Selective catalytic reduction (SCR) flue gas denitrification catalyst and preparation method thereof

A denitration catalyst and catalyst technology are applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., which can solve the problems of short service life of catalysts, high cost of raw materials, complicated process, etc., and reduce the cost of raw materials. , the effect of improving catalytic activity and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

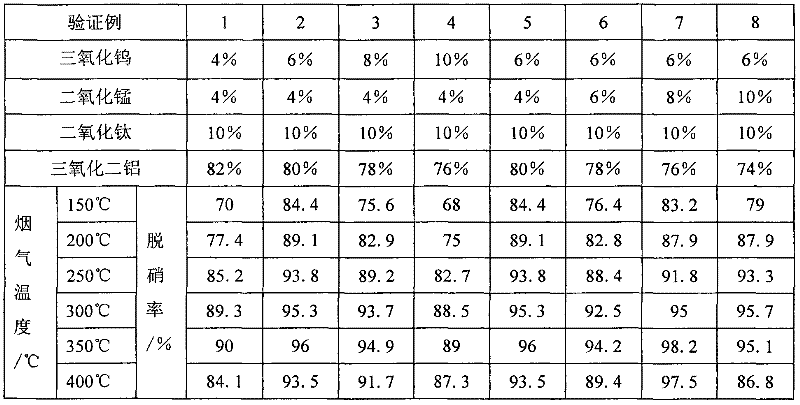

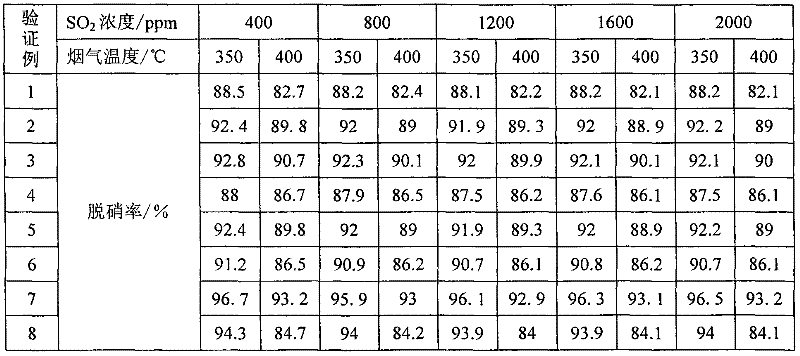

[0019] One, a kind of SCR flue gas denitration catalyst, comprises carrier TiO in this denitration catalyst component 2 , loaded on TiO 2 The main active components and cocatalysts on WO 3 , and the structural support material that binds the denitration catalyst into particles, wherein, TiO 2 It exists in the form of anatase. In the present invention, the main active component is MnO 2 , the structural support material is Al 2 o 3 Gel; the mass percent content of each component in the denitration catalyst is: 10% TiO 2 , 4% to 10% MnO 2 , 4% to 10% of WO 3 , the balance being Al 2 o 3 Gel; the particle size of the denitration catalyst particles is 0.8-1.2 cm.

[0020] Two, a preparation method of SCR flue gas denitrification catalyst, this flue gas denitrification catalyst is the SCR flue gas denitrification catalyst described in the above-mentioned specific embodiment one, and the method comprises the following steps:

[0021] (1) Preparation of active component so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com