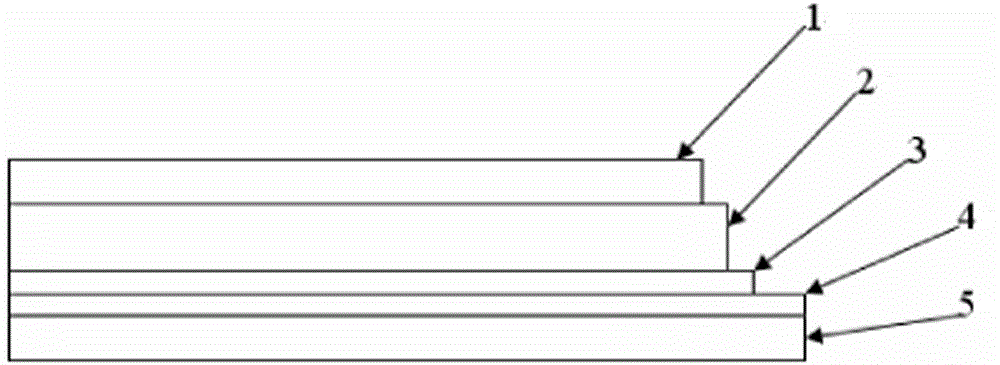

Preparation method of large-area organic polymer solar cells

A solar cell and polymer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to meet organic solar cells, small size, etc., and achieve the effect of saving production time, realizing industrial production, and ensuring conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

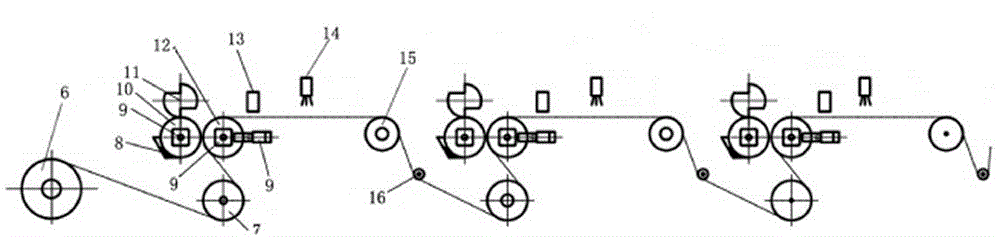

[0039] Firstly, PEDOT:PSS solution, P3HT:PC prepared in advance and mixed uniformly 61 BM solution and conductive silver ink were poured into three troughs in sequence. The preparation parameters of these three solutions are: PEDOT: the mass volume percentage of solute and solvent in PSS solution is 1%; P3HT: PC 61 P3HT and PC in BM solution 61 The ratio of BM is the same, the solvent is chlorobenzene, and the mass volume percentage of solute and solvent is 2.5%; the mass volume percentage of solute and solvent in conductive silver ink is 2%.

[0040] Place the polyethylene terephthalate (PET) flexible substrate roll with etched ITO electrodes on the damping unwinding mechanism 1, accurately locate the starting position, and adjust the synchronous mechanisms so that the three-layer coating device The starting position is the same. The running speed of the coating device was set to 0.1 m / s, and the speeds of the three coating processes were the same.

[0041] The first coat...

Embodiment 2

[0046] Firstly, PEDOT:PSS solution, PCDTBT:PC prepared in advance and mixed uniformly 71 BM solution and conductive silver ink were poured into three troughs in sequence. The preparation parameters of these three solutions are: PEDOT: the mass volume percentage of solute and solvent in PSS solution is 1%; PCDTBT: PC 71 PCDTBT and PC in BM solution 71 The ratio of BM is 1:4, the solvent is a mixed solvent formed by chloroform and chlorobenzene in the same proportion, the mass volume percentage of solute and solvent is 2%; the mass volume percentage of solute and solvent in conductive silver ink is 2%.

[0047] Place the polyethylene terephthalate (PET) flexible substrate roll with etched ITO electrodes on the damping unwinding mechanism 1, accurately locate the starting position, and adjust the synchronous mechanisms so that the three-layer coating device The starting position is the same. The running speed of the coating device was set to 0.1 m / s, and the speeds of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com