applied in the fields of fuel cell parts, renewable fuel cells, sustainable manufacturing/processing, etc. Low production cost, reduced vanadium ion penetration, and less solvent usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

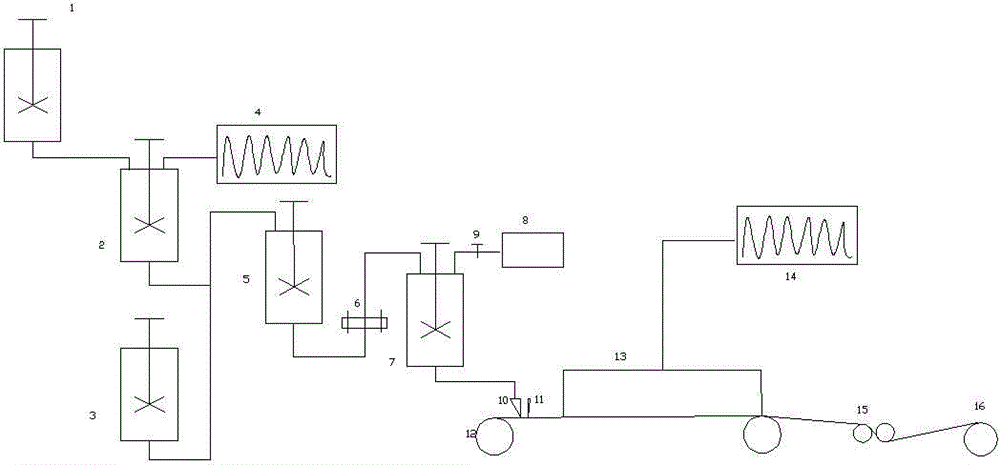

[0031]Embodiment 1: Manufacture composite perfluorinated ion exchange membrane according to the following steps

[0032] (1) Put 10kg of perfluorosulfonic acid ion exchange resin, 20kg of ethanol, 5kg of ethylene glycol, and 5kg of n-propanol into the main material reactor 1, flush nitrogen into the air and close the inlet and outlet valves; start the stirring motor , set the rotation speed at 300 rpm, the temperature at 240°C, heat and stir for 4 hours, observe the gel state of the feed liquid from the viewport of the main material reactor 1, then close the agitator, wait for the feed liquid to cool to 90°C and press it into In the still 2; add 15kg of high boiling point solvent N,N-dimethylformamide into the still 2, start the stirrer of the still 2 to stir, set the temperature to 85°C, stir at a speed of 150 rpm, and stir for 40 minutes Finally, the solvent condensation recoverer 4 is opened to extract the low-boiling point solvent in the distillation still 2. After the ele...

Embodiment 2

[0038] Embodiment 2: manufacture composite perfluorinated ion exchange membrane according to the following steps

[0039] (1) Put 10kg of perfluorosulfonic acid ion exchange resin, 5kg of methanol, 25kg of ethanol, 5kg of ethylene glycol, and 5kg of isopropanol into the main material reactor 1, flush nitrogen into the air, and then close the inlet and outlet valves; Start the stirring motor, set the rotating speed to 300 rpm, and the temperature to 200°C, keep the heat and stir for 10 hours, observe the gel state of the feed liquid from the view port of the main material reactor 1, then close the agitator, and wait for the feed liquid to cool to 90 ℃ into the distillation still 2; 15kg of high boiling point solvent N,N-dimethylformamide was added into the still 2, and the stirrer of the still 2 was started to stir, the temperature was set at 90°C, and the stirring speed was 150 rpm. After stirring for 30 minutes, open the solvent condensation recoverer 4, extract the low-boili...

Embodiment 3

[0045] Embodiment 3: Manufacture composite perfluorinated ion exchange membrane according to the following steps

[0046] (1) Put 10kg of perfluorosulfonic acid ion exchange resin, 5kg of methanol, 40kg of ethanol, 10kg of ethylene glycol, 15kg of n-propanol, 10kg of isopropanol, and 10kg of water into the main material reactor 1, and flush with nitrogen After exhausting the air, close the air inlet and outlet valves; start the stirring motor, set the rotation speed at 300 rpm, the temperature at 280°C, keep stirring for 8 hours, observe the gel state of the material liquid from the main material reactor 1, and then close the stirring After the feed liquid is cooled to 90°C, press it into the distillation still 2; add 10kg of high boiling point solvent N,N-dimethylformamide and 10kg of N,N-dimethylacetamide into the still 2, start the still Stir with the agitator 2, set the temperature to 90°C, and stir at a speed of 150 rpm. After stirring for 30 minutes, open the solvent con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com