Preparation method of poly(butylene succinate)/organic montmorillonite nano-composite material

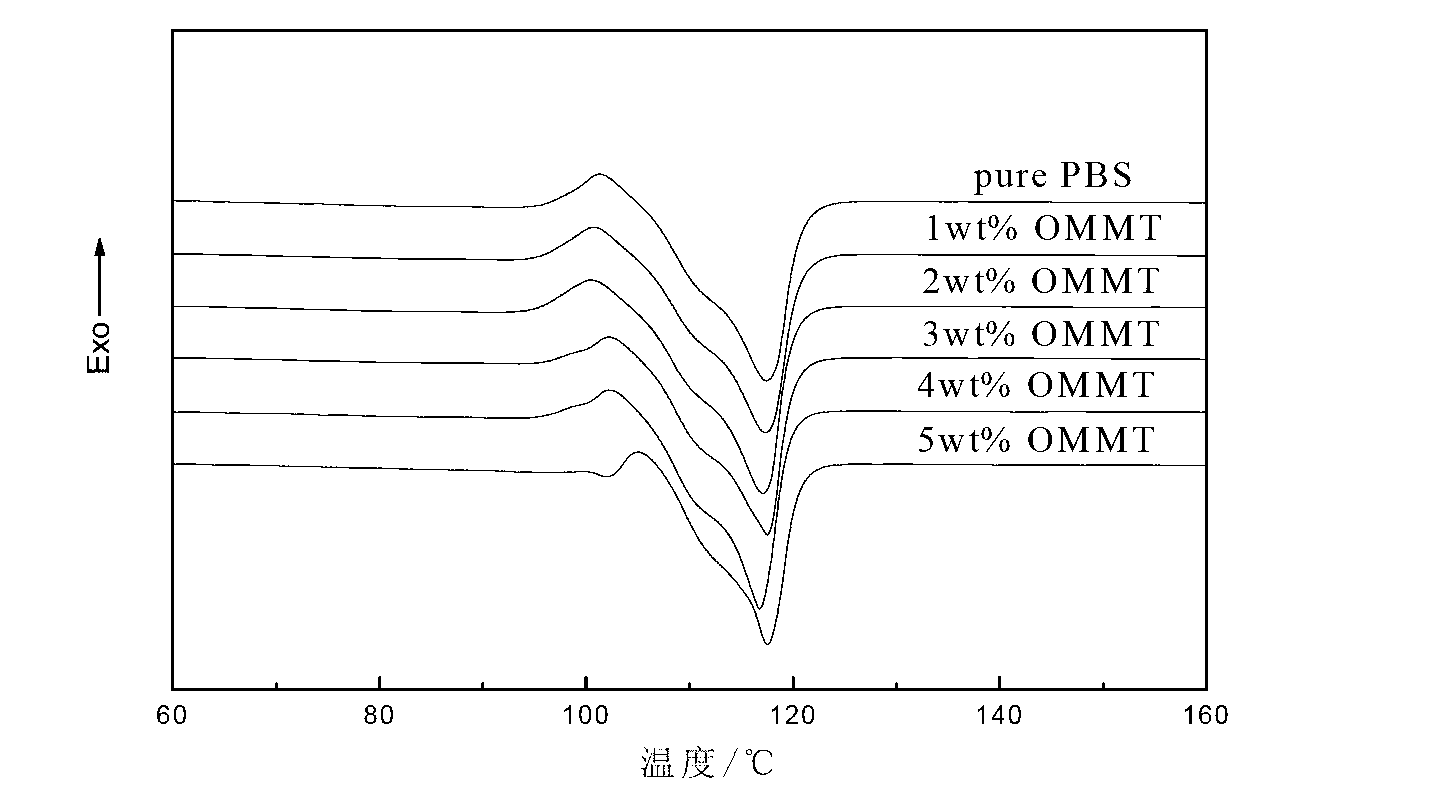

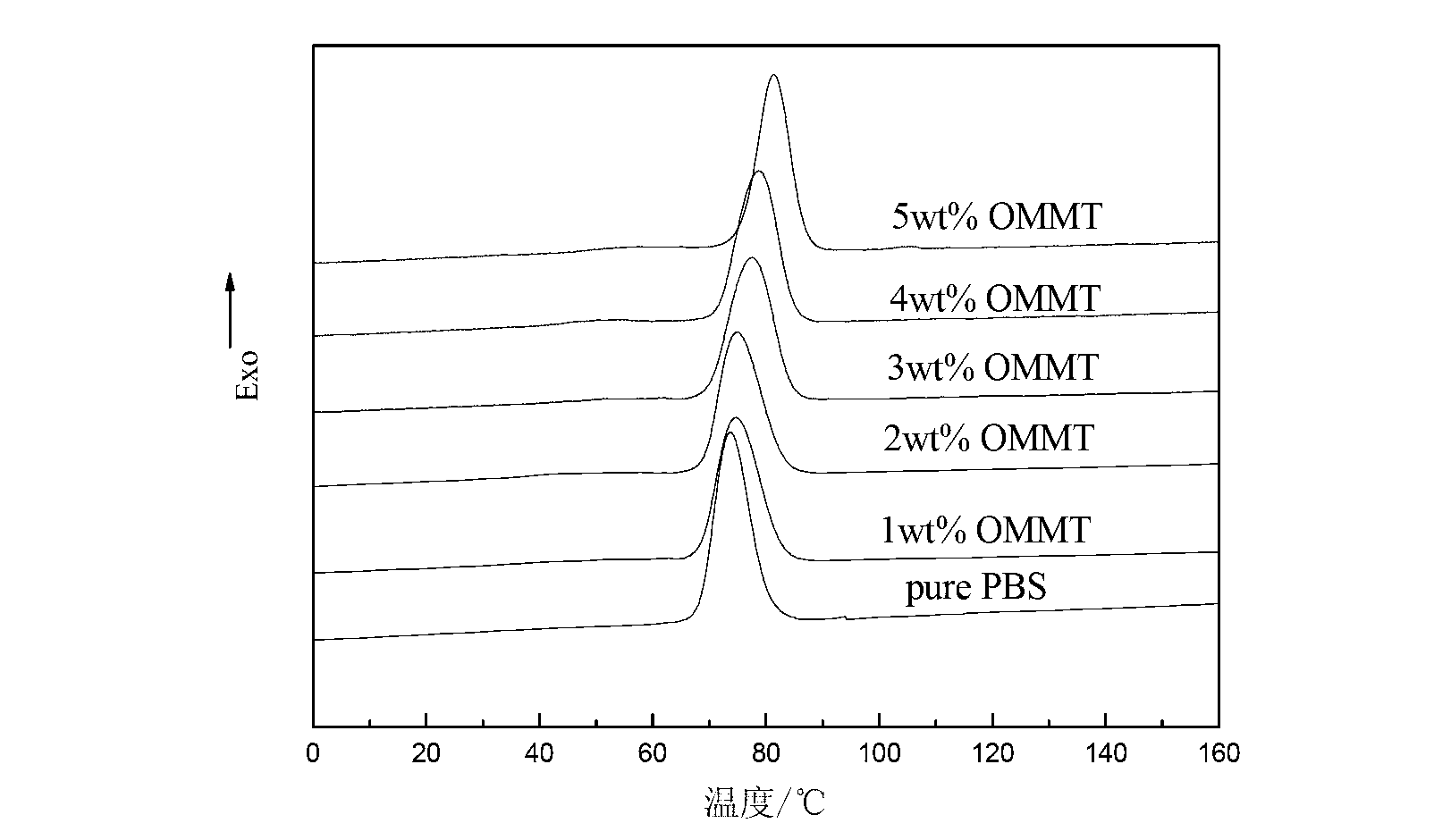

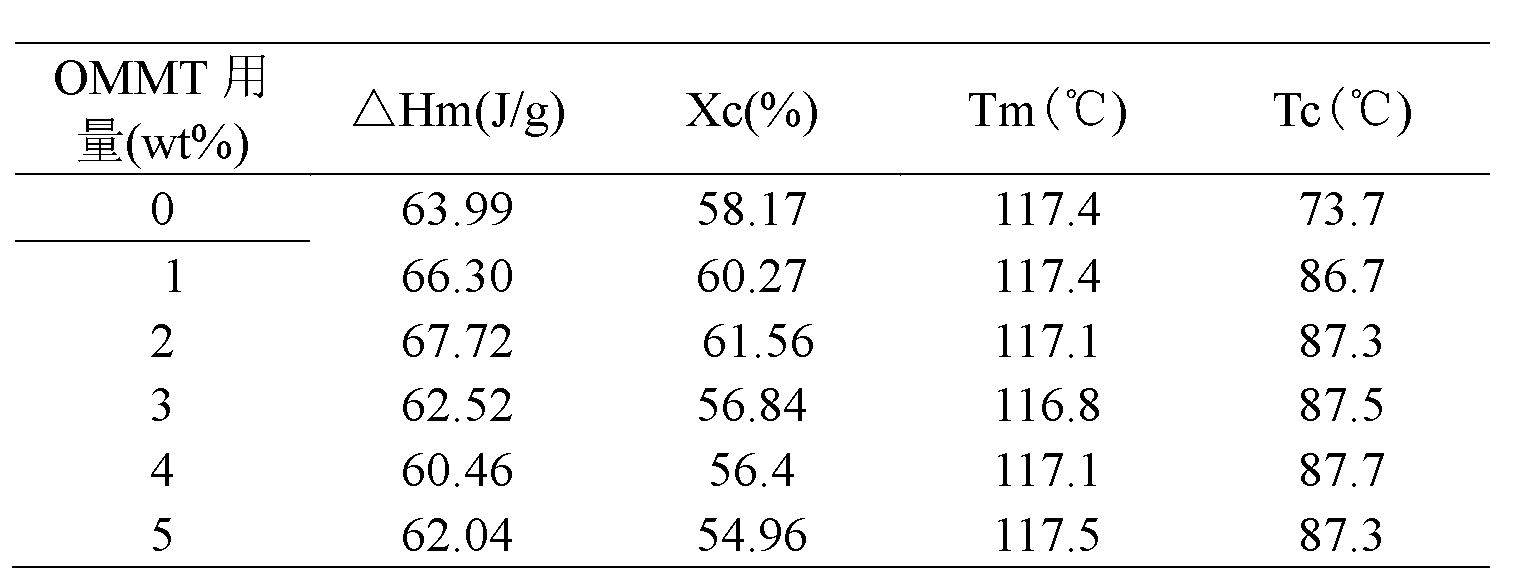

A technology of polybutylene succinate and nano-composite material is applied in the field of biodegradable materials, which can solve the problem of restricting the expansion and application of fully biodegradable materials, hindering the application of polybutylene succinate, and affecting the application of polybutylene succinate. Butanediol ester performance and other issues, to achieve the effect of obvious toughening effect, reduced crystallinity, and increased crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of polybutylene succinate / organic montmorillonite nanocomposite, the steps are:

[0025] (1) Add OMMT to dry PBS, the dosage of OMMT is 1% (wt) of PBS, after mixing evenly, the OMMT / PBS mixture is obtained;

[0026] (2) Put the OMMT / PBS mixture into the twin-screw extruder for extrusion, the screw speed is 30rpm, and the temperature of each section of the twin-screw extruder is respectively set as: feeding section 100°C; melting section 15°C; homogenization section 120°C; The machine head is at 115°C. After extrusion, it is water-cooled and pelletized to obtain the product.

Embodiment 2

[0028] The dosage of OMMT is 2% (wt) of PBS, and its preparation method is the same as in Example 1.

Embodiment 3

[0030] The dosage of OMMT is 3% (wt) of PBS, and its preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com