Device and method for refining dimethylbenzene

A refining device and refining method technology, which is applied in the production of bulk chemicals, organic chemistry, distillation purification/separation, etc., can solve the problems of increasing clay consumption and investment, and achieve the effect of increasing product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

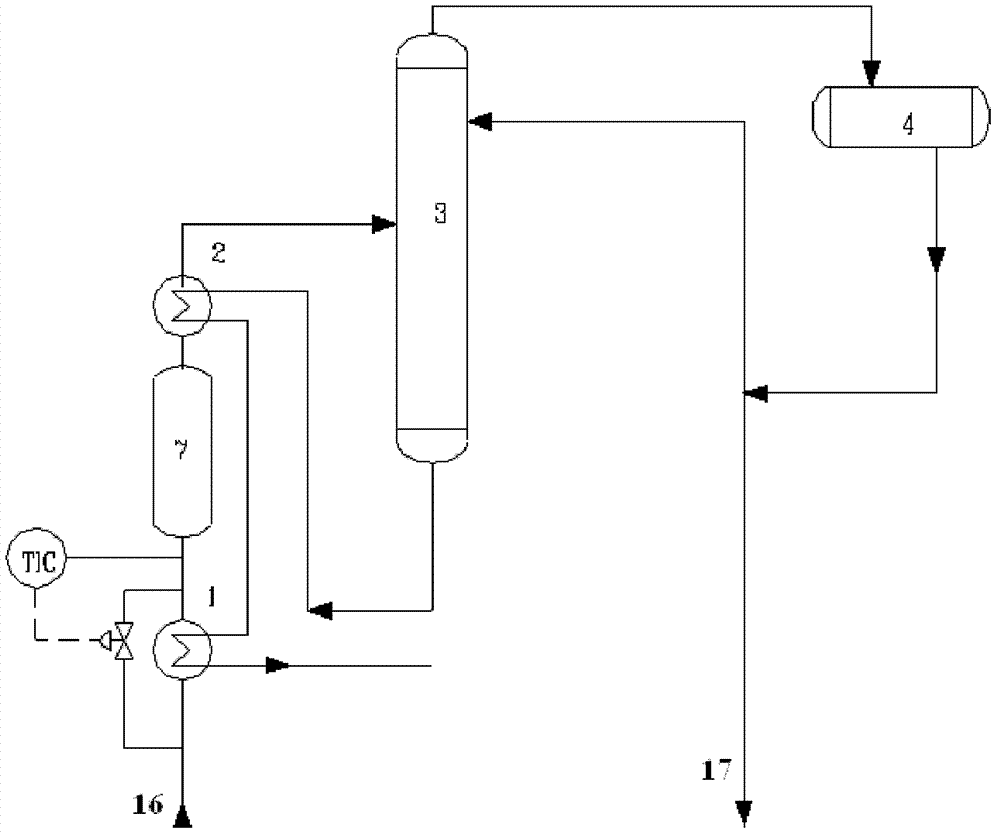

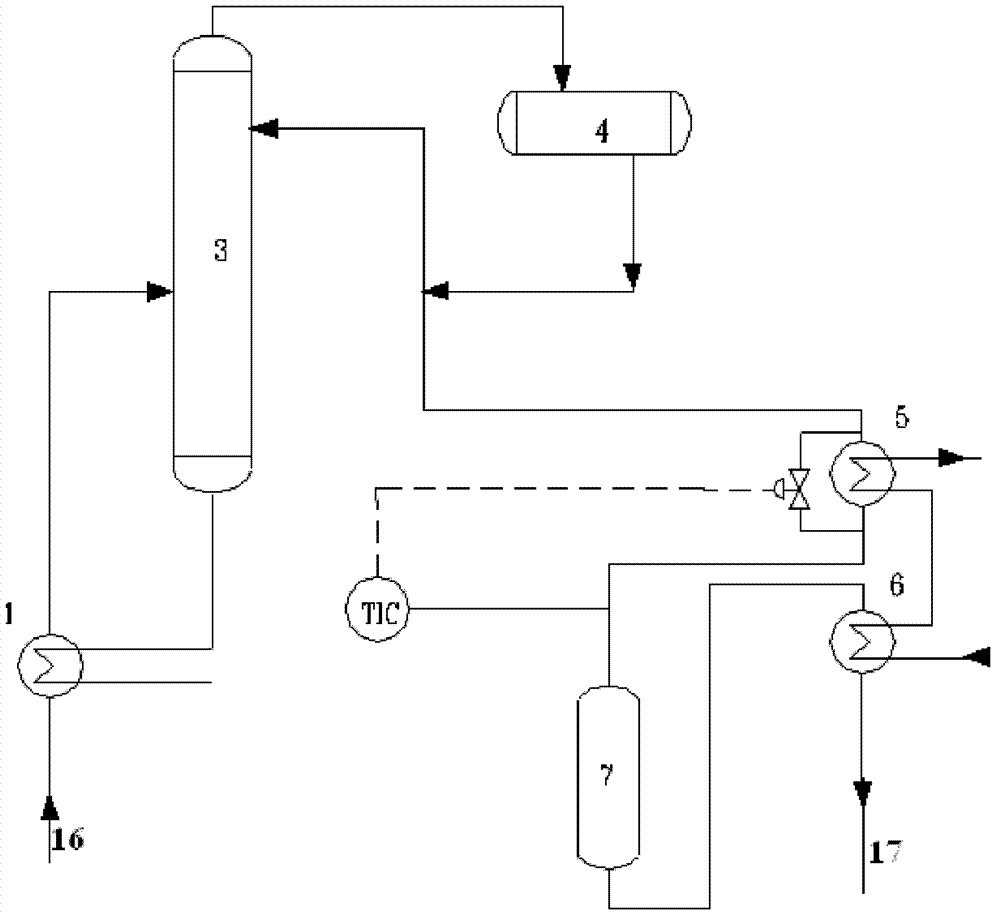

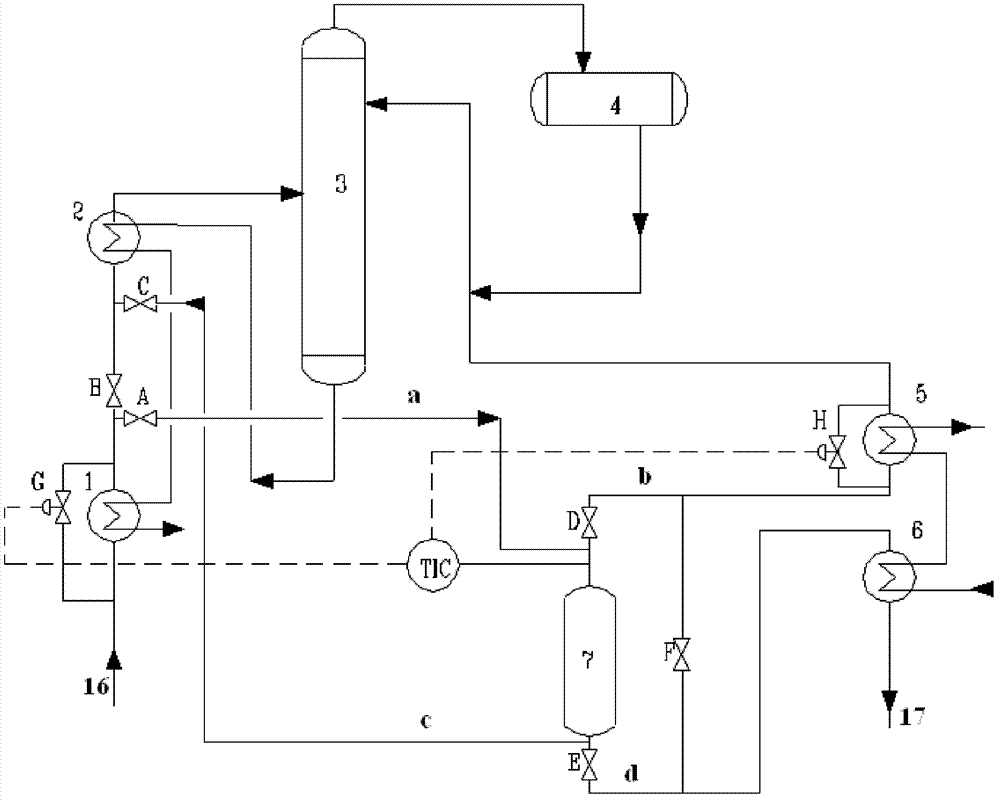

[0046] Such as image 3 Shown, a kind of refining device of continuous reformer xylene comprises: xylene tower 3 and clay tower 7,

[0047]Heat exchanger I1 and heat exchanger II2 are arranged on the feed pipeline, heat exchanger II2 is connected to xylene tower 3, heat exchanger I1 and heat exchanger II2 are provided with switch valve B9, heat exchanger I1 and switch valve The pipeline a is drawn between B9 to the top of the clay tower 7, on which a switching valve A8 is set; the top of the clay tower 7 leads to another pipeline b, on which a switching valve D11 is arranged, and is introduced into the xylene tower 3 after passing through the heat exchanger V5 upper part;

[0048] The outlet at the bottom of the clay tower 7 leads to two pipelines respectively, wherein the pipeline c communicates with the pipeline between the switching valve B9 and the heat exchanger II2, and is provided with a switching valve C10; wherein the pipeline d is provided with a switching valve E12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com