Ulipristal acetate medicine composition

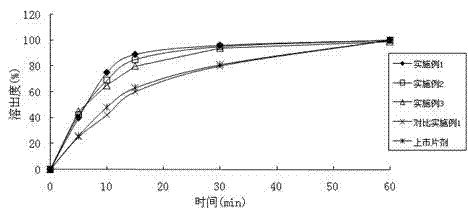

A technology of unilast acetate and a composition, applied in the field of pharmaceutical preparations, can solve problems such as poor dissolution, and achieve the effects of improving solubility or dissolution, good stability, and excellent pharmaceutical technical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

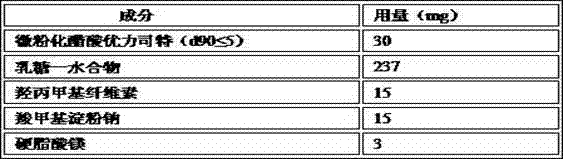

Embodiment 1

[0042] The following formulation was used for the preparation of tablets each containing 30 mg of micronized uliplast acetate.

[0043]

[0044] Manufacturing process: Tablets were prepared using standard wet granulation procedures. Sieve and mix micronized uliplast acetate (d90≤5), lactose monohydrate, and hypromellose evenly; use a high-efficiency wet mixing granulator or any other suitable wet granulator, and use purified water The mixed material is granulated; the wet granules are dried in a fluidized bed or an oven; after drying, the granules are sized; the sodium carboxymethyl starch and magnesium stearate are sieved and mixed with the dried granules; The final granules are compressed into tablets.

Embodiment 2

[0046] The following formulation was used for the preparation of tablets containing 10 mg of micronized uliplast acetate each.

[0047]

[0048]

[0049] Manufacturing process: Tablets were prepared using standard direct compression procedures. Sieve and mix micronized uliplast acetate (d90≤5), microcrystalline cellulose, hydroxypropylmethyl cellulose, and sodium carboxymethyl starch; Mix well; use a tablet machine to compress the mixture into tablets.

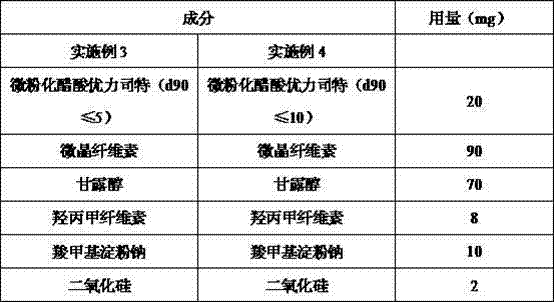

Embodiment 3-4

[0051] The following formulation is used for the preparation of hard capsules containing 20 mg of micronized uliplast acetate per tablet.

[0052]

[0053]

[0054]Preparation process: Standard wet granulation steps are used to prepare capsule granules. Sieve and mix micronized uliplast acetate (d90≤5 or d90≤10), microcrystalline cellulose, mannitol, hypromellose, and sodium carboxymethyl starch; use a high-efficiency wet mixing granulator or Any other suitable wet granulator, use purified water to granulate the mixed material; wet granules are dried in a fluidized bed or an oven; granulated after drying; sieved and mixed with the dried granules evenly; The capsule filling machine makes the mixed granules into hard capsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com