Method for preparing lamellar aragonite calcium carbonate powder from shell under hydrothermal condition

A technology of calcium carbonate powder and shell powder, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of difficulty in removing shell insoluble protein, inability to obtain aragonite-structured calcium carbonate, and inability to obtain high-purity calcium carbonate micropowder, etc. Achieve significant economic and social value, improve hydrolysis reaction rate, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

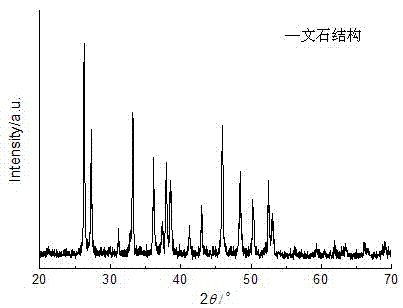

[0022] Take 5 grams of 150-mesh clam shell powder, add it to 60 ml of tartaric acid aqueous solution with a concentration of 0.1 mol / liter, mix well, pour it into a 100 ml tetrafluoroethylene-lined autoclave, and treat it at 190°C for 6 hours , and then separate the precipitate, wash with water, and dry to obtain calcium carbonate micropowder. The X-ray structure analysis of clam shell powder after hydrothermal treatment shows that the powder is calcium carbonate with aragonite structure, such as figure 1 as shown,

Embodiment 2

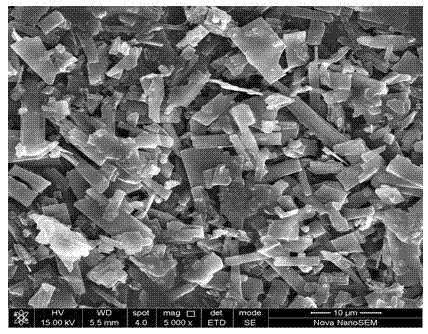

[0024] Take 10 grams of 150-mesh mussel shell powder, add it to 60 ml of citric acid aqueous solution with a concentration of 0.2 mol / L, mix well, pour it into a 100 ml tetrafluoroethylene-lined autoclave, and treat it at 160°C for 6 hours , and then separate the precipitate, wash with water, and dry to obtain calcium carbonate micropowder. SEM observation of hydrothermally treated mussel shell powder, such as figure 2 Show. It can be seen from the photos that the powder particles are typical strip-shaped aragonite, which is the same shape as shell aragonite, indicating that the flaky aragonite structure is still retained after hydrothermal treatment in citric acid solution, and the particle size of the powder is between Between 1 and 10 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com