Desulfurization, denitrification and defluorination treating fluid and application thereof

A technology for desulfurization, denitrification, and liquid treatment, applied in separation methods, dispersion particle separation, chemical instruments and methods, etc., can solve problems such as troublesome processing, low operating costs, strong absorption capacity of sodium-alkali method, etc., and achieve low cost and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

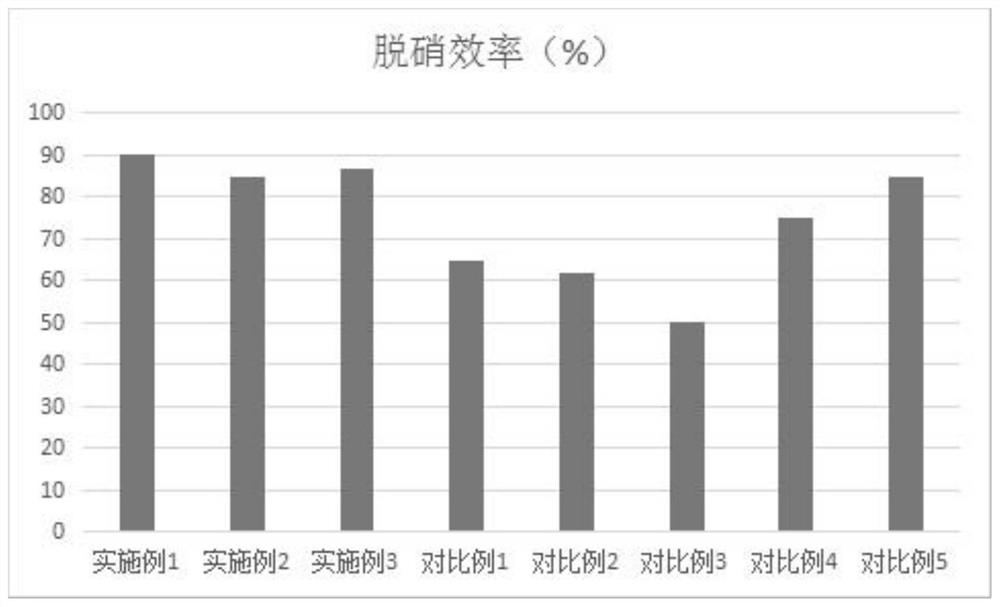

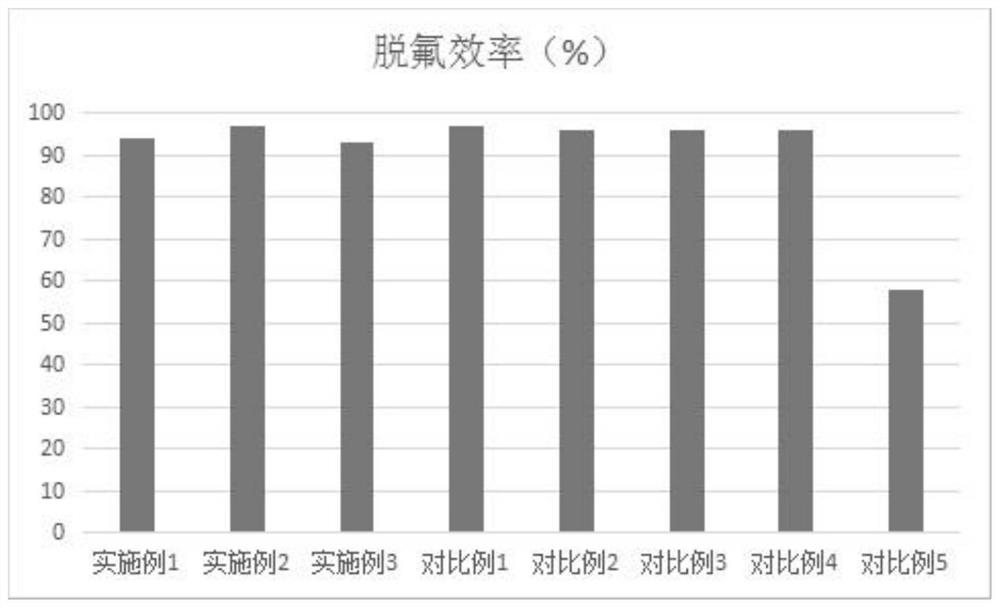

Embodiment 1

[0020] A desulfurization, denitrification and defluorination treatment liquid, comprising the following molar concentration raw materials: NaClO concentration 3mmol / L, H 2 o 2 Concentration 10mmol / L, NaOH concentration 7mmol / L, NaOH 2 CO 3 The concentration is 3mmol / L, and the initial pH value of the treatment solution is about 12. Prepare the desulfurization, denitrification and defluorination treatment solution of the above concentration, and spray it from the top of the desulfurization, denitrification and defluorination tower with a spray pump. The test results of the treated waste gas show that the desulfurization efficiency is 95%, the denitrification efficiency is 90%, and the defluorination efficiency is 94%.

Embodiment 2

[0022] A desulfurization, denitrification and defluorination treatment liquid, including the following molar concentration raw materials: NaClO concentration 7mmol / L, H 2 o 2 Concentration 6mmol / L, NaOH concentration 5mmol / L, NaOH 2 CO 3 The concentration is 5mmol / L, and the initial pH value of the treatment solution is about 10. Prepare the desulfurization, denitrification and defluorination treatment liquid of the above concentration, and spray it from the top of the desulfurization, denitrification and defluorination tower with a spray pump. The test results of the treated waste gas show that the desulfurization efficiency is 92%, the denitrification efficiency is 85%, and the defluorination efficiency is 97%.

Embodiment 3

[0024] A desulfurization, denitrification and defluorination treatment liquid, including the following molar concentration raw materials: NaClO concentration 7mmol / L, H 2 o 2 Concentration 6mmol / L, NaOH concentration 5mmol / L, NaOH 2 CO 3 The concentration is 5mmol / L, and the initial pH value of the treatment solution is about 10. Prepare the desulfurization, denitrification and defluorination treatment liquid of the above concentration, and spray it from the top of the desulfurization, denitrification and defluorination tower with a spray pump. The test results of the treated waste gas show that the desulfurization efficiency is 92%, the denitrification efficiency is 85%, and the defluorination efficiency is 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com