Hydrophobic high oil absorption soft polyurethane foam material and preparation method thereof

A soft polyurethane and foam material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of reduced adsorption rate, low oil absorption rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

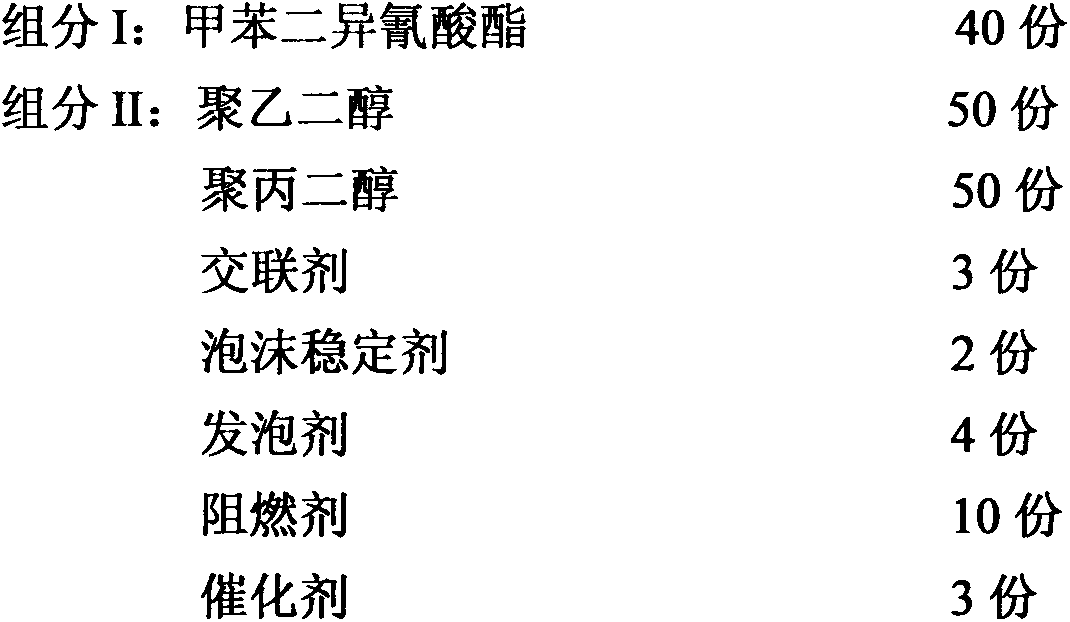

[0031] Embodiment 1 is common flexible polyurethane foam material, and formula is as follows:

[0032]

[0033] The ingredients in the component II were mixed evenly with an electric mixer to prepare the component II.

[0034] Pour component I into component II, stir rapidly with an electric stirrer for 9 seconds, pour into a self-made mold for free foaming, and cut the material after maturing to test the material properties.

[0035] The polyether polyols used for the foam in Example 1 are polyethylene glycol and polypropylene glycol, and the oil absorption rates of p-nitrobenzene, carbon tetrachloride, xylene, diesel oil and pyridine are respectively 35 g g -1 , 33.5g·g -1 , 23g·g -1 , 13.2g·g -1 , 13g·g -1 .

Embodiment 2

[0037] Embodiment 2 is common flexible polyurethane foam material, and formula is as follows:

[0038]

[0039]

[0040] The ingredients in the component II were mixed evenly with an electric mixer to prepare the component II.

[0041] Pour component I into component II, stir rapidly with an electric stirrer for 9 seconds, pour into a self-made mold for free foaming, and cut the material after maturing to test the material properties.

[0042] The polyether polyols used for the foam in Example 2 are polyethylene glycol and polypropylene glycol, and the oil absorption rates of p-nitrobenzene, carbon tetrachloride, xylene, diesel oil and pyridine are respectively 38 g g -1 , 36.2g·g -1 , 29g·g -1 , 15.5g·g -1 , 15g·g -1 .

Embodiment 3

[0044] Embodiment 3 is common flexible polyurethane foam material, and formula is as follows:

[0045]

[0046] The ingredients in the component II were mixed evenly with an electric mixer to prepare the component II.

[0047] Pour component I into component II, stir rapidly with an electric stirrer for 9 seconds, pour into a self-made mold for free foaming, and cut the material after maturing to test the material properties.

[0048] The polyether polyol used for the foam in Example 3 is polypropylene glycol, and the oil absorption rates of p-nitrobenzene, carbon tetrachloride, xylene, diesel oil, and pyridine are respectively 42 g g -1 , 41.3g·g -1 , 36g·g -1 , 17.8g·g -1 , 16.9g·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com