Treatment process for tuber mustard waste water

A treatment process and technology of mustard wastewater, applied in high COD, high ammonia nitrogen, high phosphorus mustard wastewater, mustard production wastewater treatment process, high salt fields, can solve the problem of difficult to reach the first-level discharge standard, and achieve high denitrification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

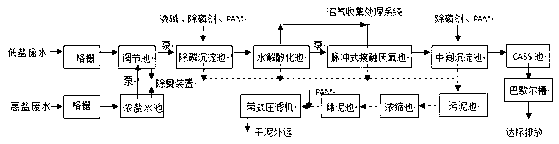

[0021] Such as figure 1 Shown, sewage treatment process of the present invention is as follows:

[0022] The low-salt wastewater passes through the grid through the sewage pipeline to the regulating tank, and the high-salt wastewater enters the concentrated brine tank through the sewage pipeline through the grid for storage; the dilute brine and concentrated brine are transported to the phosphorus removal sedimentation tank after the water volume is adjusted and the water quality is adjusted in the regulating tank. , and then go to the hydrolytic acidification tank for hydrolytic acidification, and then lift the effluent from the hydrolytic acidification tank to the pulse contact anaerobic tank to enter the anaerobic methanation stage, and the anaerobic effluent enters the intermediate sedimentation tank to add flocculant for secondary phosphorus removal, CASS The anoxic-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com