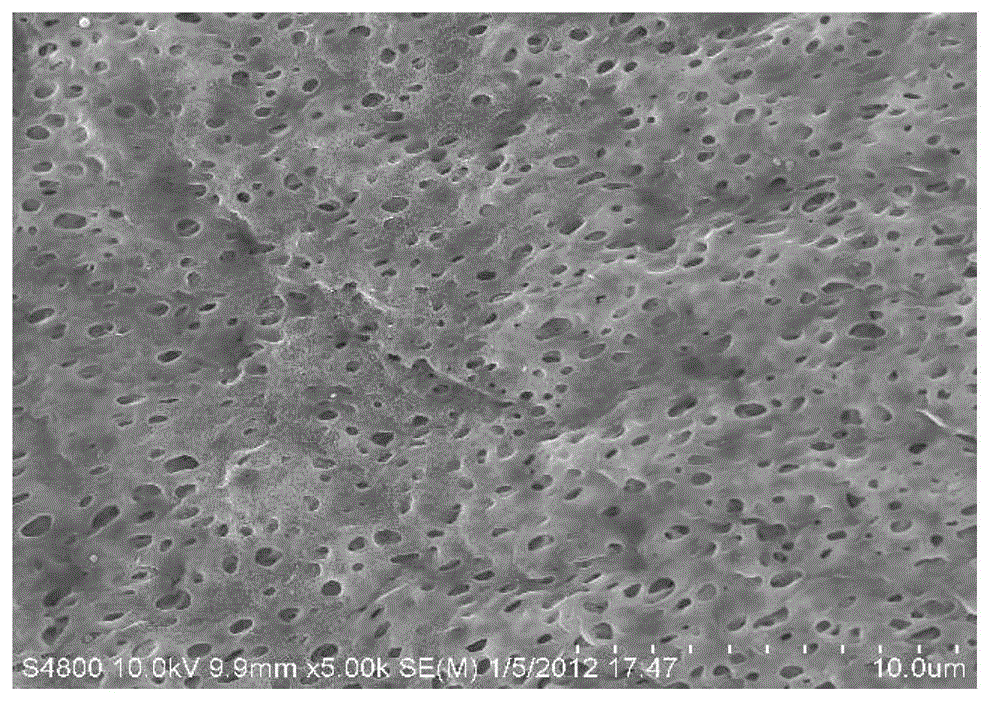

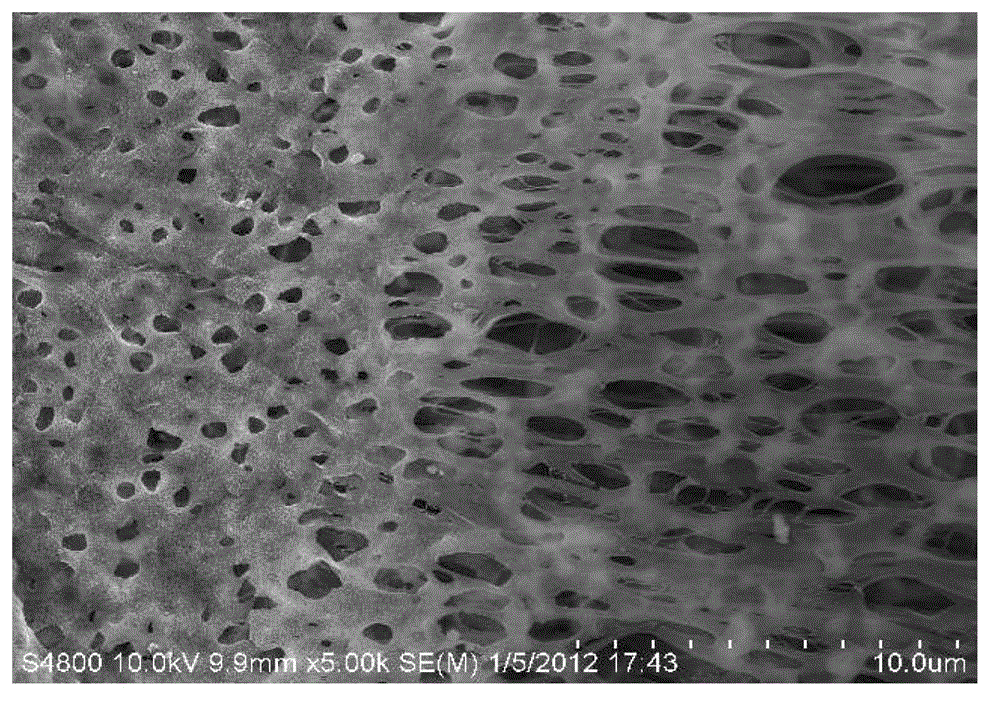

Hydrophilic modified PVDF and PU mixed taper hole ultrafilteration membrane and preparation method thereof

A hydrophilic modification and ultrafiltration membrane technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of shortening the service life of ultrafiltration membranes, blockage of retentate membrane pores, broken wires, etc. Achieve the effects of improving anti-fouling performance, anti-fouling ability, and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0060] A method for preparing the above-mentioned hydrophilic modified PVDF and PU blended conical pore ultrafiltration membrane is characterized in that it specifically comprises the following steps:

[0061] (1) Pretreatment of polymer materials, put a certain amount of PVDF, PU, and polyvinylpyrrolidone into different thermal dryers for drying, and the drying temperatures are 95°C-115°C and 65°C-90°C respectively , 50°C-80°C;

[0062] (2) Weigh 70kg of dimethylacetamide (DMAC), 18kg of polyvinylidene fluoride (PVDF), 2kg of polyurethane nylon (PU), 4kg of polyvinylpyrrolidone (PVP), 6kg of polyvinylpyrrolidone (PVP), and Ethylene glycol 600 (PEG) was successively placed in a stirred reactor, stirred at a constant temperature of 100°C at a speed of 120 rpm for 18 hours, and then the stirred mixed solution was transferred to a nitrogen blanketing pressure of 35-45 mm water column ( mmH20), temperature is 80 ℃, vacuum degassing 18h in the feed liquid tank of vacuum degree 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com