Live-working robot of transformer substation

A technology for live work and robots, applied in manipulators, manufacturing tools, etc., can solve the problems of high labor intensity, potential safety hazards, easy to cause personal casualties, etc., to avoid direct contact and improve safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and embodiments.

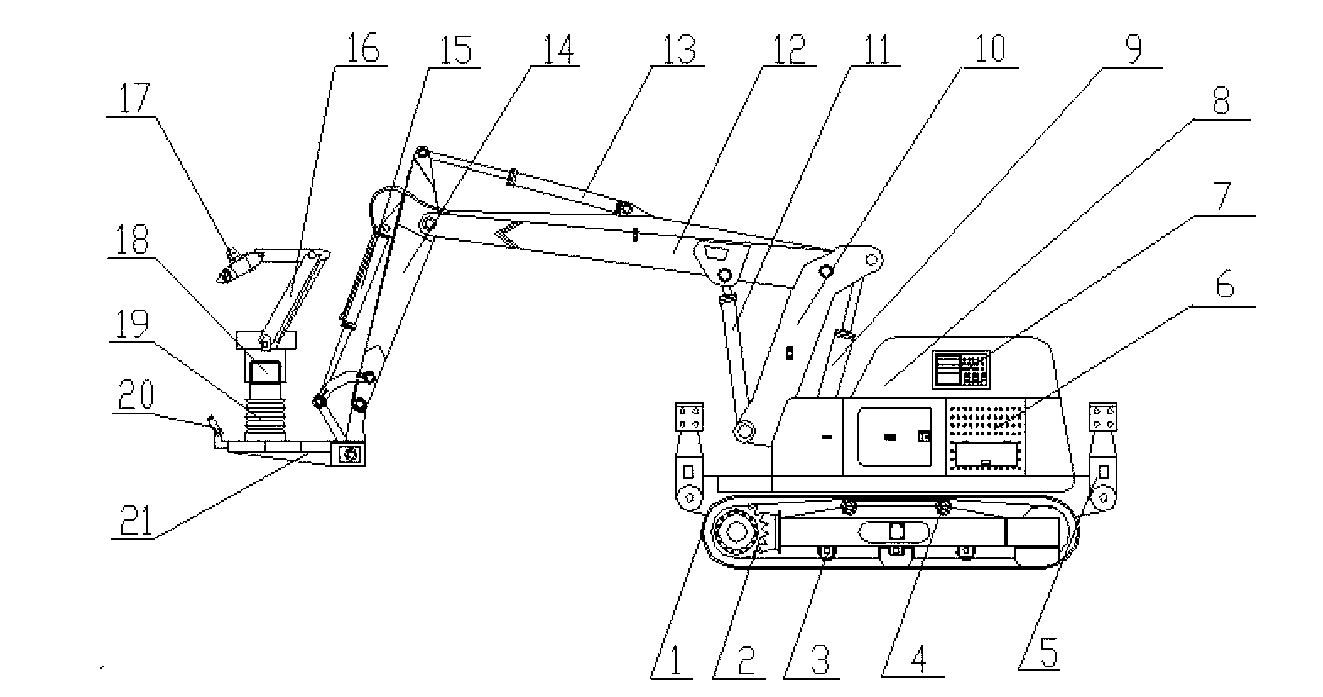

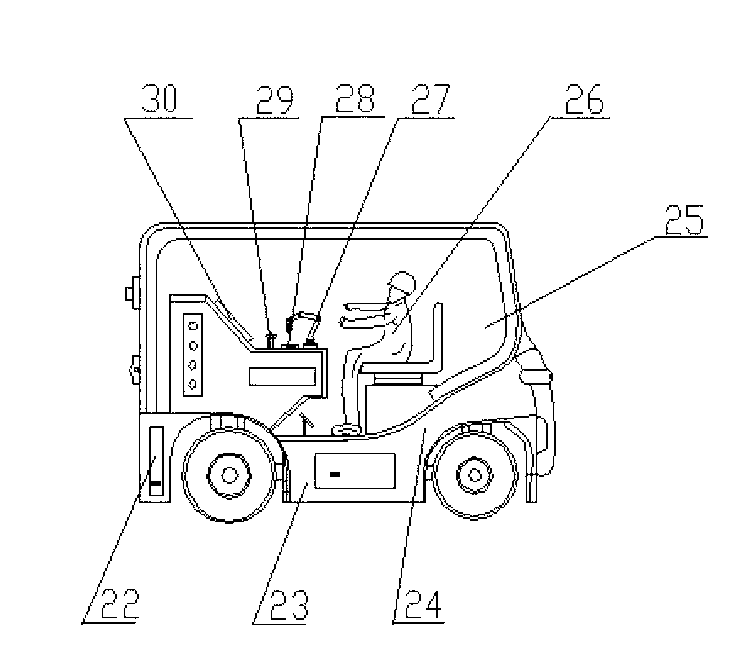

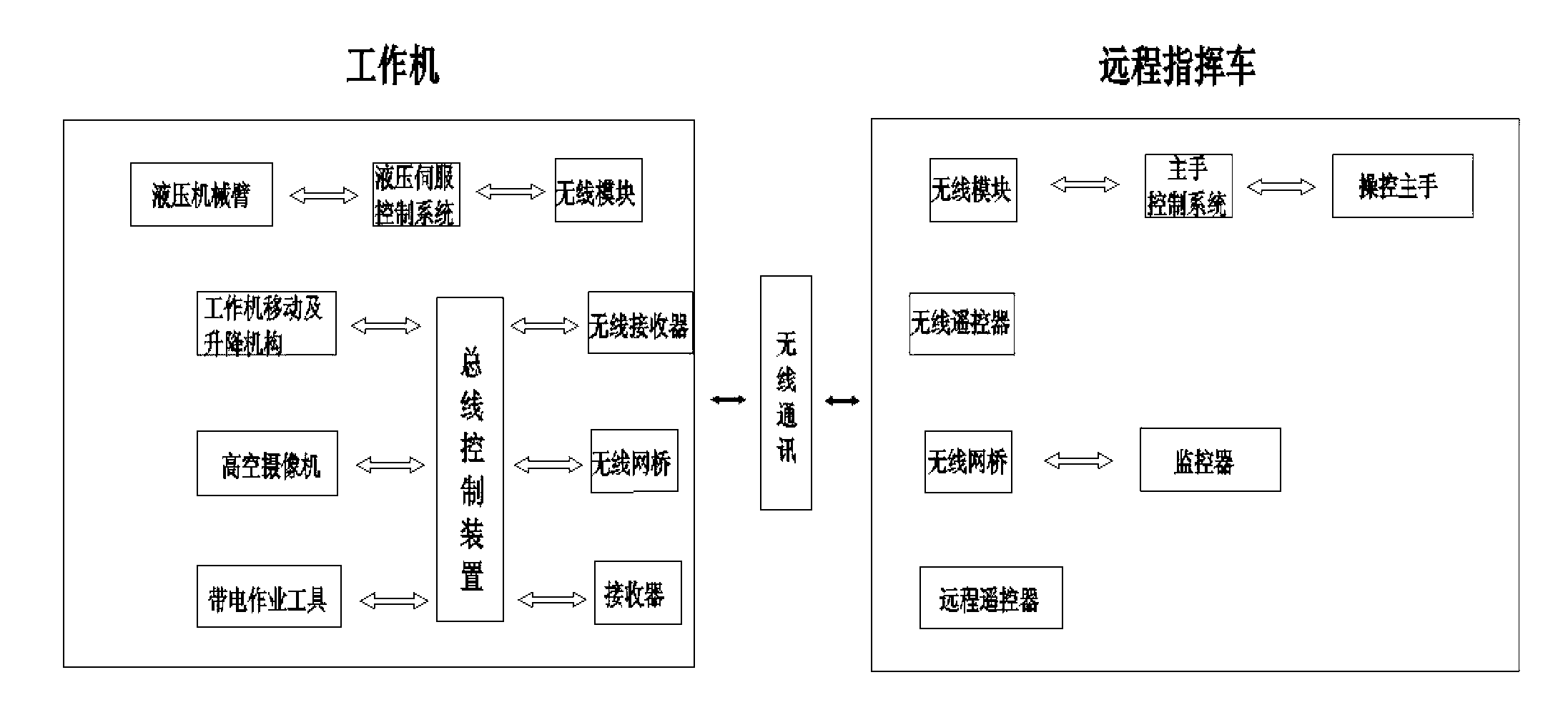

[0031] figure 1 , figure 2 Among them, a substation live working robot, the main body is composed of a working machine and a remote control command vehicle. Among them, the working machine is mainly composed of power system, actuator, control system and control system. The power system is the power source for the robot to work, and the actuator is mainly composed of a walking mechanism, a rotary platform, a lifting platform, and a six-degree-of-freedom hydraulic manipulator. The control system of the working machine is mainly composed of the hydraulic pump 34, the lower electromagnetic reversing valve group A 57, the central conversion joint 56, the upper-mounted electromagnetic reversing valve B group 54, the mechanical arm hydraulic servo valve C group 40, and each arm drive cylinder and rotary motor. . The robot control system adopts the master-sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com