Brake axle load integrated-type axle load measuring device

A measuring device and an integrated technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems that affect the accuracy of measurement results, reduce test accuracy, and reduce work efficiency, so as to shorten working hours, Reduce work difficulty and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure and working process of the present invention will be described in detail below according to the accompanying drawings.

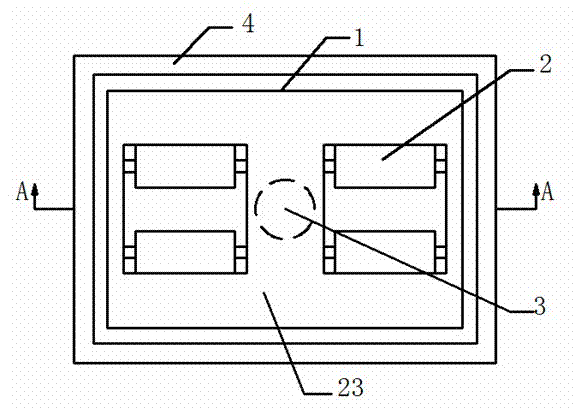

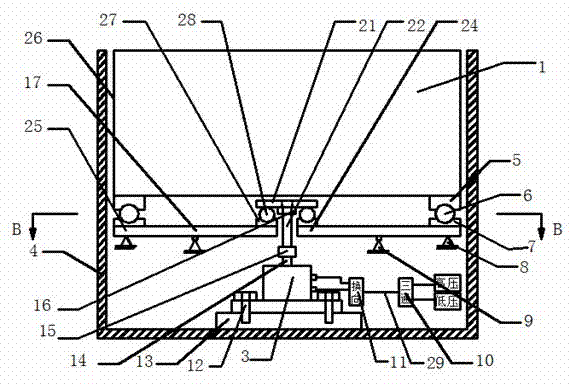

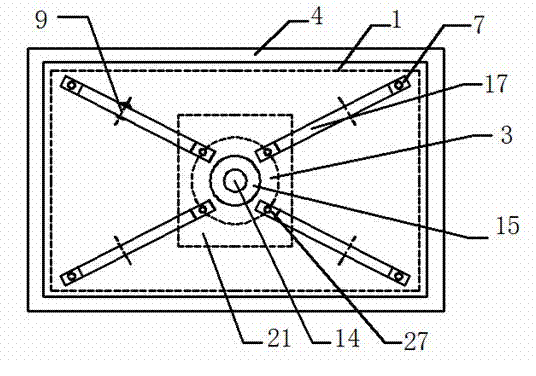

[0022] Such as Figure 1 to Figure 4 As shown, the brake axle load integrated axle load measuring device of the present invention includes a drum type brake force test bench 1, a pressure plate 21, a pull rod 22, a load cell 15, a working cylinder 3, a first connecting piece, a second connecting piece and a Four working levers 17 on the same horizontal plane; wherein, each first connecting part comprises the first lower ball seat 27 and the first steel ball 28, and each second connecting part comprises the second upper ball seat 5, the second steel ball 6 and the second lower tee 7.

[0023] The first end 24 of each working lever 17 is respectively connected with the pressing plate 21 by a first connecting piece, and the second end 25 of every working lever 17 is respectively connected with the frame of the drum type braking force test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com