Degreasing method of super heavy oil wastewater

A technology for super-heavy oil and waste water, which is applied in separation methods, grease/oily substance/floating matter removal devices, liquid separation, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

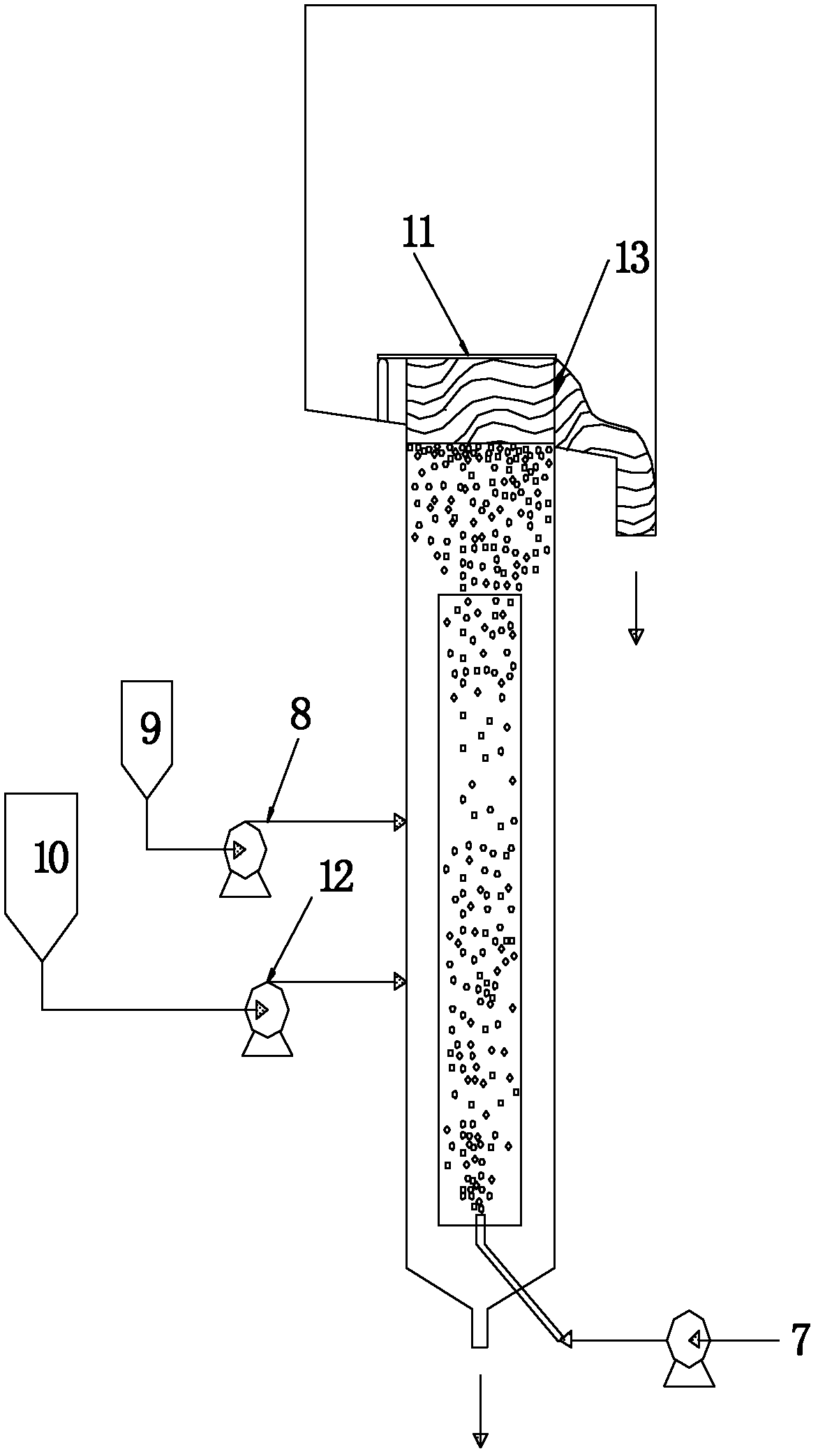

[0035] Adopt continuous operation mode, demulsification-circulation air flotation-oil scraping to separate heavy emulsified oil in wastewater.

[0036] The wastewater is super-heavy oil processing wastewater from an oil refinery, with a total COD of 42,000 mg / L, of which emulsified oil and other colloidal suspended solids account for 40,000 mg / L of COD, and the average diameter of emulsion droplets is 2.5 μm. The diameter ratio of the bubble section and the foam section of the circular foam separation tower is 1:1.4, and the height ratio is 1:0.8; the diameter ratio of the foam section overflow tank weir to the bubble section is 1:1, and the overflow tank weir and the foam section The height ratio is 0.3:1. The guide cylinder is a secondary guide cylinder; the center of the bottom of the reactor is equipped with a special micropore (average pore diameter of 3 μm) columnar gas distributor (diameter 20mm, height 60mm), and the liquid capacity is 42L. The demulsifier is polyethe...

Embodiment 2

[0038] Batch operation mode, demulsification-circulation air flotation-oil scraping is adopted to separate heavy emulsified oil in wastewater.

[0039] Waste water and device are with embodiment 1. The demulsifier is aliphatic amine PAE 1912, the dosage is 6.0g, and it is prepared into an aqueous solution with a concentration of 60g / L, which is added to the bubbling section at a flow rate of 10mL / h; the superficial gas velocity is 1.1cm / s, and the oil scraper It is a belt-type oil scraper, the ratio of the bandwidth to the diameter of the bubble section of the circulating foam separation tower is 0.7:1, and it starts once every ten minutes; the separation time is 1.5h. The COD of the effluent is 1400mg / L, and the removal rate of emulsified oil reaches 97%. Wastewater yield was 98%.

Embodiment 3

[0041] This example shows the removal effect of emulsified oil under the condition of different demulsifiers and their dosage, and adopts batch operation.

[0042] Waste water, device, demulsifier and its consumption and feeding method, oil scraper, and residence time are all the same as in Example 1. The superficial gas velocity is 1.1cm / s, and the separation time is 2h. The demulsifier adopts five schemes. Plan A: polyether demulsifier DL32, formulated as an aqueous solution with a content of 40g / L, and the flow acceleration rate is 0.1L / h; Plan B: demulsifier cationic alkyl glycoside demulsifier CAPG-131, formulated with a content of 38g / L Aqueous solution, flow acceleration rate 0.1L / h; Plan C: The demulsifier is the demulsifier cationic alkyl glycoside demulsifier CAPG-08143, which is prepared into an aqueous solution with a content of 42g / L, and the flow acceleration rate is 0.1L / h; Plan D: Break Emulsion TJ-3, prepared as an aqueous solution with a content of 42g / L, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com