Control system for coal mine underground water-jet cutting machine

A technology of control system and water cutting machine, applied in the direction of manufacturing tools, special mining, shearing devices, etc., can solve the problems of difficult materials that cannot be transported, cutting and processing, etc., and achieve the effects of high work efficiency, convenient portability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

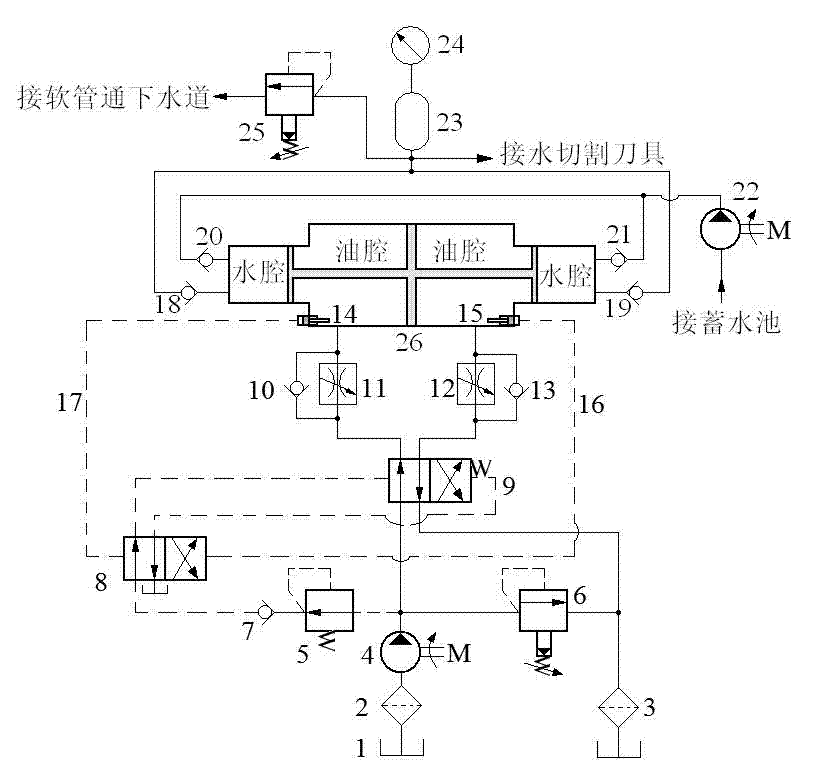

[0011] Such as figure 1 As shown, the water cutting machine includes a water cutting tool and a control system, and the water cutting tool is connected to the control system to form a water cutting machine as a whole; it is characterized in that: the control system includes an oil tank 1, a first oil filter 2, a second Oil filter 3, hydraulic pump 4, pressure reducing valve 5, pilot relief valve 6, first one-way valve 7, first hydraulic control reversing valve 8, second hydraulic control reversing valve 9, second one-way Valve 10, first speed regulating valve 11, second speed regulating valve 12, third one-way valve 13, first ejector plunger valve 14, second ejector plunger valve 15, first hydraulic oil pipe 16, second Hydraulic oil pipe 17, the fourth one-way valve 18, the fifth one-way valve 19, the sixth one-way valve 20, the seventh one-way valve 21, the water pump 22, the accumulator 23 and the double-acting booster cylinder 26, and the oil tank 1 is The first oil filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com