Acidation blocking remover and preparation method thereof

A plugging agent and solvent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor retarding effect, excessive consumption, and weakened retarding effect of authigenic acid, and achieve good complexation performance, The effect of slowing down the reaction speed and good retarding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

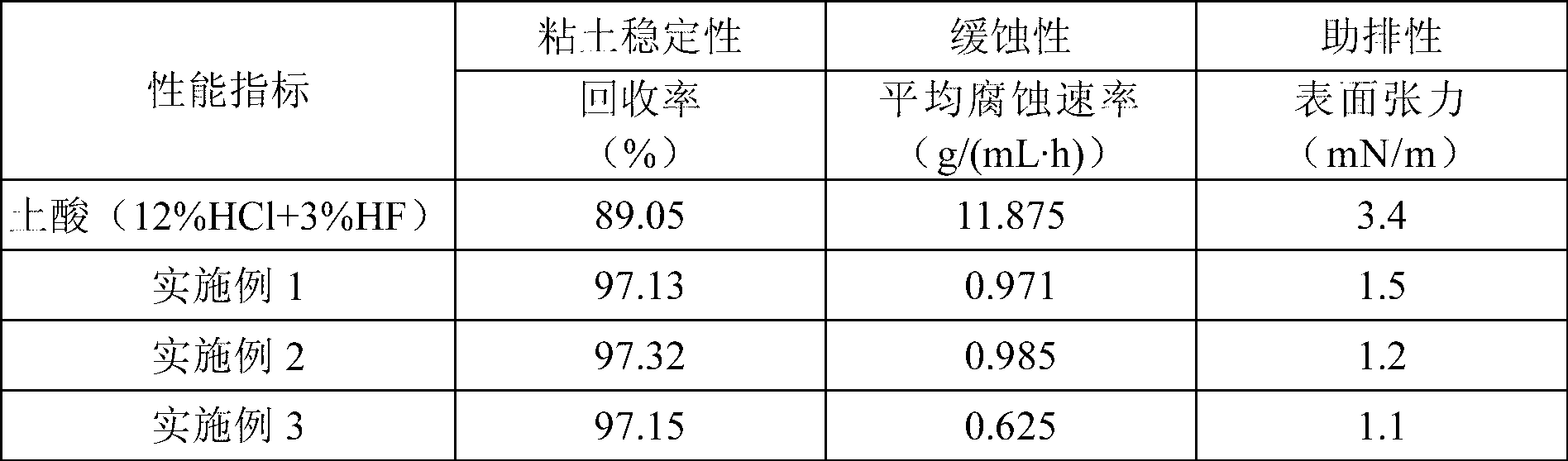

Examples

Embodiment 1

[0034] This embodiment provides an acidifying plugging remover, which consists of the following components by weight percentage: main acid solution, 20%, corrosion inhibitor BSA-602, 0.1%, clay stabilizer BSA-101, 3%, auxiliary Discharge agent EL-11, 0.5%, demulsifier YBP-1, 0.1%, and the balance is water.

[0035] The acidifying plug-removing agent is prepared through the following steps:

[0036] (1) Add 5.0mL phosphorus trichloride, 4.5mL acetone, and 25.0mL glacial acetic acid successively in a dry three-necked flask with a reflux device, stir the solution continuously at room temperature with a magnetic stirrer, and react for 5 hours until the solution becomes clear, to obtain polymerized monomers;

[0037] (2) Dissolve 10 mL of polymerized monomer in 10 mL of distilled water, then add 5 mL of acrylic acid, and stir thoroughly to obtain a mixture;

[0038](3) Get 0.1g of ammonium persulfate and dissolve it in 5mL of distilled water, and add it to the mixture obtained in...

Embodiment 2

[0042] This embodiment provides an acidifying plugging remover, which consists of the following components by weight percentage: main acid solution, 20%, corrosion inhibitor BSA-602, 0.1%, clay stabilizer BSA-101, 3%, auxiliary Discharge agent EL-11, 0.5%, demulsifier YBP-1, 0.1%, and the balance is water.

[0043] The acidifying plug-removing agent is prepared through the following steps:

[0044] (1) Add 5.9mL phosphoric acid, 9.5mL methyl ethyl ketone, and 38mL lactic acid successively into a dry three-necked flask with a reflux device, stir the solution continuously at room temperature with a magnetic stirrer, react for 5 hours until the solution becomes clear, and obtain the polymerized monomer ;

[0045] (2) Dissolve 15 mL of polymerized monomer in 15 mL of distilled water, then add 15 mL of crotonic acid, and stir thoroughly to obtain a mixture;

[0046] (3) Get 0.1g of benzoyl peroxide and dissolve it in 15mL of distilled water, and add it to the mixture obtained in ...

Embodiment 3

[0050] This embodiment provides an acidifying plugging remover, which consists of the following components by weight percentage: main acid solution, 20%, corrosion inhibitor BSA-602, 0.2%, clay stabilizer BSA-101, 3%, auxiliary Discharge agent EL-11, 0.5%, demulsifier YBP-1, 0.1%, and the balance is water.

[0051] The acidifying plug-removing agent is prepared through the following steps:

[0052] (1) Add 10.0g of phosphorus pentasulfide, 9.8mL of dimethyl ketone, and 35mL of citric acid into a dry three-necked flask with a reflux device in sequence, and stir the solution continuously at room temperature with a magnetic stirrer, and react for 5 hours until the solution becomes clear. , to obtain polymerized monomers;

[0053] (2) Dissolve 10mL of polymerized monomer carefully in 10mL of distilled water, then add 15mL of methacrylic acid, and stir thoroughly to obtain a mixture;

[0054] (3) Dissolve 0.1g of potassium peroxide in 10mL of distilled water and add it to the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com