High-thermal-conductivity PP (polypropylene)-based composite material and preparation method thereof

A technology of polypropylene-based and composite materials, which is applied in the field of high thermal conductivity polypropylene-based composite materials and its preparation, can solve the problems of limitations, low thermal conductivity, large amount of thermal conductive fillers, etc., and achieve the effect of good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A formula of a high -guide heat polypropylene compound material is composed as follows 1:

[0019] Table 1: The formula of the reconciliation material of the high -guide thermal polypropylene compound material

[0020] raw material Quality Polytes 1102K 80 PP-G-MAH 5 Surface modification high -efficiency thermal conductivity 15 Antioxidant 1010 0.5 Silicane coupling agent KH560 1

[0021] The surface modification high -efficiency thermal conductors described in the table are prepared: the aid, high -efficiency thermal graphene nano tablet (model: XF067), diamond powder, ethanol, and ethanol can be fully mixed into pulp;The auxiliary agent is a mixture of 1: 1 in the mass ratio of 1: 1.The quality of graphene nano tablets and diamond powder and the percentage of the percentage in the slurry are 25%, and the quality ratio of high -efficiency thermal graphene nano tablets and diamond powder is 20: 1.

Embodiment 2

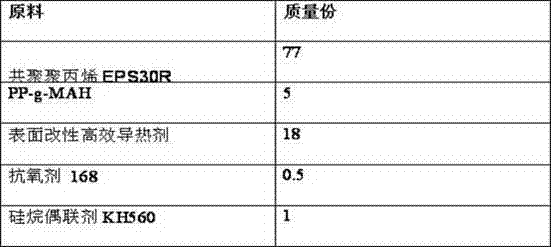

[0023] A formula of a high -guide heat polypropylene compound material is composed of Table 2: 2:

[0024] Table 2: The formula of the reconciliation material of the high -guide thermal polypropylene compound material

[0025]

[0026] The surface modification high -efficiency thermal conductors described in the table are prepared: the aid, high -efficiency thermal graphene nano tablet (model: XF067), diamond powder, ethanol, and ethanol can be fully mixed into pulp;The auxiliary agent is a mixture of 1: 1 in the mass ratio of 1: 1 in Byk-356) in the Byk-356;The quality of graphene nano tablets and diamond powder and the percentage percentage occupied in the slurry are 20%, and the quality ratio of high -efficiency thermal graphene nano tablets and diamond powder is 10: 1.

Embodiment 3

[0028] A formula of a high -guide heat polypropylene compound material is composed as follows 3: 3:

[0029] Table 3: The formula of the reconciliation material of the high -guide thermal polypropylene compound material

[0030] raw material Quality Polytes 1102K 75 PP-G-MAH 5 Surface modification high -efficiency thermal conductivity 20 Antioxidant 1098 0.5 Silicane coupling agent KH560 1

[0031] The surface modification high -efficiency thermal conductors described in the table are prepared: the aid, high -efficiency thermal graphene nano tablet (model: XF067), diamond powder, ethanol, and ethanol can be fully mixed into pulp;The auxiliary agent is a mixture of 1: 1 in the mass ratio of 1: 1.The quality of graphene nano tablets and diamond powder and the percentage of the pulp are 30%, and the mass ratio of high -efficiency thermal graphene nano tablets and diamond powder is 100: 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com