Method for treatment of oil sludge by microwave catalytic pyrolysis

A technology of microwave catalysis and pyrolysis of oil, which is applied in the direction of pyrolysis treatment of sludge and vaporization of by-products, etc., can solve the problems of water body and vegetation pollution, land poisoning, hindering the growth of plant roots, etc., and achieve the effect of good economical industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

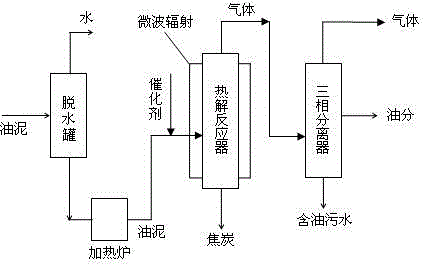

[0023] use figure 1 The process flow shown. The specific embodiment of the present invention is described by taking oil sludge at the bottom of a refinery oil tank as an example. Oil sludge contains 81% oil (mass), 12% water, and the rest is solid matter.

[0024] After the sludge is dehydrated and pretreated to remove mechanical impurities, it is heated to 350°C in a heating furnace and mixed with SeO 2 After the catalyst is mixed, it enters the pyrolysis reactor. The reaction temperature is 480°C, the mass ratio of catalyst to oil sludge is 1:50, and the reaction time is 30min / m 3 sludge. The reactor is externally connected with a microwave radiation device. The microwave radiation frequency is 2450MHz, and the power is continuously adjustable to 750W. The radiation time is the same as the reaction time. The pyrolysis gas enters the three-phase separator through the heating pipeline. In order to avoid the solidification of the pyrolysis gas, the temperature of the hea...

Embodiment 2

[0027] The specific embodiment of the present invention is described by taking oil sludge at the bottom of a refinery oil tank as an example. Oil sludge contains 65% oil, 24% water, and the rest is solid matter. The catalyst is SeO prepared by impregnation method 2 / Al 2 o 3 (SeO 2 content is 10%) catalyst, the reaction temperature is 500°C, the mass ratio of catalyst to oil sludge is 1:40, and the reaction time is 15min / m 3 sludge. The microwave radiation frequency is 2450MHz, and the power is continuously adjustable to 600W. The radiation time is the same as the reaction time.

[0028] After the oil sludge is pyrolyzed by microwave catalyst, the liquid phase yield is 87%, the 350°C fraction accounts for 41.5%, and the gas yield is 9.6% %, coke yield 3.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com