Maltotriose preparation method with starch as raw material and special fungal alpha-amylase thereof

A maltotriose and amylase technology is applied in the field of the preparation of maltotriose, the preparation method of maltotriose and its special fungal alpha-amylase, and achieves the effects of low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

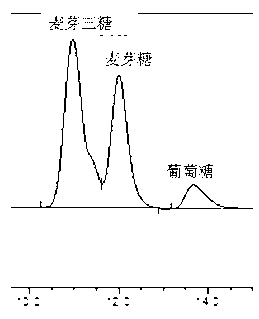

[0068] Weigh 10 g of cornstarch, use tap water to prepare starch milk with a concentration not higher than 5%, heat it to 80°C, and keep it warm for 10 minutes. The above starch mash was cooled to 45 °C, and 5% hydrochloric acid solution was added to adjust the pH to 4.5, and SfA was added in an amount of 0.15 U / g dry starch, and kept for 6 hours. like Figure 1~3 Shown is the analysis result of sugar in the obtained starch hydrolyzate, wherein the obtained maltotriose accounts for about 52% of the total sugar concentration, and maltose accounts for about 39%. Similar results were obtained using potato starch, sweet potato starch, glutinous rice starch and wheat starch as raw materials, and the content of maltotriose in the obtained hydrolyzate was between 46% and 55% of the total sugar.

[0069] Embodiment 2: Extraction of maltotriose

Embodiment 2

[0070] (1) Fill the chromatographic glass column with activated carbon, and add ordinary tap water from the top to submerge the activated carbon. Add the syrup obtained in Example 1 from the top of the chromatographic column, collect the liquid flowing out from the bottom of the chromatographic column, and detect the reducing sugar content in the effluent liquid. When the reducing sugar content reaches 0.2% in the liquid, it shows that the adsorption capacity of activated carbon has reached saturation. Stop Add sugar solution. Vent the liquid in the activated carbon column. The effluent solution is mainly glucose.

[0071] (2) Close the outlet below the activated carbon column, add 4.5%-5.0% alcohol solution from the upper part of the activated carbon column, until the alcohol solution submerges the activated carbon, and equilibrate for 30 min. Open the outlet below the activated carbon column to release the alcohol solution, which is mainly glucose and maltose.

[0072] (3...

Embodiment 3

[0075] According to the method introduced in the literature [Zhou Xiaoling, Shen Wei, Rao Zhiming, Wang Zhengxiang, Zhuge Jian. A method for rapid extraction of fungal chromosomal DNA. Microbiology Bulletin, 2004, 31(4): 89-92] to extract button capsule and compound membrane Saccharomyces ( Saccharomycopsis fibuligera ) CICIM Y1037 chromosomal DNA.

[0076] According to the α-amylase gene sequence [Itoh T, Yamashita I and Fukui S. Nucleotide sequence of the alpha-amylase gene (ALP1) in the yeast published by Itoh et al. Saccharomycopsis fibuligera . FEBS Lett, 1987, 219(2): 339-342.] Designing primers:

[0077] 5'-AATTACCGTC TAGACAACCA GTGACTCTAT TC-3' (SEQ ID NO: 2),

[0078] 5'-AATTACCGTC TAGATTATGA ACAAATGTCA GAAG-3' (SEQ ID NO: 3)

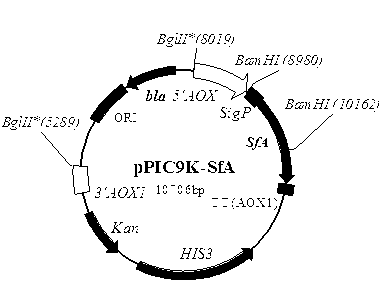

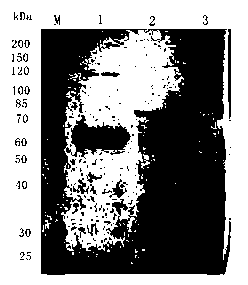

[0079] Using the above-mentioned extracted chromosomal DNA of S. forticulata as a template, using the above-mentioned primers, PCR amplification was performed with Ex Taq enzyme to obtain the mature peptide coding region of the α-amylase ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com