Method for preparing nanofibre membrane

A nanofiber membrane, chitosan technology, applied in fiber treatment, spinning solution preparation, medical science and other directions, can solve problems such as no reports, achieve good biocompatibility and reduce platelet aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

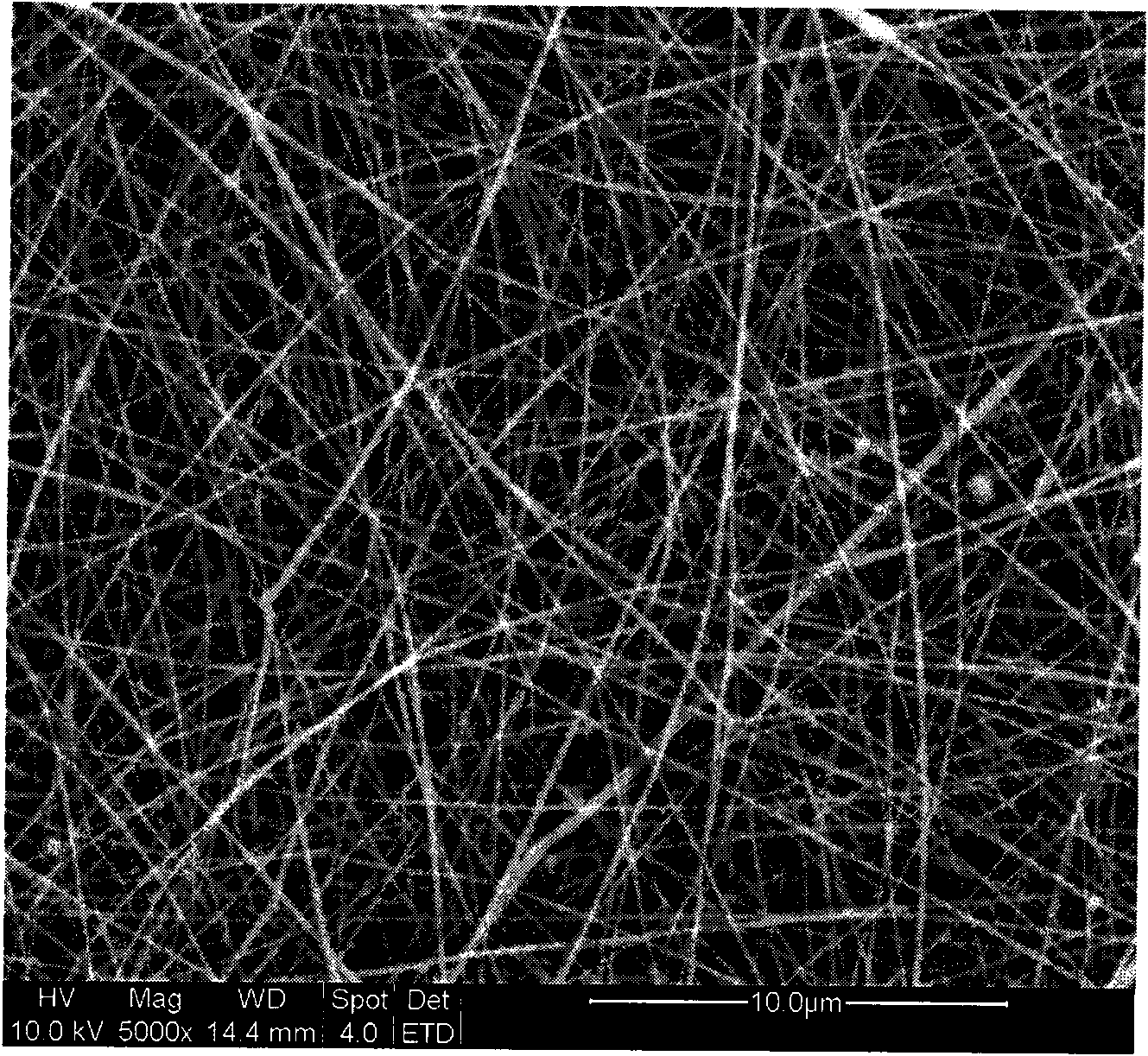

Image

Examples

Embodiment 1

[0026] (1) preparation mass concentration is the acetic acid aqueous solution of 3%, with relative molecular weight being 300,000, the chitosan that deacetylation degree is 85% is dissolved in the acetic acid aqueous solution, is configured into the chitosan acetic acid that mass concentration is 60g / L solution.

[0027] (2) Dissolve curcumin in absolute ethanol, stir and dissolve, and prepare a curcumin absolute ethanol solution with a curcumin concentration of 20 g / l.

[0028] (3) Chitosan acetic acid solution and curcumin absolute ethanol solution were mixed at a volume ratio of 5:1 to prepare an electrospinning solution with a concentration of 5% (w / v).

[0029] (4) The prepared spinning solution was injected into the syringe of the electrospinning device, and the inner diameter of the nozzle was 0.7 mm. The electrospinning process conditions are as follows: the voltage is 15kV, the flow rate is 0.05ml / h, and the receiving distance is 15cm.

[0030] (5) Adopting a drum c...

Embodiment 2

[0033] (1) preparation mass concentration is the acetic acid aqueous solution of 3%, with relative molecular weight being 200,000, the chitosan that deacetylation degree is 95% is dissolved in the acetic acid aqueous solution, is configured into the chitosan acetic acid that mass concentration is 50g / l solution.

[0034] (2) Dissolve curcumin in absolute ethanol, stir and dissolve, and prepare curcumin absolute ethanol solution with a curcumin concentration of 25 g / l.

[0035] (3) Chitosan acetic acid solution and curcumin absolute ethanol solution were mixed at a volume ratio of 6:1 to prepare an electrospinning solution with a concentration of 6% (w / v).

[0036] (4) The prepared spinning solution was injected into the syringe of the electrospinning device, and the inner diameter of the nozzle was 0.8 mm. The electrospinning process conditions are as follows: the voltage is 18kV, the flow rate is 0.08ml / h, and the receiving distance is 17cm.

[0037] (5) Using a flat plate ...

Embodiment 3

[0040] (1) preparation mass concentration is the acetic acid aqueous solution of 4%, with relative molecular weight being 400,000, the chitosan that deacetylation degree is 80% is dissolved in the acetic acid aqueous solution, is configured into the chitosan acetic acid that mass concentration is 55g / l solution.

[0041] (2) Dissolving curcumin in absolute ethanol, stirring and dissolving, and preparing a curcumin absolute ethanol solution with a curcumin concentration of 30 g / l.

[0042] (3) Chitosan acetic acid solution and curcumin absolute ethanol solution were mixed at a volume ratio of 8:1 to prepare an electrospinning solution with a concentration of 6% (w / v).

[0043] (4) The prepared spinning solution was injected into the syringe of the electrospinning device, and the inner diameter of the nozzle was 0.9mm. The electrospinning process conditions are as follows: the voltage is 18kV, the flow rate is 0.08mL / h, and the receiving distance is 18cm.

[0044] (5) Using a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com