Steam wet combustion total heat type lifting energy-saving stove

An all-heat, energy-saving stove technology, applied in the field of gas stoves, can solve the problems affecting the quality of life, black marks on the bottom of the pot, slow heating speed, etc., and achieve the effects of increasing the burning area, no sanitary dead corners, and expanding the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

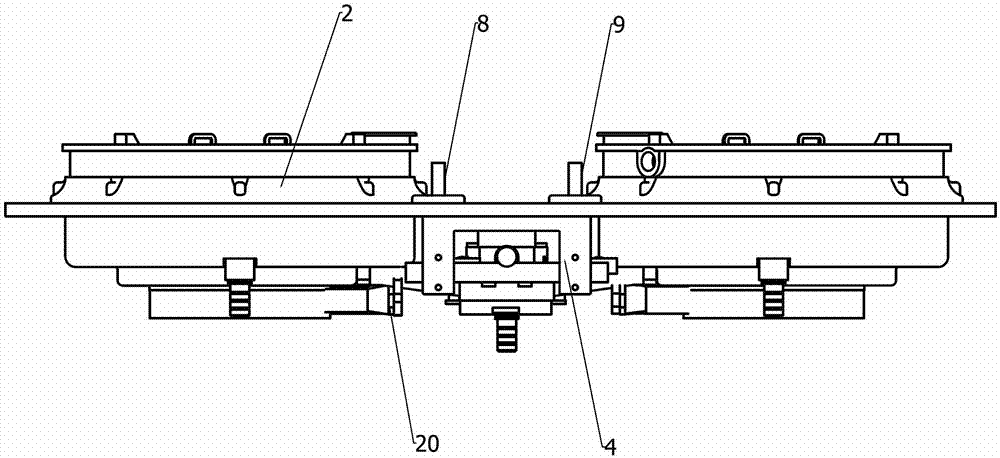

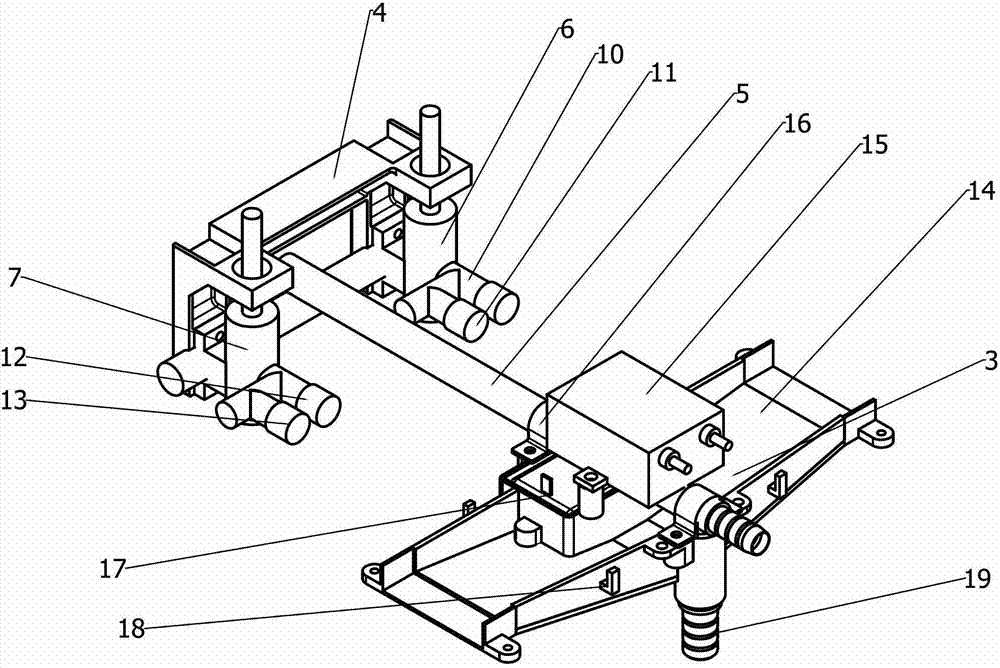

[0036] Such as Figure 1~12 As shown, the present invention mainly includes a panel 1, a stove 2, an air supply bracket 4, an air supply pipe 5, a first air valve 6, a second air valve 7, a main board 14, an igniter 15, a pressing plate 16, a battery box 17 and main board drainage Mouth 19.

[0037] Two stoves 2 are distributed symmetrically on the left and right sides of the panel 1 , and a gas supply bracket 4 is arranged between the two stoves 2 . The output end of the air supply pipe 5 is fixed inside the air supply bracket 4, and the left and right sides of the air supply pipe 5 are respectively connected with the first air valve 6 and the second air valve 7. The upper end of the first air valve 6 is connected to the first knob 8 , the side of the first air valve 6 is connected to the first low fire air supply port 10 , and the first small fire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com