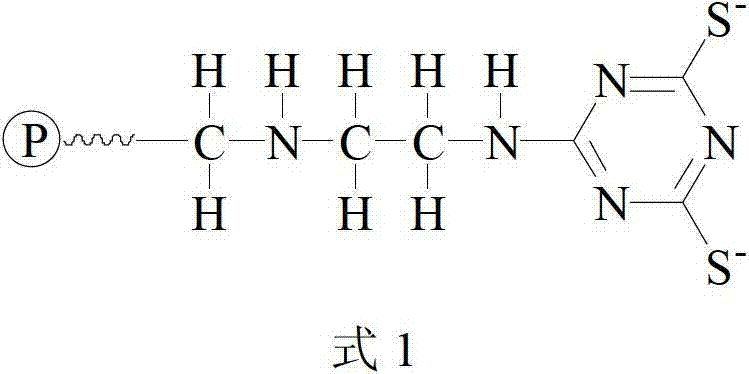

Functional resin containing 4,6-dimercapto-1,3,5-triazine alkali metal salt and preparation method thereof

A technology of alkali metal salt and dimercapto, which is applied in the field of heavy metal industrial wastewater treatment and functional materials, can solve the problems that metal adsorbents cannot be reused, the adsorption capacity of heavy metals is small, and the use cost is high, so as to achieve enhanced synergy, large adsorption capacity, The effect of increased range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

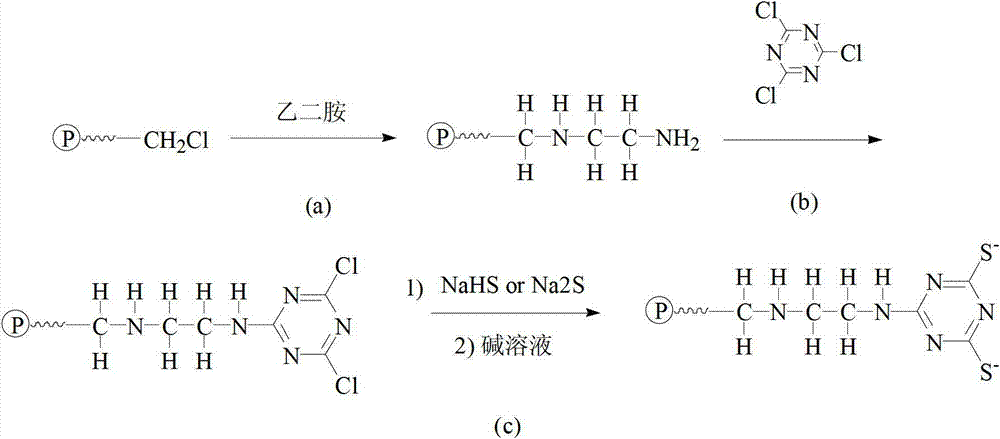

[0038] Add 50.0g of chlorine balls and 100mL of anhydrous toluene into a 250mL three-necked flask, install a stirrer and a reflux condenser, raise the temperature of the oil bath to 90°C while stirring, add 25mL of ethylenediamine dropwise, drop in half an hour After the addition is complete, keep the reaction temperature at 70°C after the dropwise addition. After 8 hours of reaction, cool to room temperature, filter with suction, wash with 150mL 1mol / L NaOH solution three times, wash with water until neutral, then wash with absolute ethanol, and vacuum dry , weighing 56.0g, to obtain grafted ethylenediamine resin, and its weak base exchange capacity was measured to be 1.81mmol / g dry resin, referred to as PE-NH 2 .

[0039] Add 50.0gPE-NH to a 250mL three-necked flask 2 , 100mL anhydrous tetrahydrofuran, 25.0g anhydrous sodium bicarbonate powder, install a stirrer and a reflux condenser, while stirring, cool the oil bath temperature to -2°C, then add anhydrous tetrahydrofuran...

Embodiment 2

[0042] Add 50.0g of chlorine bulbs and 100mL of absolute ethanol to a 250mL three-necked flask, install a stirrer and a reflux condenser, raise the temperature of the oil bath to 60°C while stirring, add 25mL of ethylenediamine dropwise, drop in half an hour After the addition, keep the reaction temperature at 70°C after the dropwise addition. After reacting for 8 hours, cool to room temperature, filter with suction, wash with 150mL 1mol / L NaOH solution three times, wash with water until neutral, then wash with absolute ethanol, and dry in vacuum. Weigh 55.0g to obtain grafted ethylenediamine matrix, measure its weak base exchange capacity of 1.78mmol / g dry resin, referred to as PE-NH2.

[0043] Add 50.0gPE-NH to a 250mL three-necked flask 2 , 100mL of anhydrous acetone, 25g of anhydrous sodium carbonate powder, install a stirrer and a reflux condenser, while stirring, cool the temperature of the oil bath to 0 ° C, dropwise add a mixture of anhydrous tetrahydrofuran and cyanur...

Embodiment 3

[0046] Add 50.0g of chlorine bulbs and 100mL of anhydrous N,N-dimethylformamide into a 250mL three-necked flask, install a stirrer and a reflux condenser, raise the temperature of the oil bath to 90°C while stirring, and add 25mL of Add ethylenediamine dropwise within half an hour. After the dropwise addition, maintain the reaction temperature at 70°C. After reacting for 8 hours, cool to room temperature, filter with suction, wash with 150mL1mol / L NaOH solution three times, wash with water until neutral, and then use After washing with absolute ethanol and vacuum drying, weigh 56.4g to obtain the grafted ethylenediamine matrix, and measure its weak base exchange capacity of 1.84mmol / g dry resin, referred to as PE-NH 2 .

[0047] Add 50.0gPE-NH to a 250mL three-necked flask 2 , 100mL of anhydrous tetrahydrofuran, 25.0g of anhydrous sodium carbonate powder, install a stirrer and a reflux condenser, while stirring, cool the oil bath temperature to 5 ° C, dropwise add a mixture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com