Vanadium-antimony co-doped lithium iron phosphate used as lithium ion positive pole material and preparation method thereof

A positive electrode material, lithium iron phosphate technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of not being able to improve the bulk phase transmission rate of lithium ions, poor electrochemical performance, and low volumetric energy density. Achieve superior electrochemical performance, improve specific capacity and rate discharge performance, and improve electronic and ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] In order to better understand the present invention, it will be further described below in conjunction with the examples, but the embodiments of the present invention are not limited thereto.

[0031] The typical molecular formula of the material of the present invention is as follows: vanadium antimony doped lithium iron phosphate LiFe 0.98 Sb 0.005 V 0.01 (PO 4 ) / C, LiFe 0.97 Sb 0.01 V 0.01 (PO 4 ) / C, LiFe 0.965 Sb 0.01 V 0.15 (PO 4 ) / C etc. are lithium ion cathode materials of the present invention.

Embodiment 1

[0033] Lithium carbonate, iron phosphate, ammonium dihydrogen phosphate, ammonium metavanadate and antimony trioxide according to the molar ratio of Li + : FePO 4 :H 2 PO 4 - :V 5+ : Sb 3+ =1.00: 0.98: 0.02: 0.005: 0.01 Weighing, adding glucose according to 60% of the mass of lithium carbonate, then adding absolute ethanol according to 80% of the total mass of the reactant material, and ball milling and mixing for 5 hours to obtain a uniformly mixed slurry, After being air-dried overnight at 80°C, grind it properly, put it in a carbon-covered airtight container, place it in a muffle furnace at a rate of 5°C / min to 720°C for sintering, and keep it for 8 hours. The furnace is naturally cooled to room temperature to obtain the vanadium and antimony ion co-doped lithium iron phosphate material LiFe 0.98 Sb 0.01 V 0.005 (PO 4 ) / C. For comparison, undoped lithium iron phosphate materials were also prepared under the same preparation conditions and composition ratio.

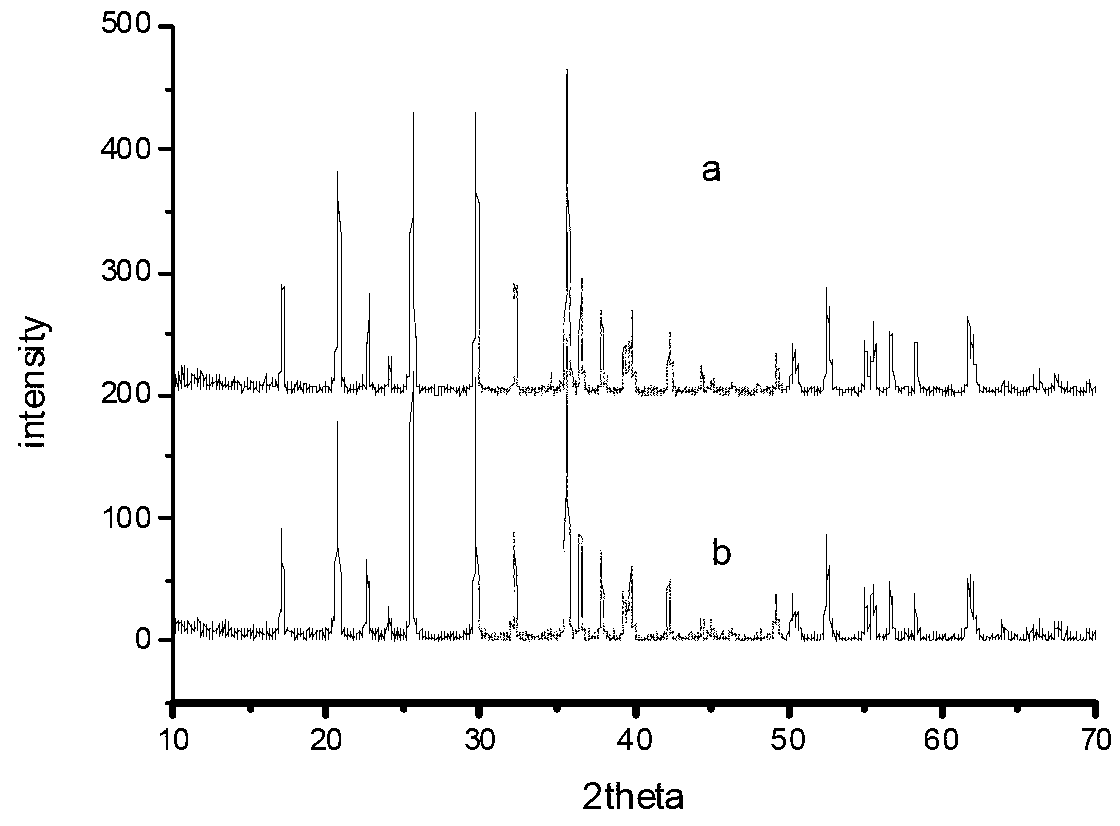

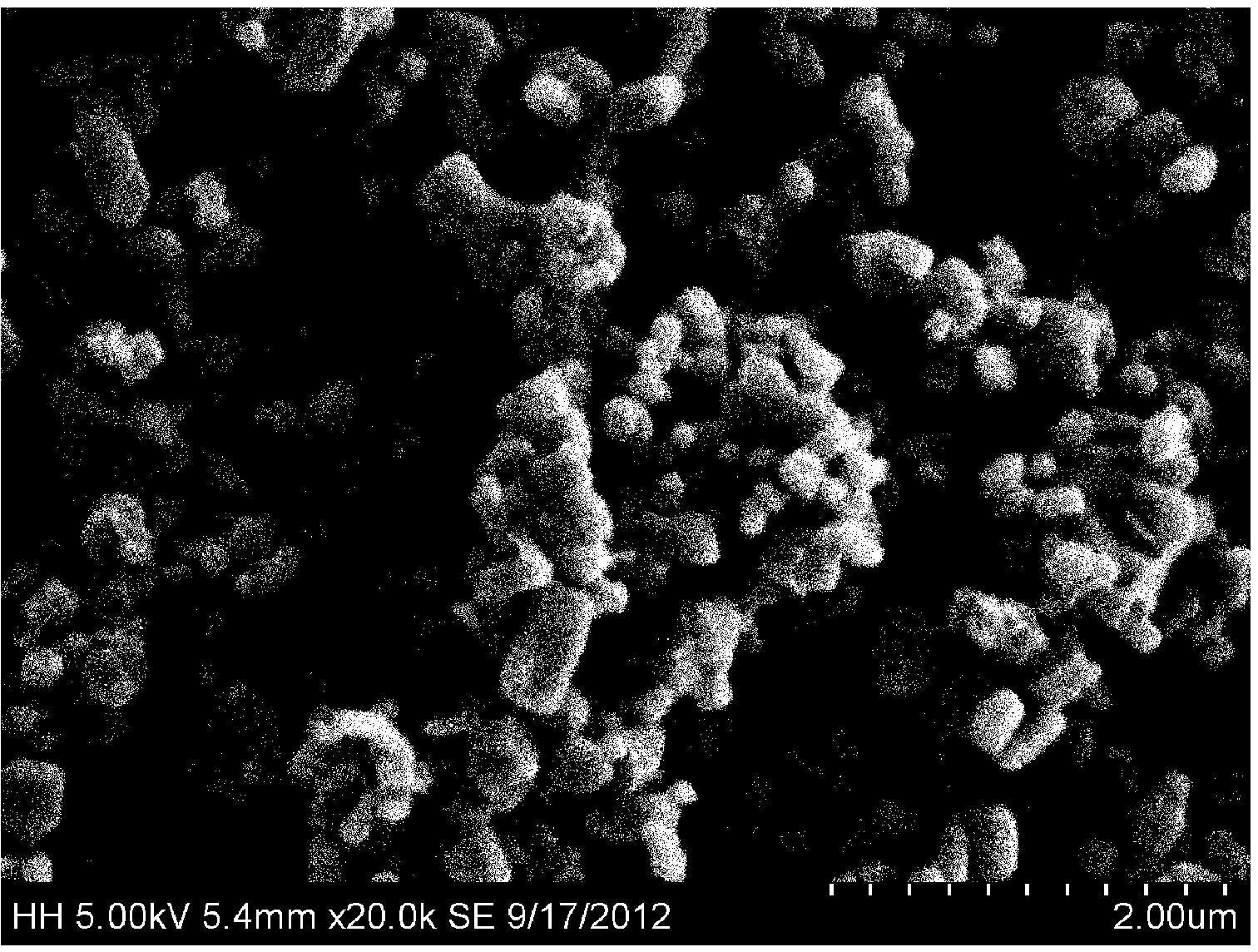

[00...

Embodiment 2

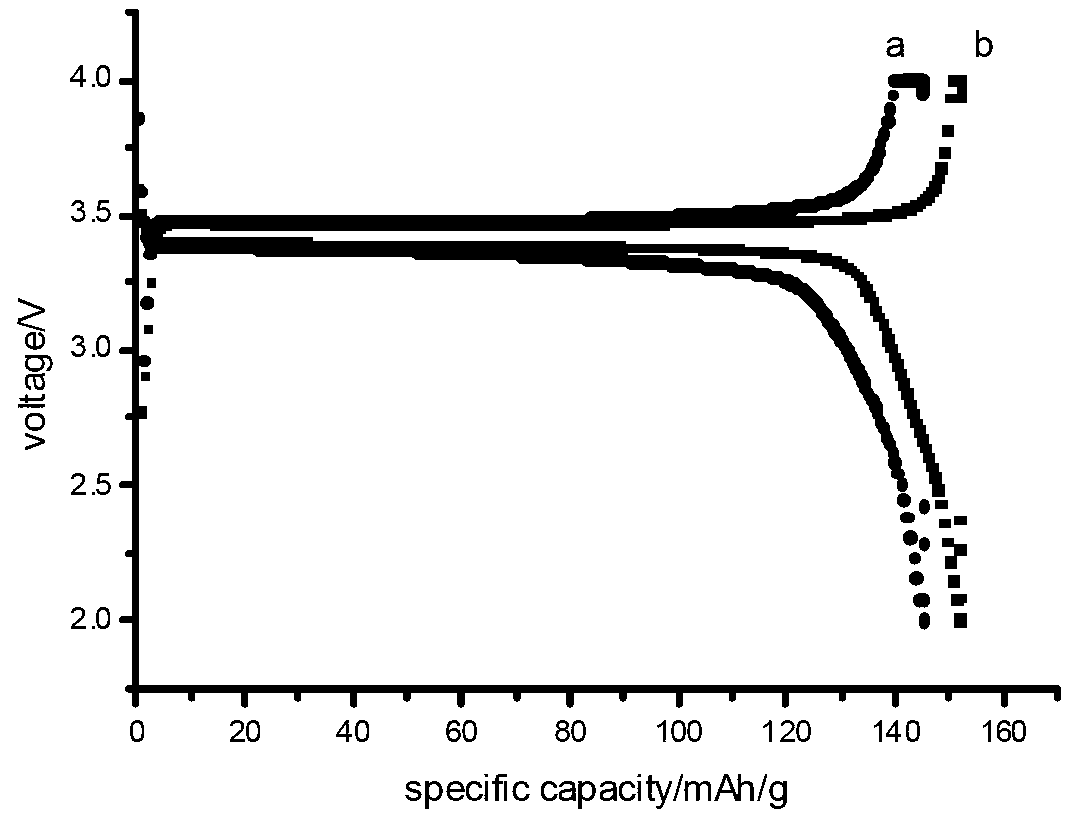

[0037] Lithium carbonate, ferrous oxalate, ammonium dihydrogen phosphate, vanadium pentoxide and antimony oxalate according to the molar ratio of Li + : Fe 2+ :V 5+ : Sb 3+ : PO 4 3- =1.00:0.97:0.01:0.01:1 Weighing, adding glucose according to 45% of the mass of lithium carbonate, then adding absolute ethanol according to 80% of the total mass of the reactant material, and ball milling and mixing for 5 hours to obtain a uniformly mixed slurry, After being air-dried overnight at 80°C, grind it properly, put it in a carbon-covered airtight container, and place it in a muffle furnace at a heating rate of 4°C / min to 700°C for sintering, keep it warm for 10 hours, and then The furnace is naturally cooled to room temperature to obtain the vanadium and antimony ion co-doped lithium iron phosphate material LiFe 0.97 Sb 0.01 V 0.01 (PO 4 ) / C. The prepared positive electrode material was assembled into a mold battery, which was charged and discharged at 0.2C and 2C in the volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com