Device for preparing fine crystal powder based on electrostatic spraying, and using method thereof

A technology for powder preparation and electrostatic spraying, applied in the field of powder metallurgy, can solve the problems of difficulty in obtaining powder materials with submicron or even nanometer size, difficulty in obtaining uniform size products, and increase in powder production cost, and achieve convenient powder morphology and display. The effect of microstructure, fine grain size and high purity, good prospects for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

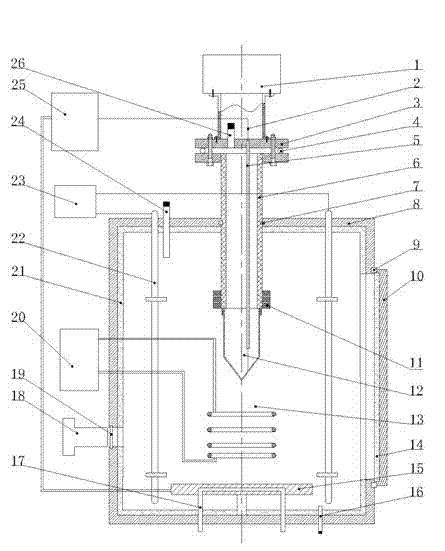

[0033] A device for preparing fine-grained powder based on electrostatic spraying and a method for using the same. Such as figure 1 As shown, the device includes a lifting mechanism 1 , a hollow pole 6 , a quartz crucible 12 , an induction heating coil 13 , a water-cooled receiving copper plate 15 , a furnace body 8 and an infrared thermometer 18 .

[0034] The center of the top of the furnace body 8 is provided with a lifting hole, the hollow strut 6 passes through the lifting hole, the lower end of the hollow strut 6 is connected to the upper end of the quartz crucible 12 through a variable diameter sealing joint 11, and the upper end of the hollow strut 6 passes through the flange 3 is connected with the lifting mechanism 1, and the lifting mechanism 1 is located directly above the center of the top of the furnace body 8.

[0035] A high-temperature-resistant protective layer 21 is built close to the inner wall of the furnace body 8, and 4-8 heating elements 22 are vertica...

Embodiment 2

[0052] A device for preparing fine-grained powder based on electrostatic spraying and a method for using the same. This embodiment is the same as embodiment 1 except that the heating element 22 is 5-8 and the argon gas is nitrogen gas.

[0053] This specific embodiment is compared with the prior art. Has the following advantages:

[0054] (1) This specific embodiment does not need to add any medium during the powder making process, has no pollution, has high powder purity, and is suitable for producing high-purity powder.

[0055] (2) By adjusting the size of the high-voltage electrostatic field, this specific embodiment can change the size of the dispersion force on the molten metal droplets, and can control the degree to which the molten metal is evenly dispersed during the spraying process, effectively controlling the metal powder. particle size, particle size distribution and morphology.

[0056] (3) This specific embodiment adopts rapid solidification technology, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com