Device and a method for producing biodiesel in a coupling way by treating livestock and poultry breeding wastewater

A technology of livestock and poultry breeding wastewater and biodiesel, which is applied in the field of wastewater treatment, can solve problems such as not being seen, and achieve the effects of simple design, reduced treatment cost, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

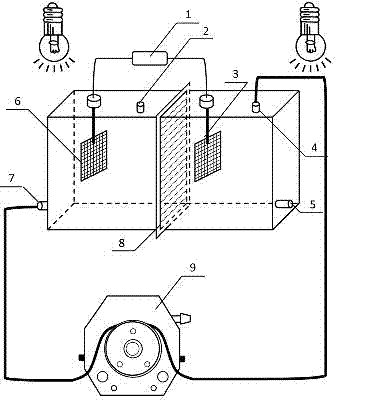

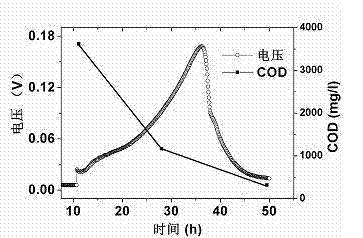

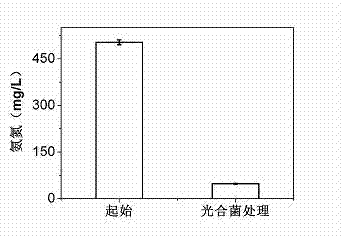

[0028] Embodiment 1: Inject livestock and poultry breeding wastewater into the anode chamber through the anode sample inlet, inoculate photosynthetic bacteria in a ratio of 2%-20%, after the inoculation, the airtight anode chamber is isolated from the air, and the anode chamber is used as a fluorescent lamp, an incandescent lamp, an LED lamp or the sun. Light source, the light intensity is controlled at 2000-10000 lux, the temperature is controlled at 23-35°C, and the cathode microalgae produces oxygen through photosynthesis as the electron acceptor. After 50 hours of system treatment, the COD removal rate of livestock and poultry wastewater reaches 94.4%. Under the condition of 1000 Ω, the voltage can reach up to 160 mv ( figure 2 ), the removal rate of ammonia nitrogen from livestock and poultry wastewater was 90.4% ( image 3 ).

Embodiment 2

[0029] Embodiment 2: the anode water outlet is connected with the cathode water inlet, and the livestock and poultry breeding wastewater treated by the anode is jumped to the cathode chamber with a pump, and the microalgae cultivated to the logarithmic growth phase are respectively inoculated in the inoculation amount of 2-20% In the cathode chamber liquid, the concentration of microalgae is about 0.1-0.5 g / L, and the culture temperature is 23°C-35°C. Inject livestock and poultry breeding wastewater into the anode chamber through the anode sample port, inoculate photosynthetic bacteria at a ratio of 2%-20%, use fluorescent lamps, incandescent lamps, LED lamps or the sun as the light source, control the light intensity at 2000-10000 lux, and cultivate the anode water After 13 days of microalgae, the removal rate of ammonia nitrogen was 86.8% ( Figure 4 ) total phosphorus and total nitrogen removal rates were 90.4% and 96.7% ( Figure 5 , Image 6 ), the microalgae cell densi...

Embodiment 3

[0030] Example 3: The oil content of the microalgae in the cathode chamber was 28.2% after 13 days of culture, slightly lower than the oil content of the microalgae in the BG11 culture medium at the same time ( Figure 8 ), the specific determination method is to take 40 mL of algae liquid, centrifuge and concentrate to 0. 8 mL, add 2 mL of methanol and 1 mL of chloroform to it, and mix thoroughly for 2 min. Then add 1 mL of chloroform, mix for 30 s; add 1 mL of water, mix for 30 s, centrifuge at 4000 rpm for 10 min, absorb the entire chloroform layer (bottom layer), and blow with nitrogen at 60°C. Place the blown-dried centrifuge tube at room temperature and dry to constant weight, weigh the mass change before and after the centrifuge tube, that is, the weight of the oil, and the ratio of the weight of the oil to the dry weight of the extracted oil algae can be used to obtain the oil content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com