Method for distinguishing welding bead based on colour information

A technology of welding bead identification and color information, applied in the field of welding bead identification, can solve the problems that the structured light method is difficult to locate the edge of the weld, cannot reflect the position of its boundary, and it is difficult to obtain the position of the edge of the weld, and achieves short time consumption. , improve the accuracy, the effect of accurate classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

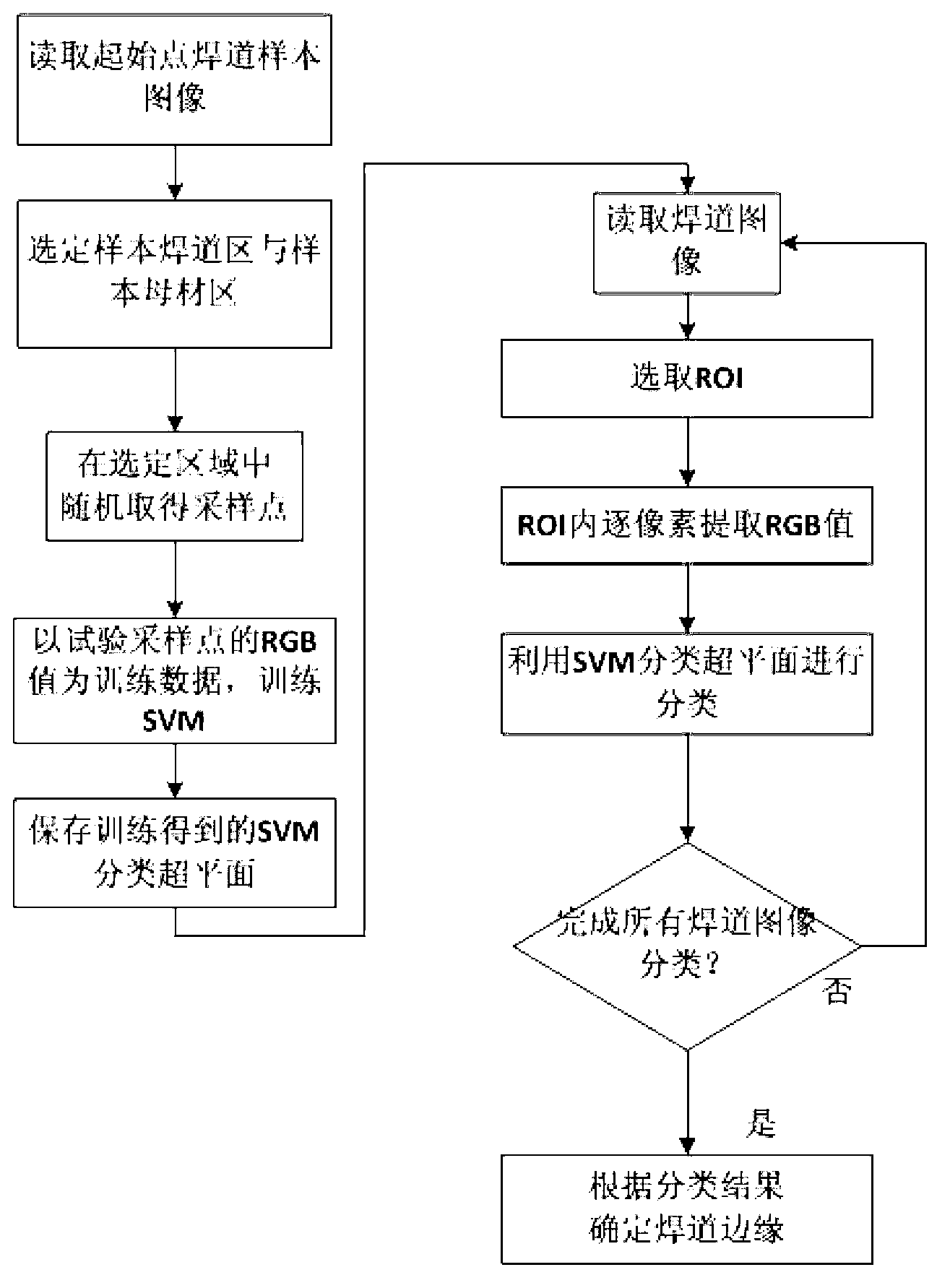

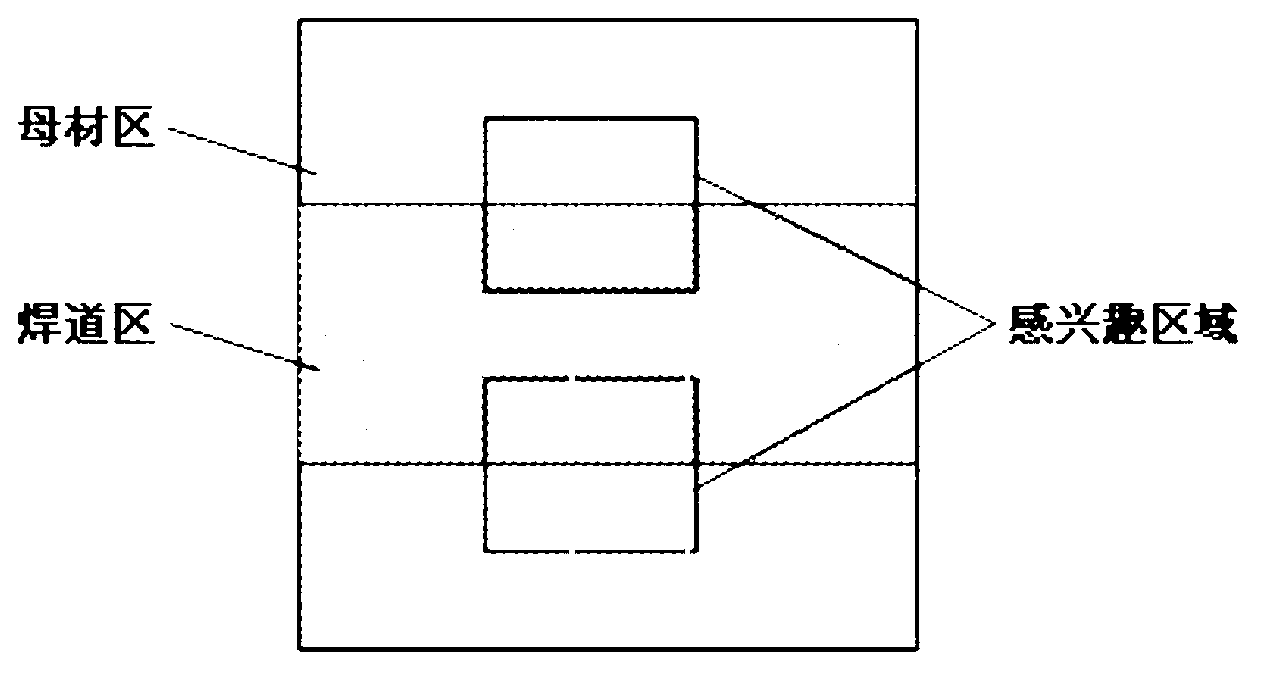

[0018] like figure 1 As shown, the method for welding bead recognition based on color information of the present invention comprises the following steps:

[0019] 1. Obtain training images, and collect training data for support vector machine training to obtain a classification hyperplane, which includes the following steps:

[0020] 1) Use the existing color industrial camera to take a sample image of the weld bead at the starting point of the weld bead to be welded or to be inspected. The weld bead sample image obtained includes the weld bead area, the edge area of the weld bead and the Part of the parent material area.

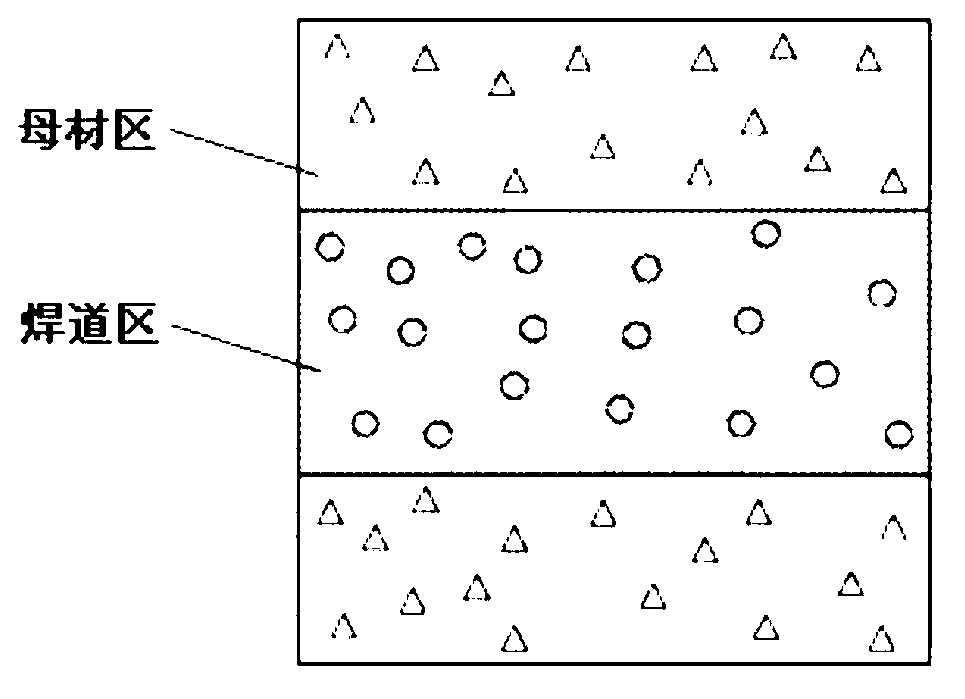

[0021] 2) Take the weld bead sample image obtained as the training image, and select the sample weld bead area and the sample base metal area in the training image, wherein the sample weld bead area includes as large a weld bead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com