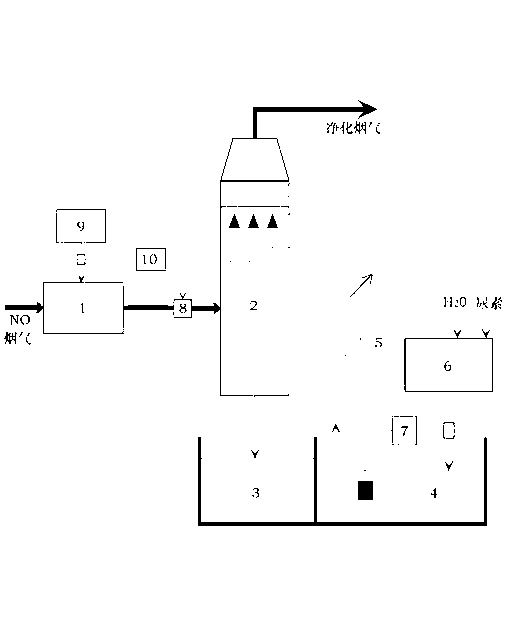

Two-step oxidation-reduction flue gas denitration method

A flue gas and denitrification technology, applied in the field of flue gas denitrification, can solve the problems of high energy consumption, ammonia escape, ammonia leakage, etc., and achieve the effects of low investment and treatment cost, high ozone utilization rate, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A company has a 10-ton heating chain furnace with a coal-fired flue gas volume of 33,000m 3 / h, the flue gas NO concentration is about 560mg / m 3 , the original flue gas denitrification system. The new denitrification design adopts the denitrification method of the present invention. The inner diameter of the reduction reaction tower is 1.5m, the height of the tower body is 10m, the material can be stainless steel, 3-layer spray is used, and the nozzle is a stainless steel spiral nozzle. The rated output of the ozone generator is 18kg / h, the inner diameter of the cylinder of the ozone oxidation device is 1.6m, and the length of the cylinder is controlled at 6m. The mass concentration of urea in the circulating reducing agent solution is 5%, and the operating water-gas ratio is 8L / m 3 , the aqueous solution is recycled, and the denitrification efficiency reaches 85.1% according to the test of the environmental protection monitoring department. The system is reliable in ...

Embodiment 2

[0034] A company has a 20-ton heating fluidized furnace with a coal-fired flue gas volume of 70,000m 3 / h, the flue gas NO concentration is about 460mg / m 3 , the original flue gas denitrification system. The new denitrification design adopts the denitrification method of the present invention. The inner diameter of the reduction reaction tower is 2.4m, and the height of the tower body is 12m. The rated output of the ozone generator is 28kg / h, the inner diameter of the cylinder of the ozone oxidation device is 2.2m, and the length of the cylinder is controlled at 8m. The mass concentration of urea in the circulating reducing agent solution is 4%, and the operating water-gas ratio is 10L / m 3 , the aqueous solution is recycled, and the denitrification efficiency reaches 83.2% according to the test of the environmental protection monitoring department. The system is reliable in operation, the denitrification effect is good, and the operating cost is low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com