PC (Poly Carbonate)/ABS (Acrylonitrile Butadiene S) alloy material and preparation method thereof

A technology of alloy materials and formulations, which is applied in the field of PC/ABS alloy materials and their preparation, can solve the problems of insufficient strength and poor dimensional stability, and achieve high bending strength and bending modulus, good mold filling fluidity, and processing The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

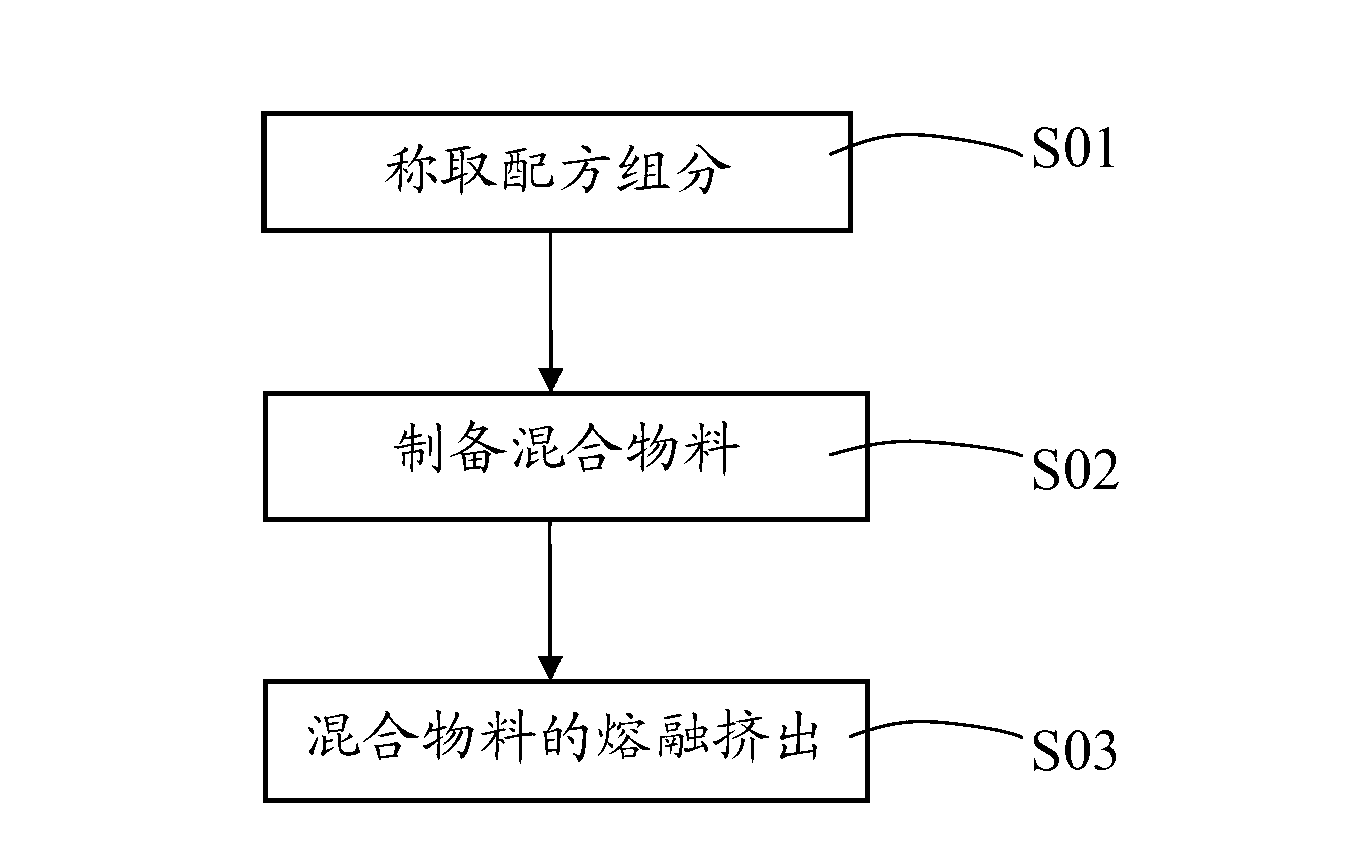

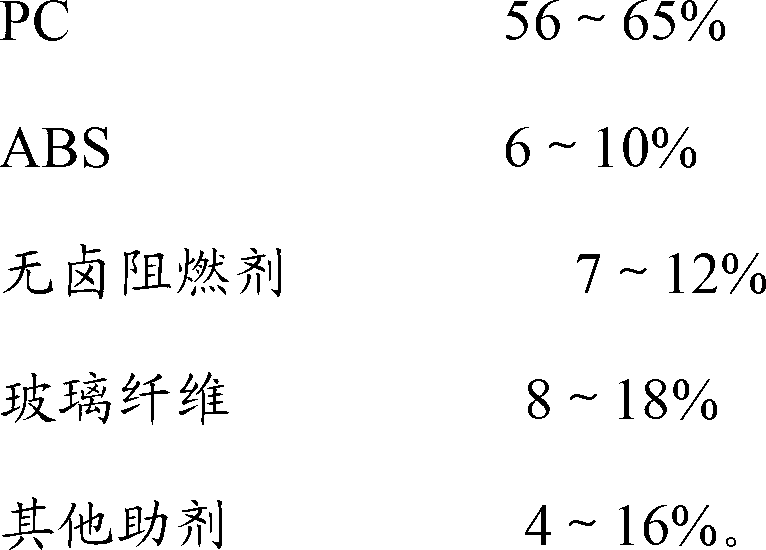

[0039] Correspondingly, the embodiment of the present invention also provides the preparation method of above-mentioned PC / ABS alloy material, and its technological process is as follows figure 1 shown. The method comprises the steps of:

[0040] S01. Weigh the formula components: weigh each component according to the formula of the above-mentioned PC / ABS alloy material;

[0041] S02. Preparation of mixed material: weighing each component in step S01 for mixing treatment to obtain mixed material;

[0042] S03. Melt extrusion of the mixed material: melt extrude the mixed material in step S02 to obtain the PC / ABS alloy material.

[0043] Specifically, the formulation of the PC / ABS alloy material in the above step S01 and the preferred contents and types of each component in the formulation are as described above, and will not be repeated here to save space.

[0044]Among them, when the silane coupling agent is preferably used as the above-mentioned number average molecular we...

Embodiment 1

[0069] The weight percentage formula components of the PC / ABS alloy material in this embodiment are shown in the following Table 1, wherein PC is Teijin PC 1250Y, ABS is Taiwan Chimei 757, and the flame retardant is Japanese bus CR- 741 concentrated phosphate ester, the glass fiber is Japanese bus CR-741 chopped glass fiber with a diameter of 3~17μm, and other additives, the toughening agent is Taiwan Guoqiao 60P, and the compatibilizer is a grafting ratio of 0.8~1.2 % of Ningbo Nengzhiguang GPM400A ABS grafted with maleic anhydride, the silane coupling agent is the self-made silane coupling agent mentioned above, the lubricant is EBS, and the antioxidant is tetrakis [β-(3,5-ditertbutyl base-4-hydroxyphenyl)propionic acid]quaternary tetraitol ester or tris(2,4-di-tert-butylphenol)phosphite, and the flame retardant and anti-dripping agent is Guangzhou Entropy SN3300B2 polystyrene-coated polystyrene Tetrafluoroethylene powder.

[0070] Its preparation method is as follows:

[...

Embodiment 2

[0078] The weight percent formulation components of the PC / ABS alloy material in this embodiment are shown in the following Table 1, wherein PC is Idemitsu PC IR2200 from Japan, ABS is Bayer GP22 from Germany, and the flame retardant is U.S. Albemarle P-30 with a phosphorus content of 6-20 % (mole percentage content) concentrated phosphate ester, the glass fiber is a glass fiber filament with a diameter of 3~17μm, and other additives, the toughening agent is Korea Kumho HR181, and the rubber content is 60~80%. Type ABS impact modifier, the compatibilizer is Shenyang Ketong KT-2ABS grafted malanic anhydride with a grafting rate of 0.8-1.2%, the silane coupling agent is the self-made silane coupling agent mentioned above, and the lubricant It is Clariant dispersant 2774 from the United States, and the antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] tetrakis tetraol ester or tris (2,4-di-tert-butyl Phenol) phosphite, flame retardant and anti-dripping ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com