Insulated gate bipolar transistor (IGBT) device and manufacture process method thereof

A manufacturing process and device technology, which is applied in the field of IGBT devices and its manufacturing process, can solve the problems of expensive equipment, unreachable injection depth, high energy requirement, etc., achieve the optimization of withstand voltage and conduction voltage drop, and improve the safe working area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056]In order to enable your examiners to have a further understanding and understanding of the purpose, features and effects of the present invention, the following detailed description is as follows with the accompanying drawings.

[0057] The steps of the first embodiment of the method of the present invention include:

[0058] Step 1. Prepare an N-type region of molten silicon as the N-base region 101, such as Figure 1a shown. The thickness of the molten silicon in the N-type region may be 725 microns.

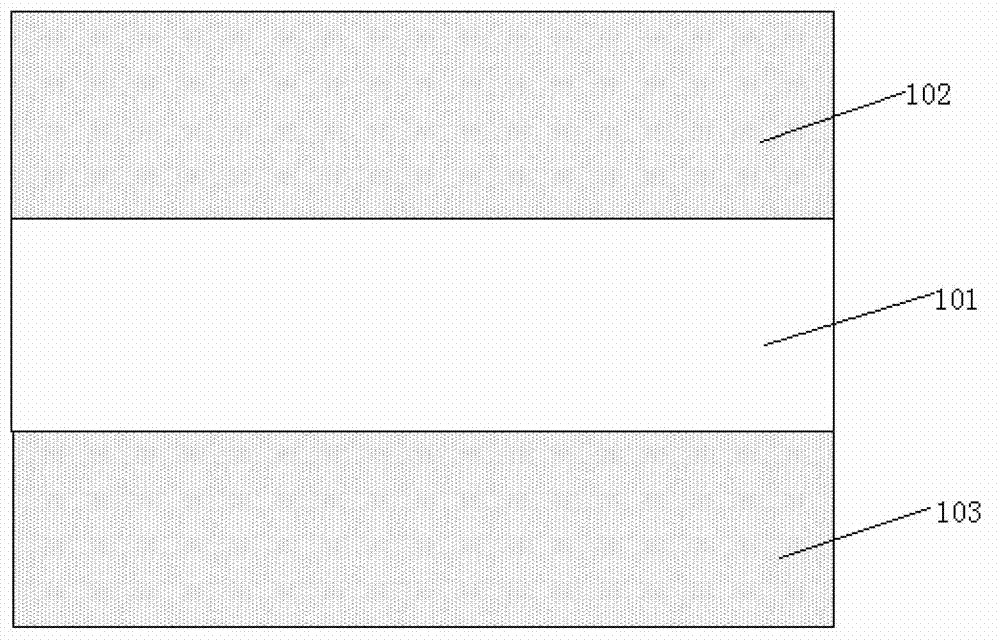

[0059] Step 2. Perform double-sided high-temperature N-type impurity diffusion on the N-base region 101. A high-temperature phosphorus doping process (POCL3 process) can be used to form a certain depth of double-sided N-type doped regions, including the front N-type doped region 102 and N-type doped region 103 on the back; as Figure 1b shown. The depth of one side is usually 90-110 microns for 3300V IGBT; 50-70 microns for 4500V IGBT; 10-30 microns for 6500VIGBT.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com