Wood carbon fiber precursor and preparation method thereof

A carbon fiber precursor and wood technology, which is applied in the field of wood carbon fiber precursor and the preparation of the carbon fiber precursor can solve the problems of environmental hazards, volatile, highly toxic, etc., and achieve the effect of low residue rate and promotion of liquefaction reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

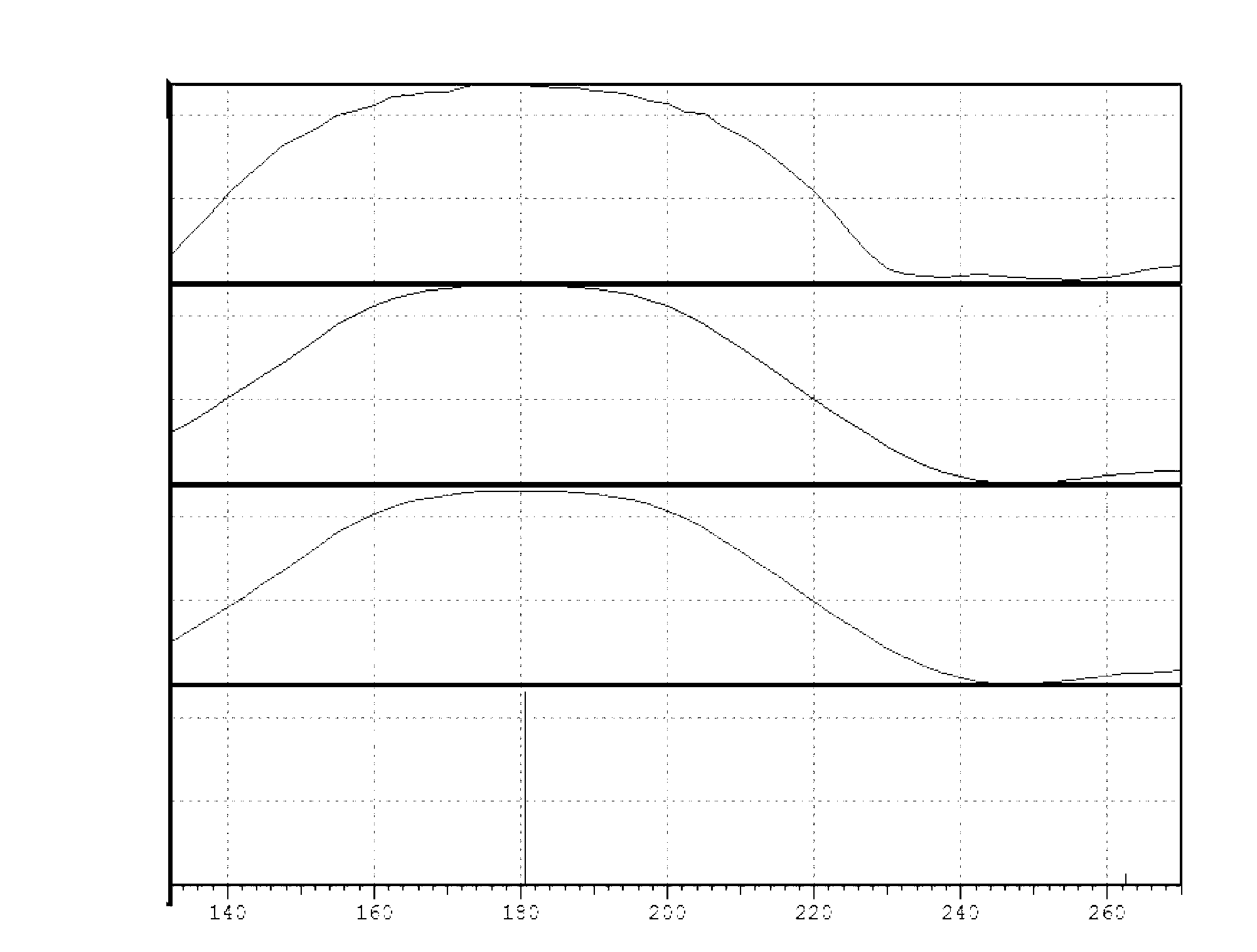

Image

Examples

Embodiment 1

[0048] The wood is pulverized into 80-mesh (mesh aperture 0.18mm) powder with a pulverizer, and then the wood powder is mixed with 4 times the weight of wood powder phenol and catalyst sulfuric acid (the mass fraction of sulfuric acid is 36%, and the addition amount is 1% of the weight of phenol. 7%) into a three-necked glass bottle, placed in an oil bath preheated to 140°C, installed a condenser, and started the stirring device (speed 1058rpm) to liquefy wood. The liquefaction time was 2.5 hours to obtain wood liquefaction .

[0049] Add the wood liquefaction and hexamethylenetetramine with 5% weight of the liquefaction into the spinning machine, heat it from 35 °C to the synthesis temperature of 110 °C at a constant speed for 50 min, keep it warm for 10 min, and heat it under N 2 The initial carbon fiber was spun at 110°C under pressure. The spinning process conditions were: the diameter of the spinneret hole was 1.5mm (single hole), the speed of the take-up roll was 100r / mi...

Embodiment 2

[0054] Grind the wood into a 60-mesh powder with a pulverizer, then add the wood powder, 5 times the weight of the wood powder, and catalyst sulfuric acid (the mass fraction of sulfuric acid is 36%, and the amount added is 8% of the weight of the phenol) into a three-necked glass bottle placed in an oil bath preheated to 150°C, installed a condenser, and started the stirring device (speed 1058rpm) to liquefy wood for 2 hours to obtain wood liquefaction.

[0055] Add the wood liquefaction and hexamethylenetetramine with 8% weight of the liquefaction into the spinning machine, heat it from 35°C to the synthesis temperature of 120°C at a constant speed for 70 minutes, keep it warm for 15 minutes, and spin it at 120°C under N2 pressure. The initial carbon fiber, the spinning process conditions are: the diameter of the spinneret hole is 1.2mm (single hole), the speed of the take-up roll is 150r / min, and the distance from the spinneret hole to the take-up roll is 50mm.

[0056] Put ...

Embodiment 3

[0060] Grind the wood into 40-mesh powder with a pulverizer, and then add the wood powder, phenol and catalyst sulfuric acid (the mass fraction of sulfuric acid is 36% and the addition amount is 9% of the weight of phenol) to the three-necked glass bottle placed in an oil bath preheated to 160°C, installed a condenser, and started the stirring device (speed 1058rpm) to liquefy wood for 3 hours to obtain wood liquefaction.

[0061] Add wood liquefaction and glyoxal with 7% weight of liquefaction into the spinning machine, heat from 35°C to synthesis temperature 130°C at a constant speed for 60 minutes, keep warm for 10 minutes, and spin the initial carbon fiber at 130°C under N2 pressure , The spinning process conditions are: the diameter of the spinneret hole is 0.8mm (single hole), the speed of the take-up roll is 200r / min, and the distance from the spinneret hole to the take-up roll is 50mm.

[0062] Put the initial fiber into the curing pool, add 18.5% formaldehyde and 18.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

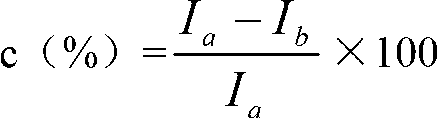

| crystallinity | aaaaa | aaaaa |

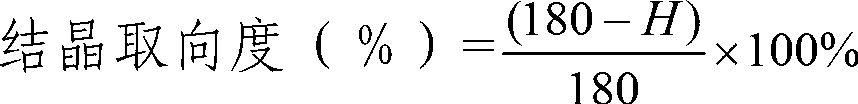

| Orientation degree | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com