Novel N-methyl aniline catalyst synthesized through chromium-free gas phase method

A methylaniline and catalyst technology, applied in the field of new catalysts, can solve the problems of chromium pollution, chromium pollution of downstream products, etc., and achieve the effect of high conversion rate, selectivity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: 365g of copper nitrate, 392g of zinc nitrate, 47.8g of magnesium nitrate, 21.3g of barium nitrate and 6.3g of cerium nitrate were dissolved in 1L of water, heated to 50°C, 650g of sodium bicarbonate was dissolved in 3L of water, and heated to 70°C, then slowly drop the sodium bicarbonate solution into the mixed solution of nitrate, and stir rapidly at the same time until pH = 7.5. Raise the temperature to 80°C and stir for 1 hour, then filter and wash, and dry the solid material at 120°C 6 hours, bake at 300°C for 2 hours, then add 2% graphite and 4% water and mix evenly, and press it into a tablet of Ф5×(4.5-5.5) mm with a tablet machine. Points (calculated as oxides) 48% copper, 43% zinc, 3% magnesium, 5% barium, 1.% cerium.

Embodiment 2

[0019] Dissolve 350g of copper nitrate, 338g of zinc nitrate, 143g of magnesium nitrate, 27.7g of barium nitrate and 9.5g of cerium nitrate in 1L of water, heat to 50°C, dissolve 500g of sodium carbonate in 3L of water, and heat to 70°C, then dissolve the sodium carbonate Slowly add dropwise to the mixed solution of nitrate, and stir rapidly at the same time until pH = 7.5. Heat up to 80°C and stir for 1 hour, then filter and wash, dry the solid material at 120°C for 6 hours, and roast at 300°C for 2 hours hours, then add 1% graphite and 4% water and mix evenly, and press it into a tablet of Ф5×(4.5-5.5) mm with a tablet machine, so that the components in the catalyst (calculated as oxides) are 46% Copper, 37% zinc, 9% magnesium, 6.5% barium, 1.5% cerium.

Embodiment 3

[0020] Example 3: Dissolve 289g copper nitrate, 401g zinc nitrate, 95.5g magnesium nitrate, 44.7g barium nitrate, 9.5g cerium nitrate in 1L water, heat to 50°C, dissolve 500g sodium carbonate in 3L water, and heat to 70°C , then slowly add the sodium carbonate solution dropwise into the mixed solution of nitrates, and at the same time stir rapidly until the pH=7.5. Raise the temperature to 80°C and stir for 1 hour, then filter and wash, and dry the solid material at 120°C for 6 hours. Calcined at 300°C for 2 hours, then added graphite and 2% water, mixed evenly, and pressed into a tablet of Ф5×(4.5-5.5) mm with a tablet machine, the components in the catalyst (calculated as oxides) ) 38% copper, 44% zinc, 6% magnesium, 10.5% barium, 1.5% cerium.

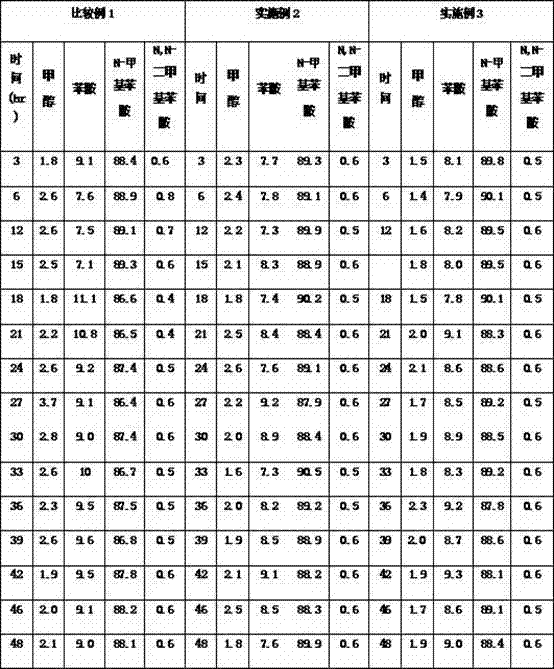

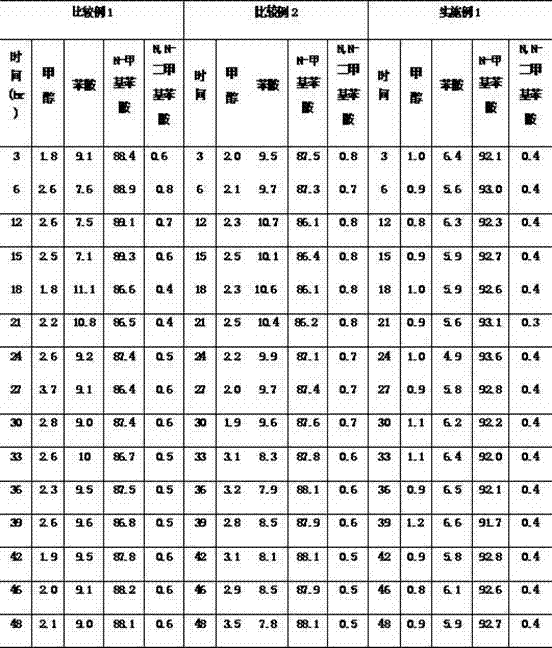

[0021] The performance comparison of embodiment catalyst and comparative example catalyst:

[0022] Evaluation method: The laboratory device completely simulates the large-scale industrial production device. The reactor is a Ф32 sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com