Method for pre-stretch bending of metal thick slab and numerical control machining forming of high-rib wallboard with curvature

A technology for processing and forming thick slabs, which is used in the pre-stretching and bending of metal thick slabs and the CNC machining and forming of high-curvature wall panels, metal forming internal stress control and CNC machining. It can solve the problem of strong dependence on operator experience. , large residual stress, low production efficiency, etc., to ensure product quality and process stability, reduce workload, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

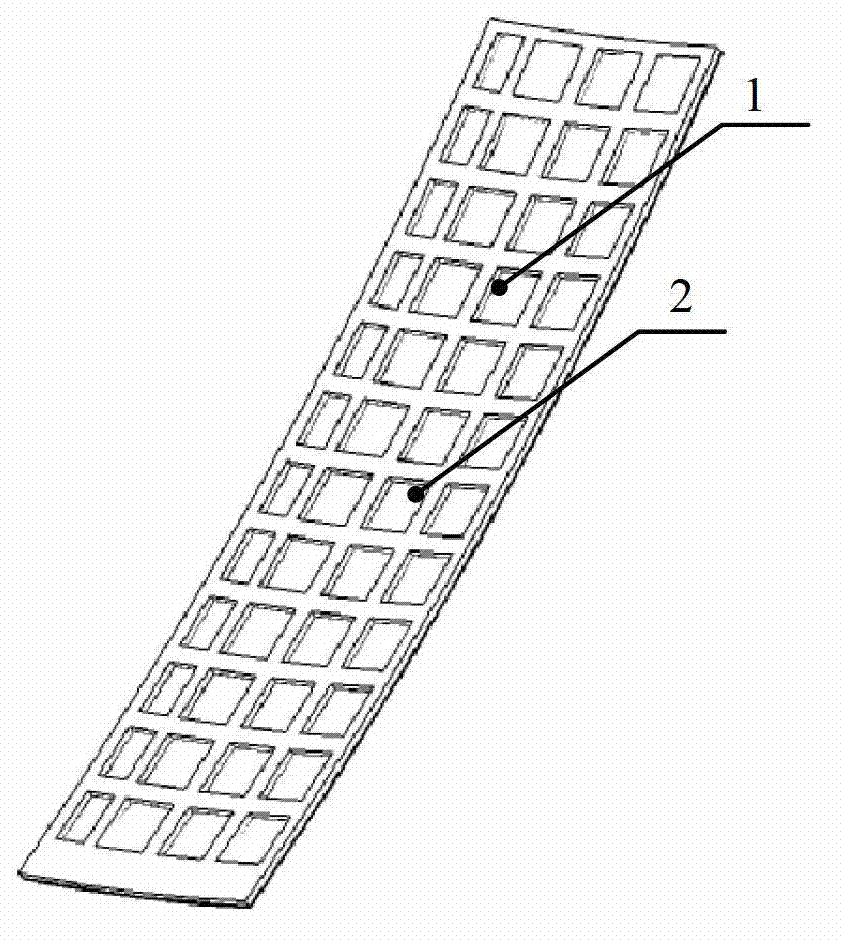

[0011] refer to Figure 1-2 , implement pre-stretch bending and numerical control machining forming on the metal thick plate blank, the main forming process of the method includes pre-stretching bending of the metal thick plate blank and precise numerical control machining forming of the curved high-rib wall plate. The specific implementation process: first obtain the alloy slab after rolling, forging and heat treatment. Then fix the alloy slab on the chuck of a CNC stretch bending machine with a capacity of more than 100 tons, and pre-bend the alloy slab with an elongation rate of 1-10% according to the requirements, so that the shape is similar to that of the finished wall plate, and the residual stress A pre-stretched slab less than or equal to the measured value of an existing pre-stretched slab. Finally, CNC machining is carried out on the pre-stretch bending slab, and the machining environment, machining process and machining parameters are controlled. Finally, the dime...

Embodiment 2

[0013] refer to figure 1 , first obtain the alloy slab after rolling, forging and heat treatment. Then the alloy slab is fixed on the chuck of a numerically controlled stretch bending machine of more than 100 tons; the alloy slab is subjected to a combination of stretching and bending with an elongation of 1-10% according to the shape of the wall plate and the distribution of residual stress Pre-bending deformation method. Finally, a pre-stretched bent slab whose shape is similar to that of the finished product and whose residual stress is less than or equal to the actual measured value of the existing pre-stretched slab is obtained.

Embodiment 3

[0015] refer to figure 2 , first obtain the alloy slab after stress relief. Then use high-precision CNC machining machine tools to implement CNC machining on the slab through rough machining, semi-finishing, and finishing processes. Ambient temperature for controlling processing: -30°C to +50°C, spindle speed: 500-20000r / min, feed speed: 1-120m / min, feed angle: 0.1-90°, and according to the tool material and shape size Properly select the tool path, cutting depth and width and the clamping posture of the blank based on factors such as the processed material and shape size, the residual stress distribution in the processed blank, and the process of the processed blank. Finally, a wall panel with a dimensional accuracy of 0.01-5mm, a smooth outer surface, and a design theoretical shape is obtained. The outer surface of the wallboard is a curved surface, and the inner surface is composed of ribs 1 and grooves 2, which is an integral wallboard with curvature and high ribs. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com