Method for directly synthesizing lead sulfide cube nano particle film

A nanoparticle and lead sulfide technology, applied in the directions of lead sulfide, nanotechnology, nanotechnology, etc., can solve the problems of preparing thin films without lead sulfide nanopowder, and achieve easy control of preparation parameters, good repeatability, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Mix the transparent solution of sodium ethyl xanthate of 100ml 0.2mol / l with the transparent solution of lead nitrate of 100ml 0.1mol / l, fully stir to form a precipitate, filter the lotion and dry to obtain lead ethyl xanthate powder; Lead ethyl xanthate powder was dissolved and dispersed in pyridine to form a uniform solution of 500mg / ml; the uniform solution of lead ethyl xanthate was spin-coated on a Si substrate, and annealed at a temperature of 300°C and a nitrogen atmosphere for 10 minutes.

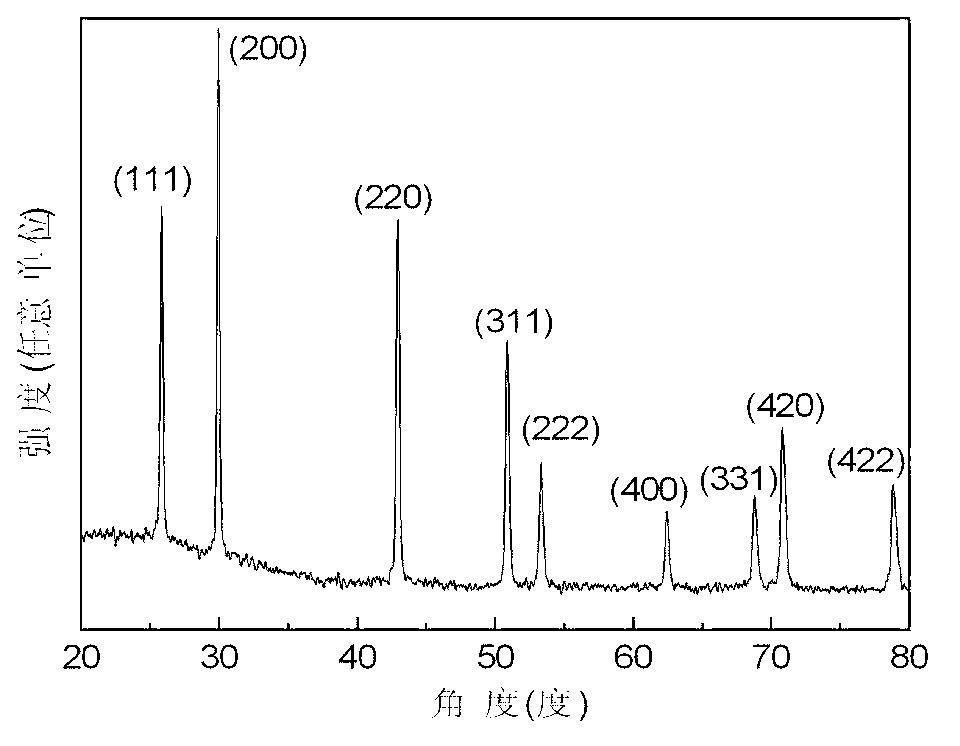

[0020] figure 1 It is the X-ray diffraction pattern of lead sulfide, which can confirm that it is lead sulfide with face-centered cubic structure.

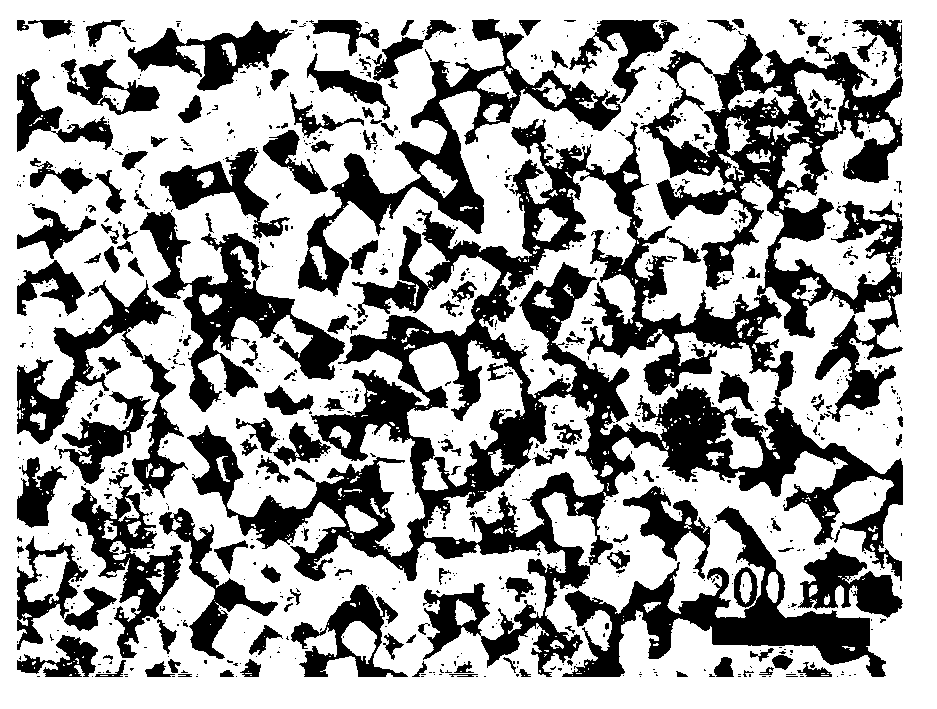

[0021] figure 2 Scanning electron micrographs of lead sulfide thin films. It can be seen from the figure that the shape of the lead sulfide nanoparticles is a cube, and the size is about 50 nanometers.

Embodiment 2

[0023] Mix the transparent solution of potassium ethyl xanthate of 50ml 0.1mol / l with the transparent solution of lead acetate of 50ml 0.2mol / l, fully stir to form a precipitate, filter the lotion and dry to obtain lead ethyl xanthate powder; Lead ethyl xanthate powder was dissolved and dispersed in pyridine to form a uniform solution of 10mg / ml; the uniform solution of lead ethyl xanthate was drip-coated on Si wafers, and dried and annealed at 120°C for 100 minutes in an air atmosphere.

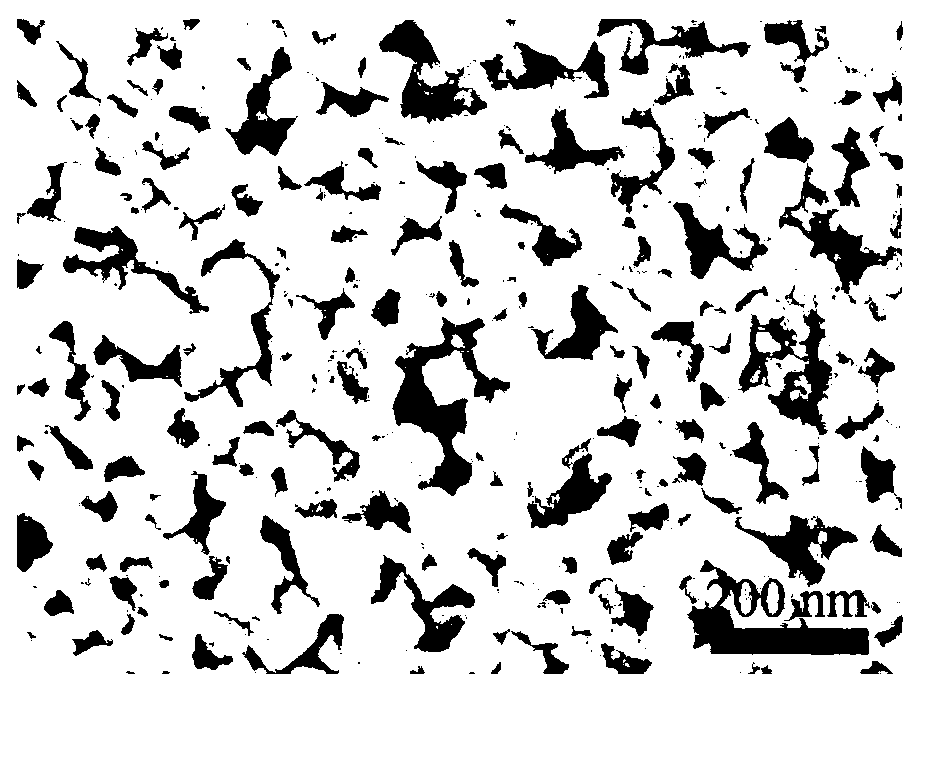

[0024] image 3 Scanning electron micrographs of lead sulfide thin films. It can be seen from the figure that the shape of the lead sulfide nanoparticles is a cube, and the size is about 30-70 nanometers.

Embodiment 3

[0026] Mix the transparent solution of sodium ethyl xanthate of 30ml 0.2mol / l with the transparent solution of lead acetate of 30ml 0.15mol / l, fully stir to form a precipitate, filter the lotion and dry to obtain lead ethyl xanthate powder; Lead ethyl xanthate powder was dissolved and dispersed in pyridine to form a uniform solution of 50mg / ml; the uniform solution of lead ethyl xanthate was dip-coated on the Si substrate, and dried and annealed for 70 minutes at a temperature of 200°C and an argon atmosphere .

[0027] Figure 4 is a scanning electron micrograph of a lead sulfide thin film. It can be seen from the figure that the shape of the lead sulfide nanoparticles is a cube, and the size is about 30-150 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com