Polymer micelle modified by nano copper oxide and preparation method of polymer micelle

A technology of nano-copper oxide and polymer glue, which is applied in chemical instruments and methods, chemical/physical processes, colloid chemistry, etc., can solve problems such as unfavorable large-scale industrial production, easy agglomeration of nano-copper oxide, and affecting performance. Achieving good biodegradability, avoiding the problem of organic solvent solvent residue, and preventing the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

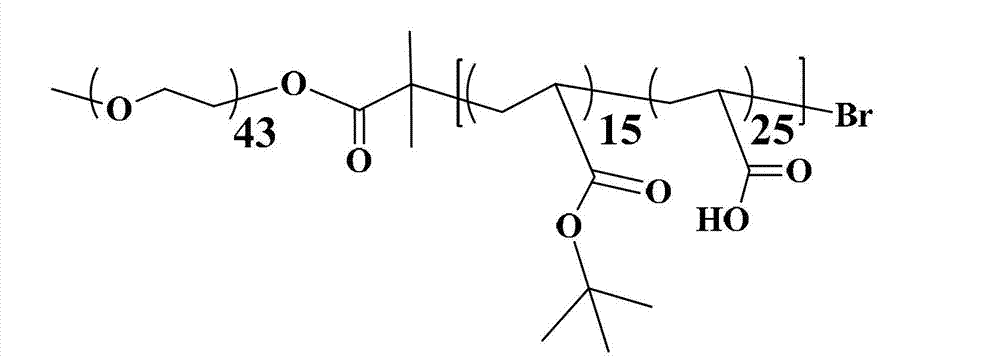

[0055] (1) Macromolecular initiator PEO 43 -Synthesis of Br

[0056] Azeotropically distill 10g of flaky PEO and 250mL of toluene to remove excess water, lower the temperature of the system to room temperature, change to an ice-water bath, add 2mL of triethylamine, 1.9mL of 2-bromoisobutyryl bromide in 20mL of toluene (The molar ratio of polyoxyethylene, 2-bromoisobutyryl bromide and triethylamine is 1:3:2.8), react for 20h, filter, extract, collect the organic phase, dry, filter, precipitate, suction filter, vacuum dry , to get the white powdery macromolecular initiator PEO 43 -Br.

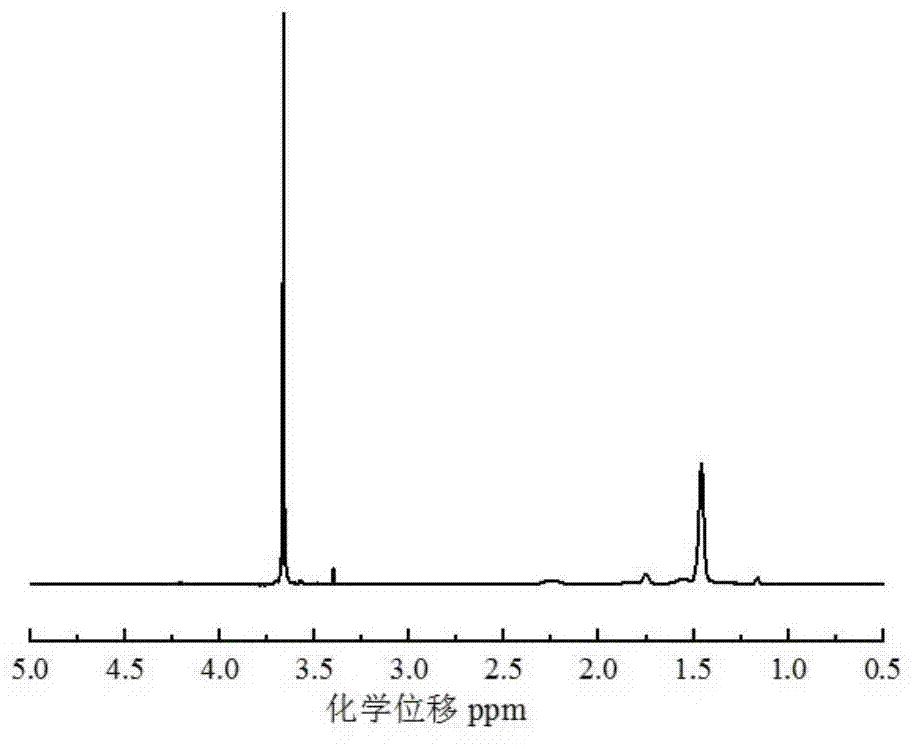

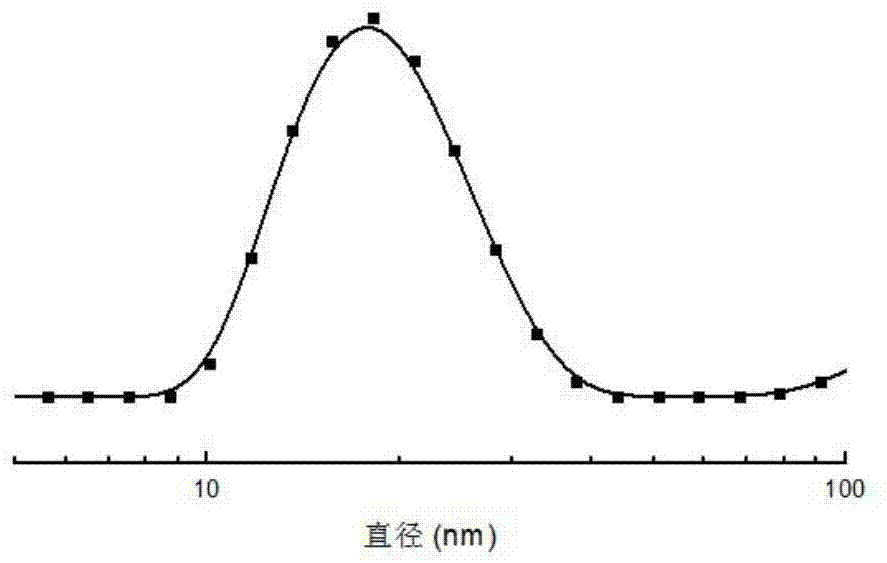

[0057] (2) ATRP synthetic polymer

[0058] 0.5g of macroinitiator PEO 43 -Br, 0.035g of catalyst cuprous bromide (CuBr), 0.040g of ligand PMDETA (the molar ratio of macroinitiator PEO-Br, ligand PMDETA, and catalyst is 1:1:1), 3.16 g tert-butyl acrylate (tBA) and 2mL methanol solvent were added to a 50mL round bottom flask (in which PEO 43 The molar ratio of tert-butyl acrylate to tert-buty...

Embodiment 2

[0067] (1) Macromolecular initiator PEO 43 -Synthesis of Br

[0068] Azeotropically distill 10g of flaky PEO and 250mL of toluene to remove excess water, lower the temperature of the system to room temperature, change to an ice-water bath, add 2mL of triethylamine, 1.9mL of 2-bromoisobutyryl bromide in 20mL of toluene (The molar ratio of polyoxyethylene, 2-bromoisobutyryl bromide and triethylamine is 1:3:2.8), react for 20h, filter, extract, collect the organic phase, dry, filter, precipitate, suction filter, vacuum dry , to get the white powdery macromolecular initiator PEO 43 -Br.

[0069] (2) ATRP synthetic polymer

[0070] 0.5g of macroinitiator PEO 43 -Br, 0.035g of catalyst cuprous bromide (CuBr), 0.040g of ligand PMDETA (the molar ratio of macroinitiator PEO-Br, ligand PMDETA, and catalyst is 1:1:1), 4.5 g tert-butyl acrylate (tBA) and 2mL methanol solvent were added to a 50mL round bottom flask (in which PEO 43 The molar ratio of tert-butyl acrylate to tert-butyl...

Embodiment 3

[0078] (1) Macromolecular initiator PEO 43 -Synthesis of Br

[0079] Azeotropically distill 10g of flaky PEO and 250mL of toluene to remove excess water, lower the temperature of the system to room temperature, change to an ice-water bath, add 2mL of triethylamine, 1.9mL of 2-bromoisobutyryl bromide in 20mL of toluene (The molar ratio of polyoxyethylene, 2-bromoisobutyryl bromide and triethylamine is 1:3:2.8), react for 30h, filter, extract, collect the organic phase, dry, filter, precipitate, suction filter, vacuum dry , to get the white powdery macromolecular initiator PEO 43 -Br.

[0080] (2) ATRP synthetic polymer

[0081] 0.5g of macroinitiator PEO 43 -Br, 0.035g of catalyst cuprous bromide (CuBr), 0.040g of ligand PMDETA (the molar ratio of macroinitiator PEO-Br, ligand PMDETA, and catalyst is 1:1:1), 5.3 g tert-butyl acrylate (tBA) and 2mL methanol solvent were added to a 50mL round bottom flask (in which PEO 43 The molar ratio of tert-butyl acrylate to tert-butyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com