A pulverized coal granulation method and equipment for lignite

A technology of granulation and pulverized coal, which is applied in the field of coal processing and utilization, can solve the problems of not meeting the requirements of forming, hindering processing and storage, and expensive equipment, and achieves good forming strength, significant moisture reduction, and low power consumption. low volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

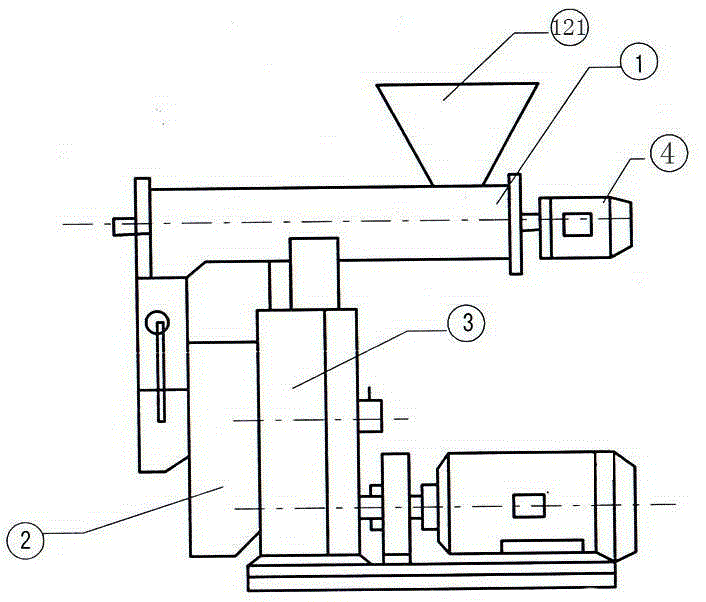

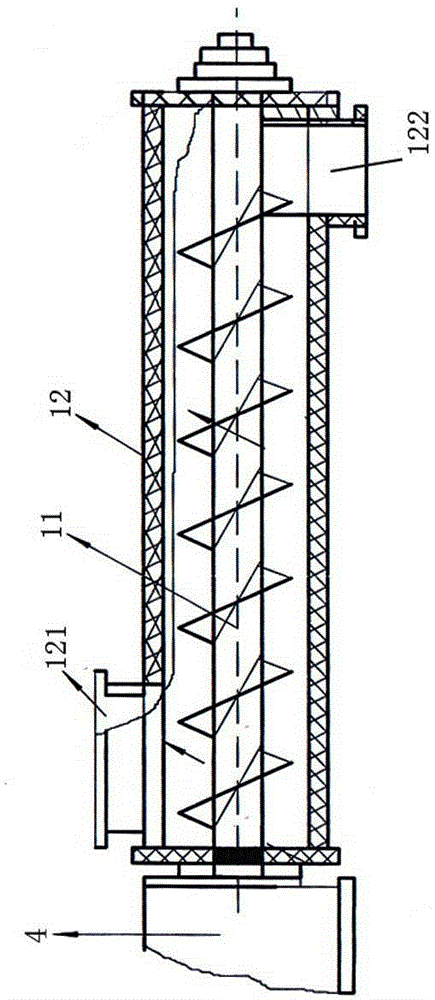

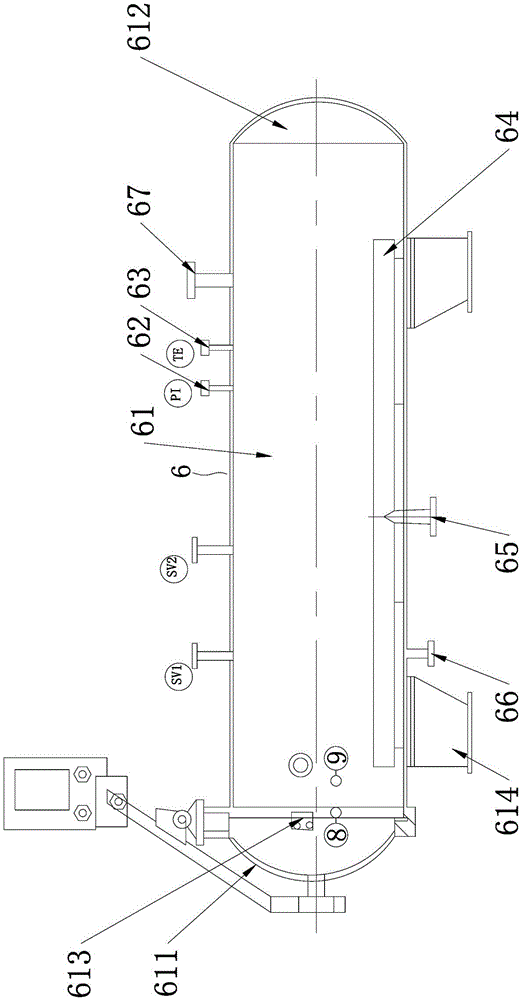

[0033] A pulverized coal granulation method of lignite, the granulation steps are as follows:

[0034] Step 1, raw material preparation:

[0035] Sieve and crush the pulverized coal that needs to be granulated to a particle size of less than 4mm. The finer the fineness, the higher the granulation molding rate and the better the molding strength, but the powder finer than 0.1mm is the same There is no difference in molding rate and molding strength. Therefore, the particle size of pulverized coal after screening and crushing can be controlled within 4mm. The moisture content of the pulverized coal that needs to be granulated should be controlled at a moisture content of 20% to 45%. The granulation effect with a moisture content of 30% to 35% is the best, the strength is the best, the molding rate is the highest, and the operation of the granulation equipment involved is the fastest. Stable, low power consumption, only 3-10 kilowatt-hours per ton, minimal wear and tear on gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com