Metal-clad laminated plate

A laminated board and metal-clad technology, which is applied in the direction of metal layered products, metal pattern materials, and the improvement of metal adhesion on insulating substrates, can solve problems such as insufficient signal transmission characteristics, and achieve excellent interlayer adhesion and high performance. Low impedance matching, satisfying quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

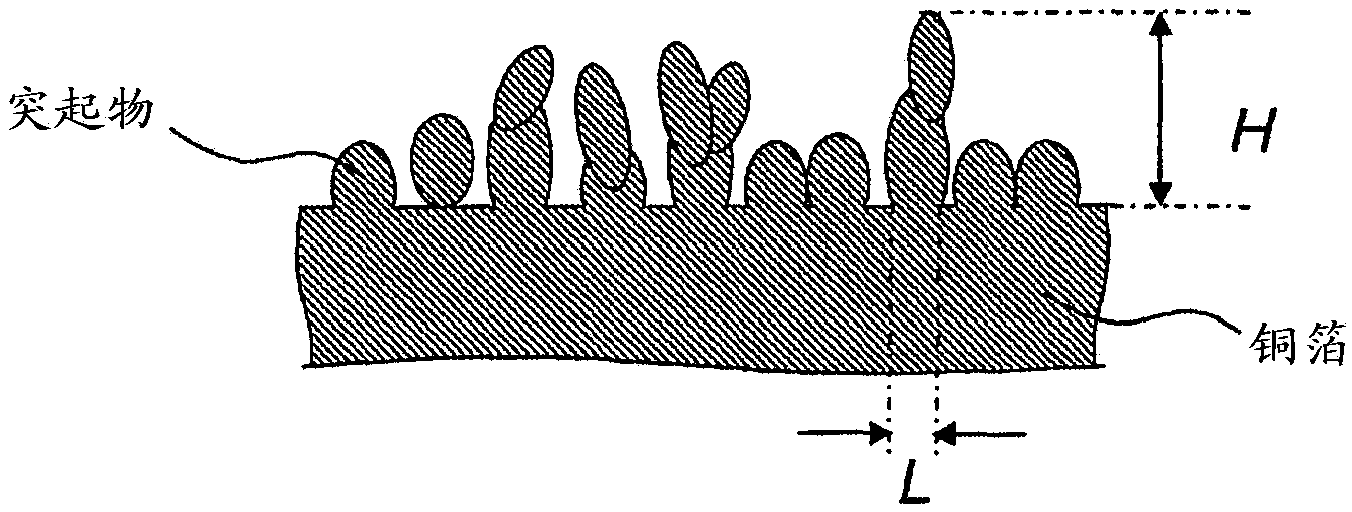

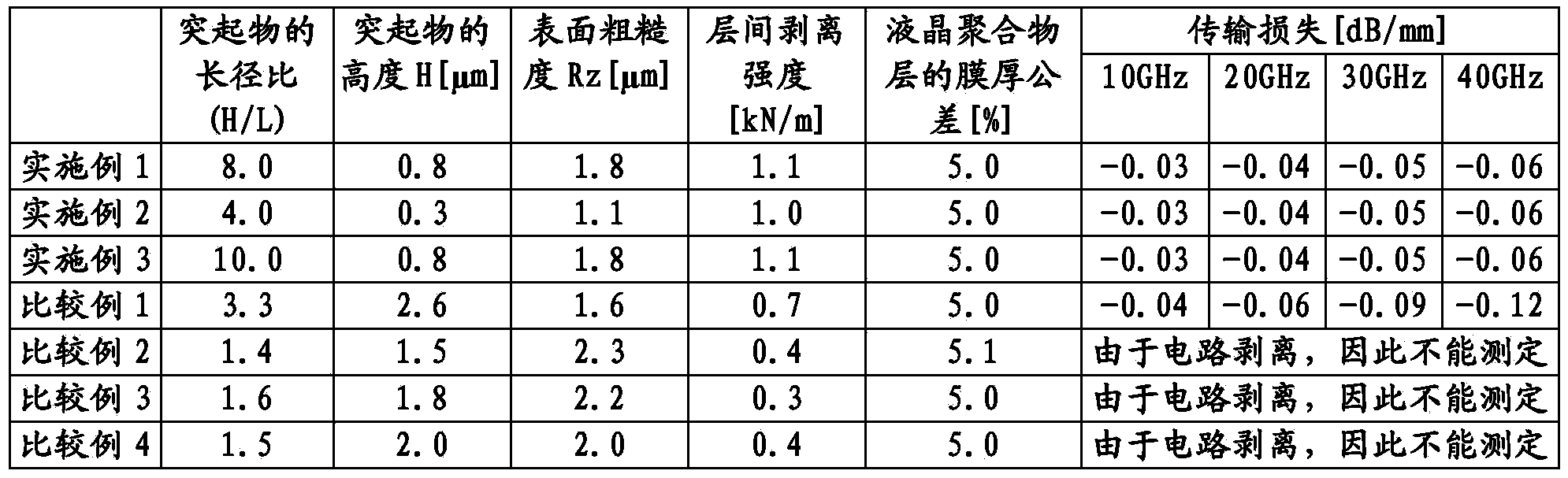

[0056] Electrolytic copper foil 1 with a thickness of 12 μm was laminated on both sides of a liquid crystal polymer film (manufactured by Japan Goatex Co., Ltd., trade name BIAC, heat distortion temperature: 300° C.) with a thickness of 50 μm and a film thickness tolerance of 5.0%. The metal-clad laminates according to Example 1 were produced by continuous thermocompression bonding between the clad metal pressure rolls. Also, using electrolytic copper foils 2 and 3 with a thickness of 12 μm, both surfaces of the liquid crystal polymer film were continuously thermocompression-bonded in the same manner as above to manufacture metal-clad laminates according to Examples 2 and 3.

[0057] Specifically, both the above-mentioned liquid crystal polymer film and the above-mentioned electrolytic copper foil were made of elongated roll materials, and were placed in a thermostatic chamber during lamination, and the surface temperature was set to 240°C (the temperature difference in the wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com