Flame-retardant polyester and preparation method thereof

A technology of flame-retardant polyester and polyester, which is applied in the field of flame-retardant polyester and its preparation, can solve problems such as limited application, and achieve the effect of improving flame-retardant effect and slowing down the formation of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

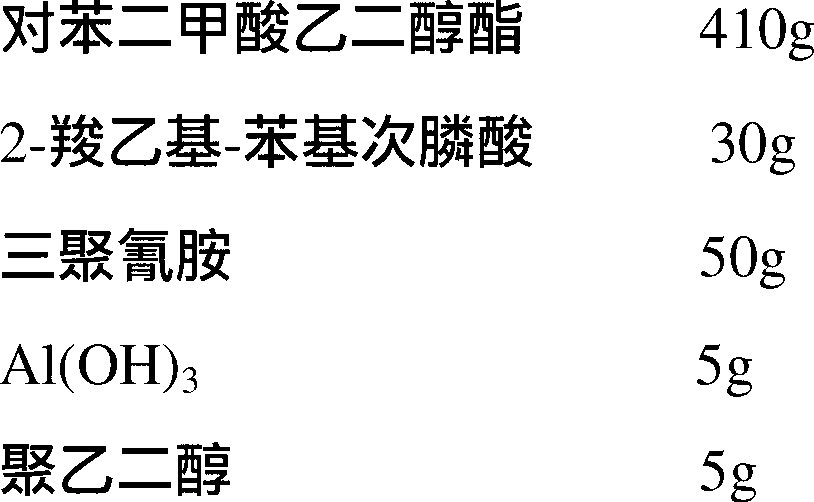

Embodiment 1

[0020]

[0021] Ethylene terephthalate adopts continuous esterification-polycondensation process to prepare polyethylene terephthalate ethylene glycol, and 2-carboxyethyl-phenylphosphinic acid and Al( OH) 3 , the preliminary polyester product was obtained. It was then melt blended with melamine using a screw extruder to prepare a flame retardant polyester for film.

[0022] Specific steps are as follows:

[0023] (1) Preparation of metal compound powder solution: Mix the metal compound powder with the carrier solution ethylene glycol in a weight ratio of 1:5, then place it in an ultrasonic machine to oscillate, control the ultrasonic power to 100W for 1 hour, and then put it into a centrifuge. Disperse for 0.5h until the dispersion is uniform, and obtain the metal compound powder solution for use;

[0024] (2) Pretreatment of phosphorus-based flame retardant: Mix the phosphorus-based flame retardant with the reaction solution ethylene glycol in a weight ratio of 1:2, and...

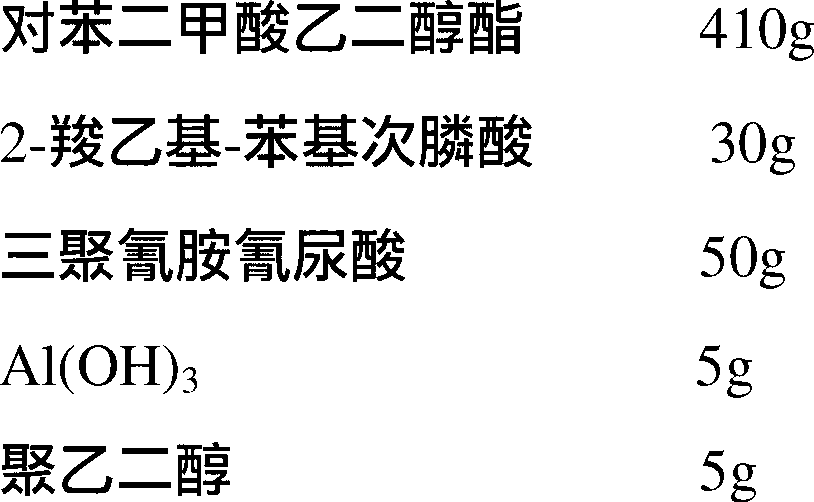

Embodiment 2

[0028]

[0029] Ethylene terephthalate adopts continuous esterification-polycondensation process to prepare polyethylene terephthalate ethylene glycol, and 2-carboxyethyl-phenylphosphinic acid and Al( OH) 3 , the preliminary polyester product was obtained. Then, it was melt-blended with melamine cyanuric acid using a screw extruder to prepare a flame-retardant polyester for film.

[0030] Specific steps are as follows:

[0031] (1) Preparation of metal compound powder solution: Mix the metal compound powder and the carrier solution in a weight ratio of 1:5 and then place it in an ultrasonic machine to oscillate, control the ultrasonic power to 100W for 1 hour, and then put it into a centrifuge to disperse for 0.5 hours To disperse uniformly, obtain metal compound powder solution for use;

[0032] (2) Pretreatment of phosphorus-based flame retardant: Mix the phosphorus-based flame retardant with the reaction solution at a weight ratio of 1:3, and react at 130 °C for 1.5 h...

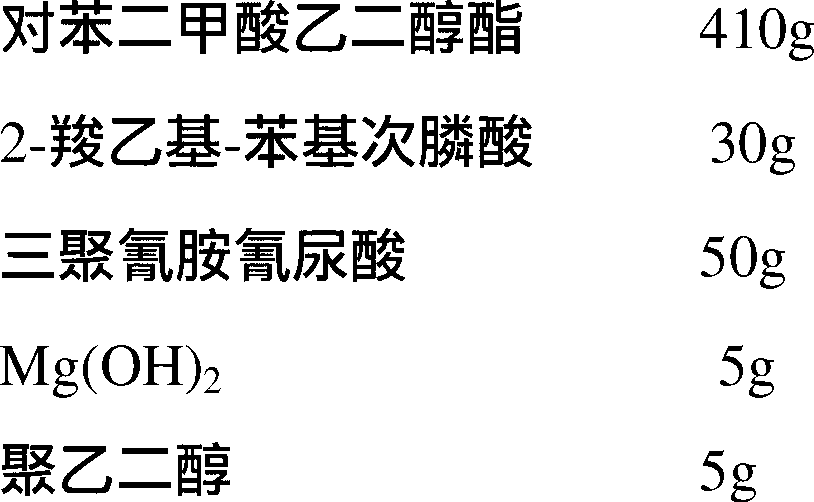

Embodiment 3

[0037]

[0038] Ethylene terephthalate adopts continuous esterification-polycondensation process to prepare polyethylene terephthalate ethylene glycol, and 2-carboxyethyl-phenylphosphinic acid and Mg( OH) 2 , the preliminary polyester product was obtained. Then, it was melt-blended with melamine cyanuric acid using a screw extruder to prepare a flame-retardant polyester for film.

[0039] Specific steps are as follows:

[0040] (1) Preparation of metal compound powder solution: Mix the metal compound powder with the carrier solution in a weight ratio of 1:3 and then place it in an ultrasonic machine to oscillate, control the ultrasonic power to 100W for 1.5h, and then put it in a centrifuge to disperse 0.5 h until the dispersion is uniform, and the metal compound powder solution is obtained for use;

[0041] (2) Pretreatment of phosphorus-based flame retardant: Mix the phosphorus-based flame retardant with the reaction solution at a weight ratio of 1:3, and react at 130 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com