Efficient stokerfeed boiler ozonation desulfurization and denitrification integrated process system

A technology of ozone oxidation, desulfurization and denitrification, applied in gas treatment, chemical instruments and methods, membrane technology, etc., to achieve the effect of wide application range, short construction period and small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

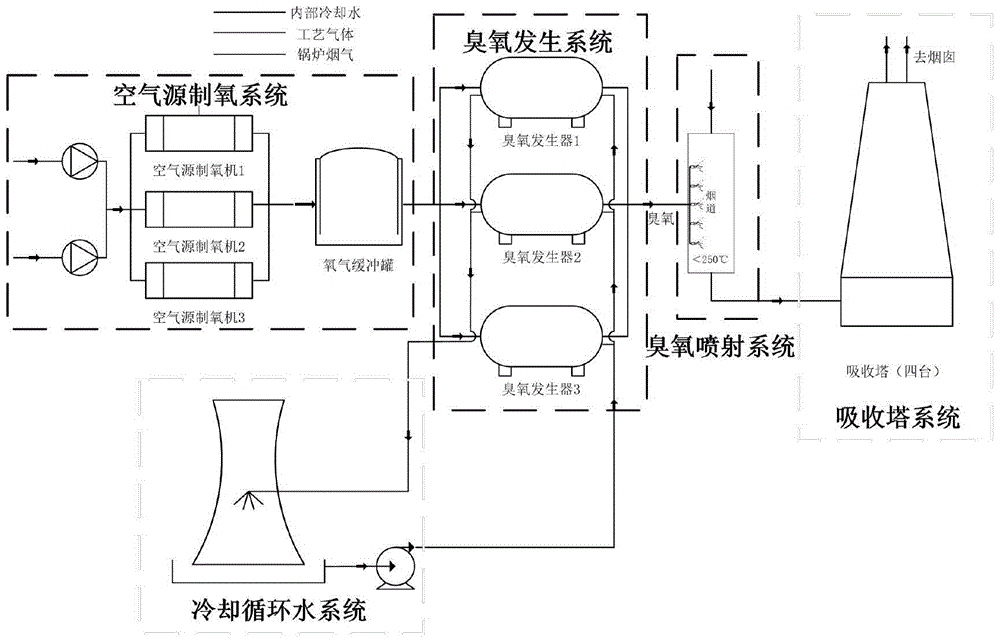

[0027] The present invention is described in further detail below in conjunction with process system diagram:

[0028] refer to figure 1 , a high-efficiency chain furnace ozone oxidation desulfurization and denitrification integrated process system is characterized in that it includes an air source oxygen production system for preparing oxygen, an oxygen buffer tank connected to the air source oxygen production system through pipelines, and An ozone generation system that converts the oxygen in the oxygen buffer tank into ozone; the ozone generation system passes ozone into the absorption tower system for absorbing nitrogen oxides, and the system also includes an ozone injection system, which is arranged in the Between the ozone generation system and the absorption tower system, it is used to inject the ozone into the flue at a suitable position of the boiler.

[0029] In addition, the ozone generating system is connected with a circulating cooling water system through pipeline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com