Method for synthesizing tellurium molybdate magnesium single crystal micro powder by using supercritical water system

A supercritical water and powder technology, applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., to achieve the effect of simplifying synthesis steps, simple reaction equipment, and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

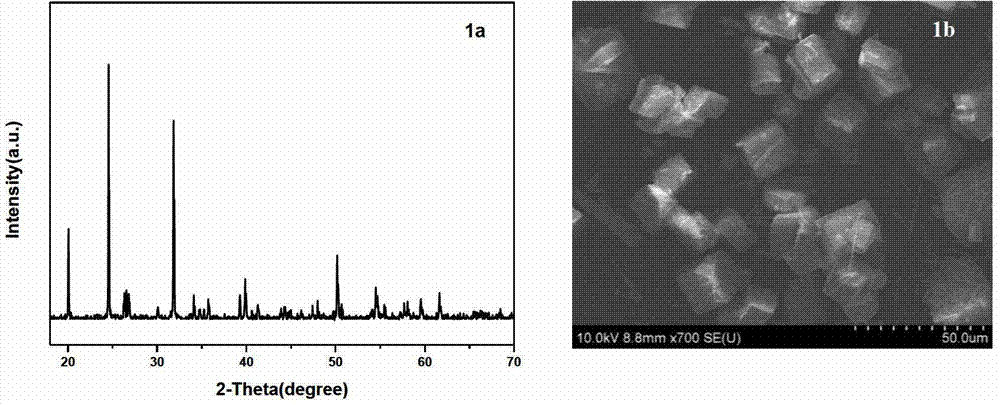

Embodiment 1

[0027] 1. Ingredients

[0028] Weigh 0.1200 g of magnesium oxide, 0.4318 g of molybdenum trioxide and 0.4788 g of tellurium dioxide and disperse them into 50 ml of ultrapure water. It was then sealed into a reaction vessel (capacity 100 ml).

[0029] 2. Constant temperature reaction

[0030] Put the sealed reaction kettle into a muffle furnace to heat, so that the internal temperature of the reaction vessel is 380°C, the pressure in the reaction vessel is 24±0.2MPa, and the reaction is performed at constant temperature for 1 hour.

[0031] 3. Cooling

[0032] After the constant temperature reaction is over, turn off the power directly to cool down the furnace, let the reaction kettle cool down to room temperature (20-25°C) naturally, and take the reaction kettle out of the muffle furnace.

[0033] 4. Washing

[0034] The product was taken out from the reaction kettle, filtered through a vacuum filtration device, and washed at least three times with deionized water to obtai...

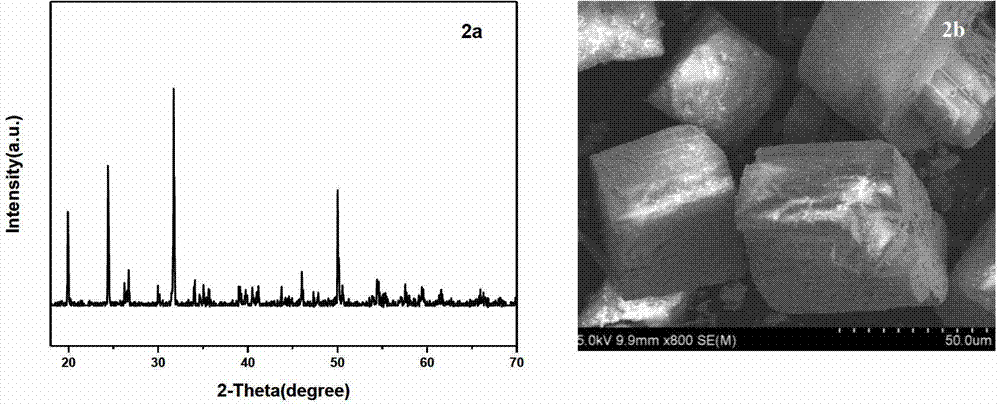

Embodiment 2

[0039] 1. Ingredients

[0040] Weigh 0.1200 g of magnesium oxide, 0.4318 g of molybdenum trioxide and 0.4788 g of tellurium dioxide and disperse them into 50 ml of ultrapure water. It was then sealed into a reaction vessel (capacity 100 ml).

[0041] 2. Constant temperature reaction

[0042] Put the sealed reaction kettle into a muffle furnace and heat it so that the internal temperature of the reaction vessel is 380° C., the pressure in the reaction vessel is 23-24 MPa, and the reaction is carried out at constant temperature for 2 hours.

[0043] 3. Cooling

[0044] After the constant temperature reaction is over, turn off the power to cool down the muffle furnace, let the reaction kettle cool down to room temperature (20-25°C) naturally, and take the reaction kettle out of the muffle furnace.

[0045] 4. Washing

[0046] The product was taken out from the reaction kettle, filtered through a vacuum filtration device, and washed at least three times with ethanol to obtain ...

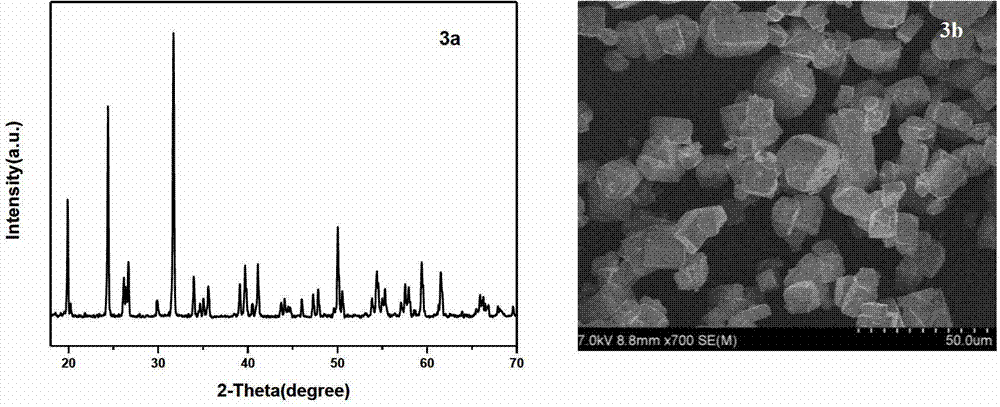

Embodiment 3

[0051] 1. Ingredients

[0052] Weigh 0.1200 g of magnesium oxide, 0.4318 g of molybdenum trioxide and 0.4788 g of tellurium dioxide and disperse them into 50 ml of ultrapure water. It was then sealed into a reaction vessel (capacity 100 ml).

[0053] 2. Constant temperature reaction

[0054] Put the sealed reaction kettle into a resistance furnace and heat it so that the internal temperature of the reaction vessel is 380° C. and the pressure in the reaction vessel is 24-25 MPa, and the reaction is performed at a constant temperature for 4 hours.

[0055] 3. Cooling

[0056] After the constant temperature reaction is over, the reactor is naturally cooled to room temperature (20-25°C), and the reactor is taken out from the resistance furnace.

[0057] 4. Washing

[0058] Take out the product from the reaction kettle, filter the product through a vacuum filtration device (the pore size of the filter membrane is 0.025-0.5 microns), wash with deionized water until the pH of the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com