Preparation method of fluoride

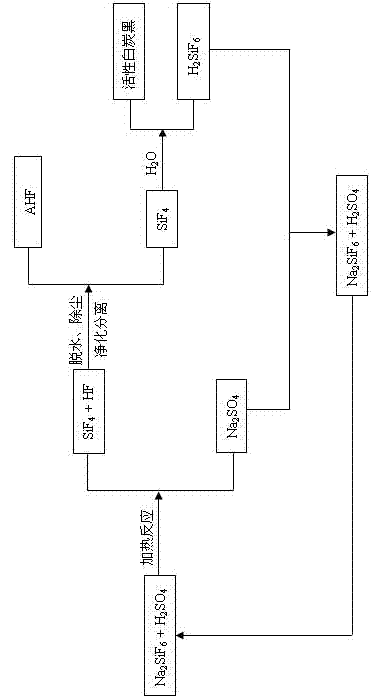

A technology of fluoride and silicon tetrafluoride, applied in the direction of fluorine/hydrogen fluoride, silicon oxide, silicon dioxide, etc., can solve the problem that the downstream products of sodium fluorosilicate cannot achieve high-efficiency and high-efficiency comprehensive utilization and comprehensive silicon resources. Utilize the problems of low added value and low economic benefits to achieve the effect of avoiding waste water and slag, efficient utilization and less environmental load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] At 80°C, add 1000g of sodium fluorosilicate and an equal amount of concentrated sulfuric acid into the reactor for reaction to obtain hydrogen fluoride and silicon tetrafluoride gas, and sodium sulfate as a by-product. The two gases are dehydrated, dust-removed, condensed and separated to obtain anhydrous hydrogen fluoride product. Silicon tetrafluoride gas is passed into water, the molar ratio of silicon tetrafluoride and water is controlled at 3:2, the pressure of silicon tetrafluoride gas is controlled at 400mbar, the hydrolysis temperature is controlled at 20°C, and the hydrolysis time is controlled at 40min to obtain active white Carbon black and fluosilicic acid solution, after suction filtration, the vacuum degree is controlled at 0.02MPa, the amount of washing and washing water is controlled at 10% of the filter cake, drying, and the drying temperature is controlled at 100°C, and dried for 2 hours to obtain the activated white carbon black product. The fluorosil...

Embodiment 2

[0028] Under the temperature condition of 120°C, add 1000g of sodium fluorosilicate and an equal amount of concentrated sulfuric acid into the reactor for reaction to obtain hydrogen fluoride and silicon tetrafluoride gas, and sodium sulfate as a by-product. The anhydrous hydrogen fluoride product is obtained after dehydration, dust removal and membrane separation of the two gases. Silicon tetrafluoride gas is passed into water, the molar ratio of silicon tetrafluoride and water is controlled at 3:3, the pressure of silicon tetrafluoride gas is controlled at 600mbar, the hydrolysis temperature is controlled at 40°C, and the hydrolysis time is controlled at 60min to obtain active white Carbon black and fluosilicic acid solution, after suction filtration, the vacuum degree is controlled at 0.06MPa, the amount of washing and washing water is controlled at 15% of the filter cake, drying, and the drying temperature is controlled at 110°C, and the activated white carbon black product...

Embodiment 3

[0030] Under the temperature condition of 160°C, add 1000g of sodium fluorosilicate and an equal amount of concentrated sulfuric acid into the reactor for reaction to obtain hydrogen fluoride and silicon tetrafluoride gas, and sodium sulfate by-product. The anhydrous hydrogen fluoride product is obtained after dehydration, dust removal and pressure swing adsorption separation of the two gases. Silicon tetrafluoride gas is passed into water, the molar ratio of silicon tetrafluoride and water is controlled at 3:4, the pressure of silicon tetrafluoride gas is controlled at 900mbar, the hydrolysis temperature is controlled at 60°C, and the hydrolysis time is controlled at 120min to obtain active white Carbon black and fluosilicic acid solution, after suction filtration, the vacuum degree is controlled at 0.1MPa, the amount of washing and washing water is controlled at 20% of the filter cake, drying, and the drying temperature is controlled at 110°C, and dried for 2 hours to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com